I move the Wort from the MLT to the Brew Kettle through the filter. Not much left. My MLT is now bottom drain so I no longer have the 1.26 gal dead space. We normally brew 22 to 27 gal batches so that loss in not an issue. We used to take all the dead space into consideration, flushing when we could. We have a fixed manifold that we also flush. We simply added grain and volume to get the desired final fermentor volume.Only issue I see with a strainer is the dead volume it contains. It’s ultimately lost unless you sparge through it too.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BruControl: Brewery control & automation software

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

It looks like it is limited to 158F. Do you use it for mash and sparge?A bit pricy but no moving parts

https://www.ebay.com/itm/SM6001-IFM...8985?_trksid=p2349526.m4383.l4275.c2#viTabs_0

RiverCityBrewer

Well-Known Member

I use the IFM SM6004 series which can be found for <$50 fairly easily. Main difference is 4-20ma outputs instead of pulse. Wetted parts are 316 SS, PEEK, and FKM, all of which have temp ratings well over 200F, so I'm guessing the media temperature rating has more to do with the electronics. To try and allow the most heat shedding possible, I mounted the sensors in the best free air space I could find. All that said, I run them on my HLT, MLT, and kettle and have pushed and sustained temps up well over 200F with no issues.

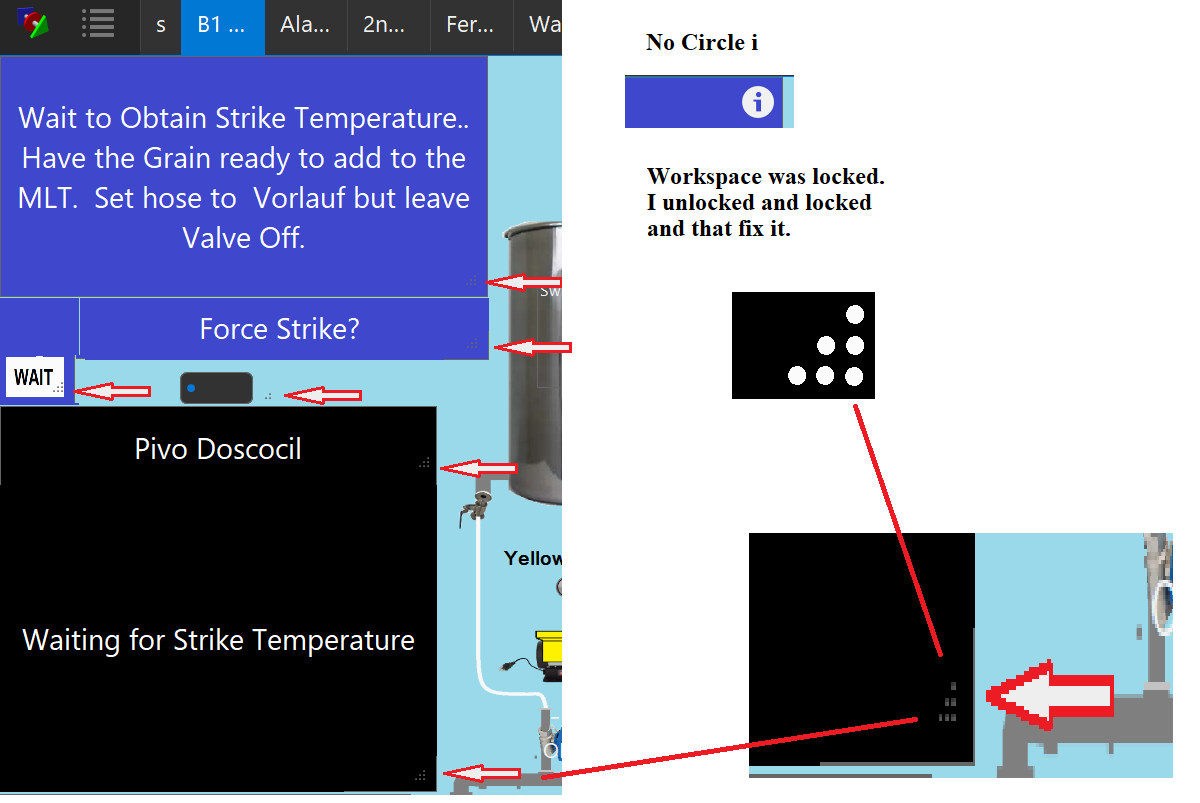

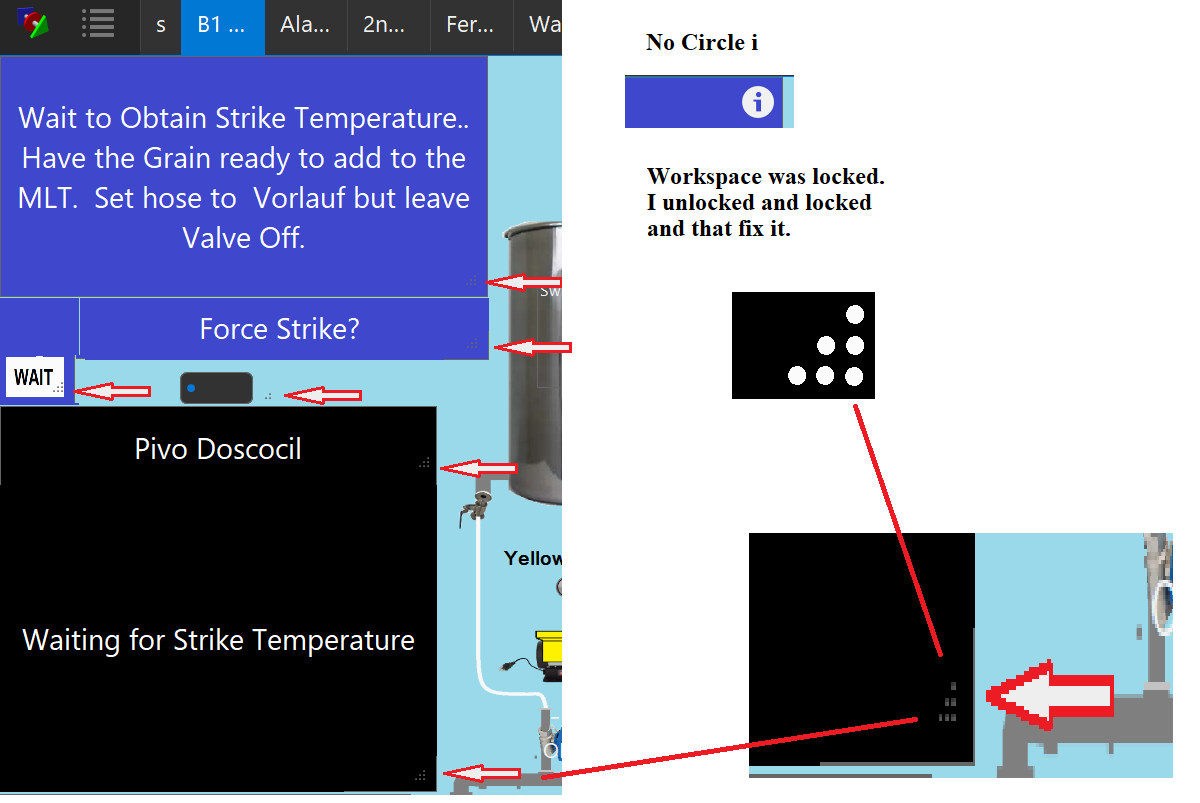

I still have issues with Elements resizing on their own. I just happen to notice that the little move dot trianges in the bottom right of the Element were there even though the workspace wqas locked, I unlocked and relocked, and the move widget disappeared as it was supposed to, This is the first time I noticed this.

Can you post or send pics/screen shots of what you are seeing?

unfortunately not. If it happens again I will take a screen shot. This is a replicate of what I saw: I could resize while locked

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

Just opened BruControl. Did not use the Lock or Unlock at the top. It was locked, I ran a few scripts (starting ones) and I noticed the little resize widget were on all the Elements) Once again, unlocked and relocked and issue gone. I closed BruControl. I opened BruControl and the Widgets once again (no scripts run) were there even though it was locked. This was version 1.1 Build 22 . I will now Open BruConrol and toggle the Lock Icon fcrom now on.

Attachments

ooob44

Member

@oakbarn @BrunDog I observe the same thing. If you lock the workspace, close BruControl, then start BruControl, the workspace will still be locked when the software launches but the elements are able to be resized via mouse in the bottom right corner of the element. If you unlock then relock the workspace, the ability to resize will go away as intended.

