broox

Member

I just picked up a Maytag MSS25N4MKZ side-by-side refrigerator to replace my small keezer setup, so I'm starting a build thread!

I went with the side-by-side because my wife and I wanted more general refrigerator and freezer space alongside the homebrew kegs... The keezer was kind of annoying for throwing extra drinks in, and the side-by-side configuration just seemed like the best use of space for storing extra stuff.

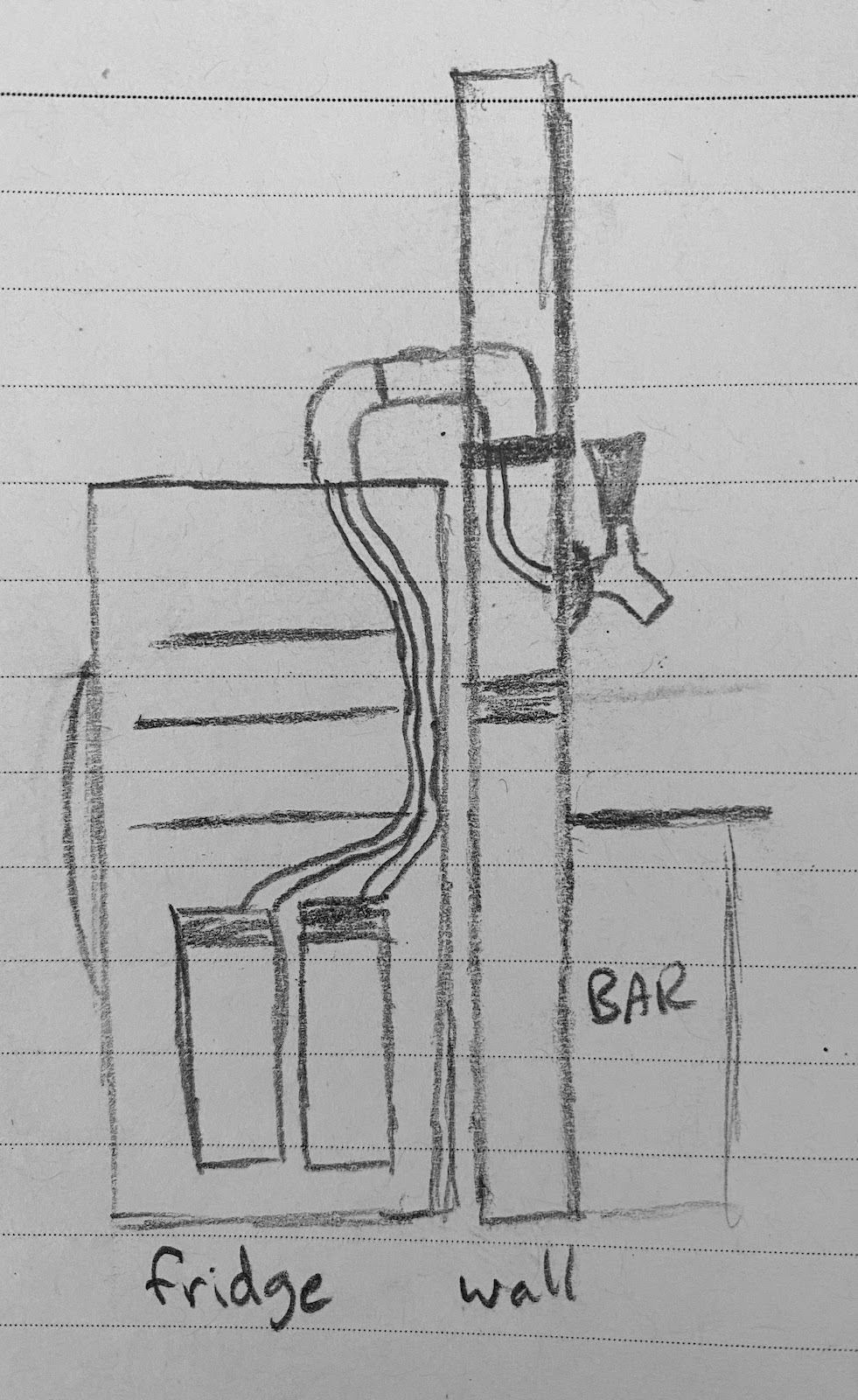

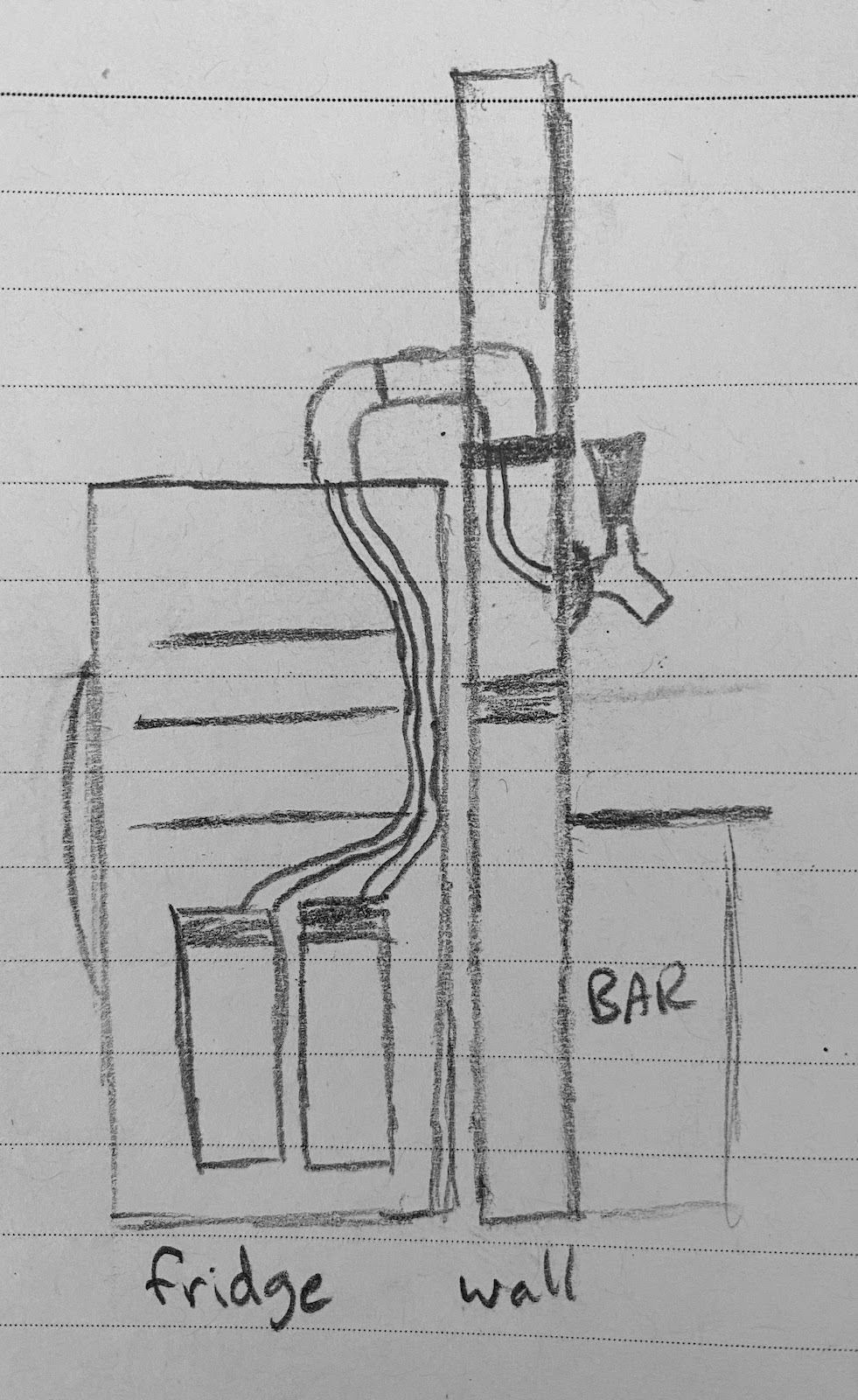

SO... I'm planning to store kegs in the bottom half of the fridge, but I would like to plumb the tap lines into the wall that sits behind the refrigerator - with taps on the other side.

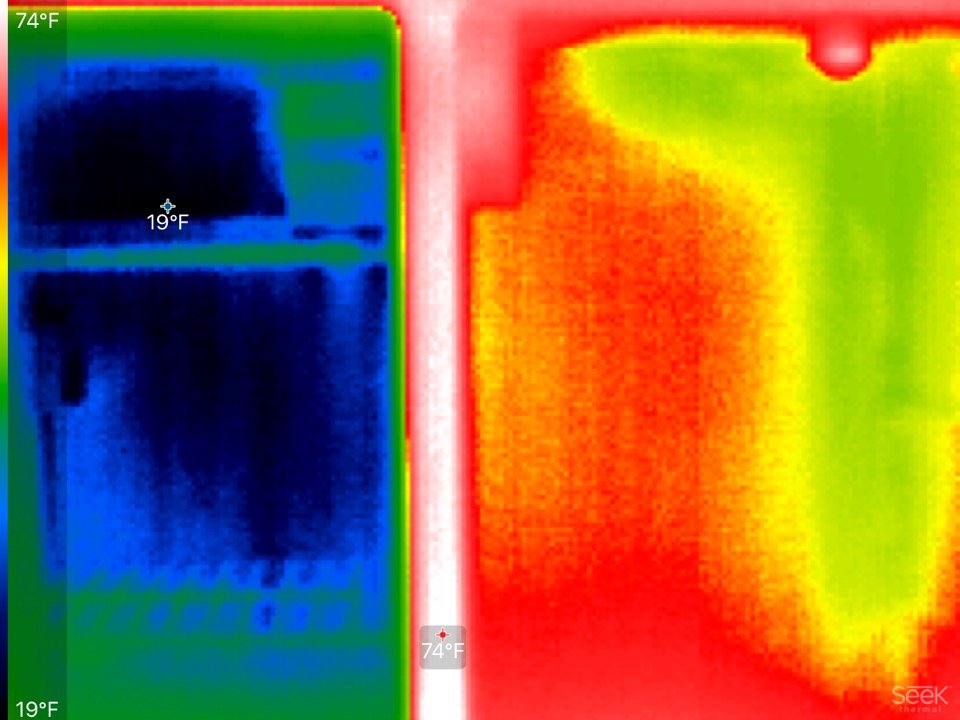

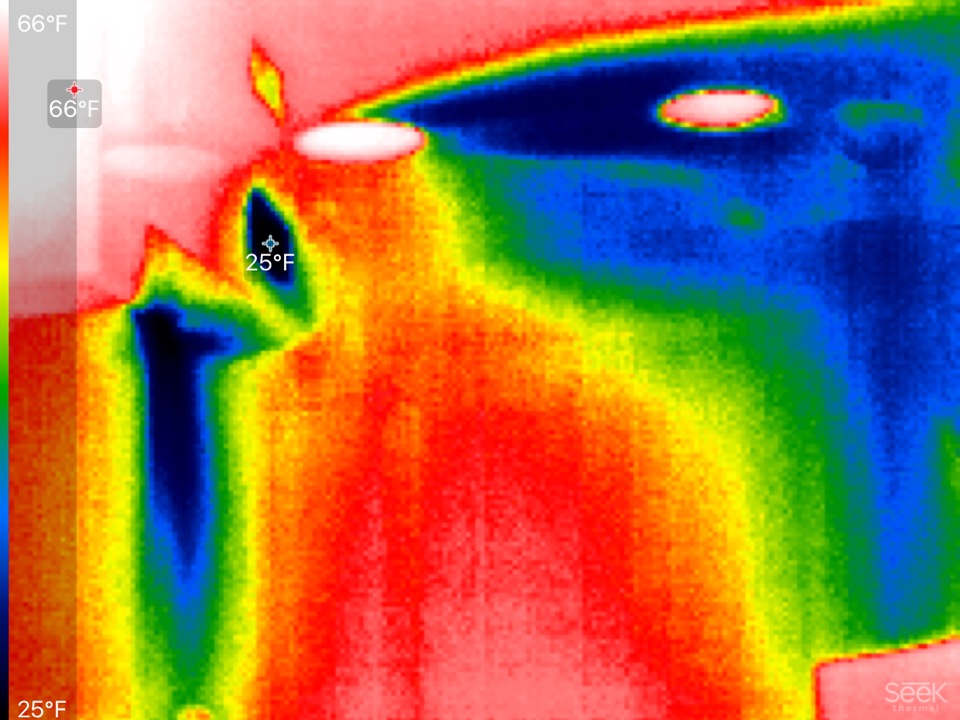

I highly doubt I can plumb lines straight through the back of the fridge, as I'm pretty sure this is where most of the coolant lines are. I don't really want to plumb out of the side of