This may be a cuase of all the resizing issues I have been having regarding when I am working on the workspaces, It may have been that I was resizing Elements when it was locked and I was not paying attention. I have my resize to 1 x 1 when I am building.@oakbarn @BrunDog I observe the same thing. If you lock the workspace, close BruControl, then start BruControl, the workspace will still be locked when the software launches but the elements are able to be resized via mouse in the bottom right corner of the element. If you unlock then relock the workspace, the ability to resize will go away as intended.

OK, got it. Thanks!

exoticatom

Well-Known Member

unfortunately not. If it happens again I will take a screen shot. This is a replicate of what I saw: I could resize while lockedView attachment 754206

Hi all,

@BrunDog

My setup is to start BC after reboot. So if login to terminal session of my PC, after the restart, I have the same issue, always.

Check this video:

If you unlock/lock it disappears.

cheers evryone

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

So these are npt threads without taper and an oring to seal, so they work with the BSP fitting on the SM6004?FYI, Blichmann quick connectors fit them fine and make for as compact as a connection as you can get.

Edit: For reference, here are some pictures.

RiverCityBrewer

Well-Known Member

Yes, that's correct.

dstein1nine

New Member

- Joined

- Jun 30, 2021

- Messages

- 4

- Reaction score

- 0

Has anyone tried interfacing a Coriolis flow meter via Profibus DP and the mega unishield? Asking for a friend..

RiverCityBrewer

Well-Known Member

I did it via modbus and node red....

dstein1nine

New Member

- Joined

- Jun 30, 2021

- Messages

- 4

- Reaction score

- 0

Thanks for the reply! Unfortunately I believe my meter can only output via Profibus DP (Endress+Hauser promass 83M). I've never worked with PLCs so I was just curious if anyone knew of any software that can run on a virtual machine that could simulate the communication protocol so I would be able to read the meter without getting an actual PLC? I see that there is a beta node red for Profibus DP, but it looks like i would still need a Siemens PLC and adapter to communicate. I appreciate the feedback.I did it via modbus and node red....

Thanks

Profibus runs on RS485 - the physical connection can be made via a shield, but I don't know about the communication layer, especially if it needs to be a master. There are multiple videos / project reviews online, but I didn't dig in to see what it would take.

RiverCityBrewer

Well-Known Member

I'm not familiar with Endress+Hauser, but many sensors with *newer* busses have a fallback to modbus. You might poke around the manual for your specific model and see if that is an option. If you can output modbus, I can help you get it into node-red and thus BC (if you have the correct license).

dstein1nine

New Member

- Joined

- Jun 30, 2021

- Messages

- 4

- Reaction score

- 0

Thanks for the feedback. I'll keep digging into it and see what I can put together.

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

A couple of questions:

I bought some IFM flowmeters off ebay. For 4-20mA output, is anyone using something like this for voltage conversion, or just a simple resistor solution?

https://www.amazon.com/Ximimark-Con...1641916320&sprefix=current+to+,aps,143&sr=8-2

Second question, what size sightglass works for monitoring wort clarity while recirculating and oxygenating?

I bought some IFM flowmeters off ebay. For 4-20mA output, is anyone using something like this for voltage conversion, or just a simple resistor solution?

https://www.amazon.com/Ximimark-Con...1641916320&sprefix=current+to+,aps,143&sr=8-2

Second question, what size sightglass works for monitoring wort clarity while recirculating and oxygenating?

Just a simple 250 ohm resistor works fine.

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

What size site glass do you recommend for monitoring MT recirculation?

It depends. Are you building a system that will be hard piped and not disassembled for cleaning? If so then you want to match the same size as the piping you are going to use. I use 19mm TC piping and matching 19mm sight glasses on my system. If you are going to take things apart and manually clean them then it's not as important.

And regarding the 4-20mA outputs, I have several of the same IFM flow/temp sensors. For most 4-20mA outputs I use a 250 Ohm resistor that converts the signal to 1-5V. However, the temperature range for these only goes to 176F. If you plan on exceeding this temperature then the output will go above 20mA and could damage the analog input(s). I use 232 ohm resistors for the temperature outputs so the analog input never goes above 5V.

And regarding the 4-20mA outputs, I have several of the same IFM flow/temp sensors. For most 4-20mA outputs I use a 250 Ohm resistor that converts the signal to 1-5V. However, the temperature range for these only goes to 176F. If you plan on exceeding this temperature then the output will go above 20mA and could damage the analog input(s). I use 232 ohm resistors for the temperature outputs so the analog input never goes above 5V.

Last edited:

No smaller than any tubing that you are using. We use 1 inch TC in a hard piped manifold just before the plate chiller. Our only use is to see when the last of the wort goes into the plate chiller when we flush our manifold so we can get the wort in the manifold to the fermentor.

un caught error end if

I have a script to reposition valves that used a series of if endif to select the correct configuaration of the valves.

I have a global value that sets the configuration of the valves and in my main brew process the global is set to the correct number for the desired configuration. This is used for the if end if selection. The configuartion script is then started and repositions the valves.

There is a nested if in one of the if endif sections

I made and error and had the endif as end if with a space.

It did not throw an error but was not logically working except before the offending end if error. After that it just ended. (stopped the script).

I fixed the end if to endif and all works normally.

I have a script to reposition valves that used a series of if endif to select the correct configuaration of the valves.

I have a global value that sets the configuration of the valves and in my main brew process the global is set to the correct number for the desired configuration. This is used for the if end if selection. The configuartion script is then started and repositions the valves.

There is a nested if in one of the if endif sections

I made and error and had the endif as end if with a space.

It did not throw an error but was not logically working except before the offending end if error. After that it just ended. (stopped the script).

I fixed the end if to endif and all works normally.

I got one of the new T Mobile 5G internet Sysytem.

It has some issues in that it only allows DCHP and not reserved Static IPs.

It may reset itself quite often if I read the blogs correctly.

Additionally, there is no way to see what devices are connected. I cannot see a list of connected devices. I called their tech support which was very bad. They had no idea of what I wanted. In fact, they were looking up a "Help" document and they could not understand something like a "Static IP".

I set up a local LAN without the internet. I plan to connect the computer to the internet every couple of weeks for the License.

Are there any issues I should be aquantied with regarding this type of setup?

It has some issues in that it only allows DCHP and not reserved Static IPs.

It may reset itself quite often if I read the blogs correctly.

Additionally, there is no way to see what devices are connected. I cannot see a list of connected devices. I called their tech support which was very bad. They had no idea of what I wanted. In fact, they were looking up a "Help" document and they could not understand something like a "Static IP".

I set up a local LAN without the internet. I plan to connect the computer to the internet every couple of weeks for the License.

Are there any issues I should be aquantied with regarding this type of setup?

Your router does not need to know about devices

with static IP addresses. You just need to make sure they are outside the router’s DHCP assignment pool so it doesn’t assign the same address as your interface.

Most routers will keep assigning the same IP to connected clients, so if you keep it connected, it should hold the same reservation. You can find it on the network via Fing or Discovery apps.

with static IP addresses. You just need to make sure they are outside the router’s DHCP assignment pool so it doesn’t assign the same address as your interface.

Most routers will keep assigning the same IP to connected clients, so if you keep it connected, it should hold the same reservation. You can find it on the network via Fing or Discovery apps.

- Joined

- Oct 25, 2008

- Messages

- 146

- Reaction score

- 22

Is there a tradeoff with using a smaller resistor? I am planning on using a 3.3V interface. Based on this I would need 165ohm for 20mA or 132ohm for 25mA. I have in hand 100ohm which would mean I would use 0.4 to 2V of the range (at 4-20mA). With 10bit resolution, 1.56mV per step. Typically for 0-5V applications this is 4.9mV per step. Does the microcontroller have the ability to read steps of 1.5mV? I read somewhere that people set voltage ranges of 0-1V. I am not that worried about ordering more resistors, I am just trying to understand this a little better. When I try to search the voltage resolution of the microcontroller, it just keeps coming back with 4.9mV for 10bit with 0-5V range.And regarding the 4-20mA outputs, I have several of the same IFM flow/temp sensors. For most 4-20mA outputs I use a 250 Ohm resistor that converts the signal to 1-5V. However, the temperature range for these only goes to 176F. If you plan on exceeding this temperature then the output will go above 20mA and could damage the analog input(s). I use 232 ohm resistors for the temperature outputs so the analog input never goes above 5V.

Good question! You can reduce the input voltage range, but you reduce accuracy by doing this. Signal:noise ratio goes down. I’d use the full range - worth the price of the resistor. If you need, email us and we can mail you some, no cost.

Similar threads

- Replies

- 45

- Views

- 5K

- Replies

- 29

- Views

- 7K

- Replies

- 51

- Views

- 10K

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)