the fridge, just because the plumbing will be in the way.

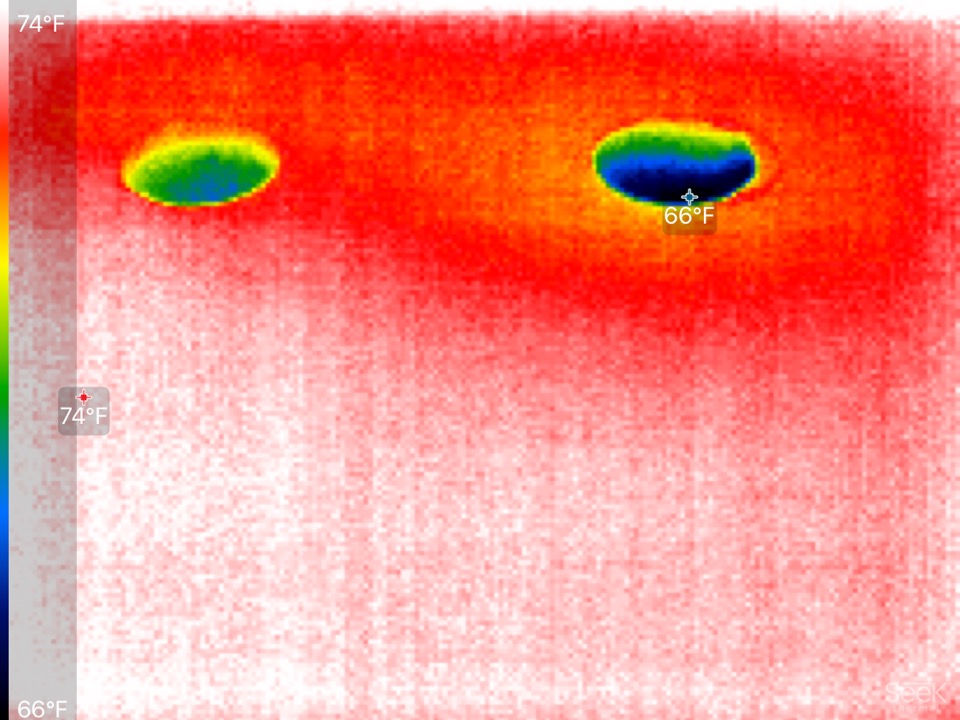

I'm thinking the best way to do this would be to plumb the lines out of the top of my fridge, into the wall behind it to an insulated tap-box that sits between the studs.

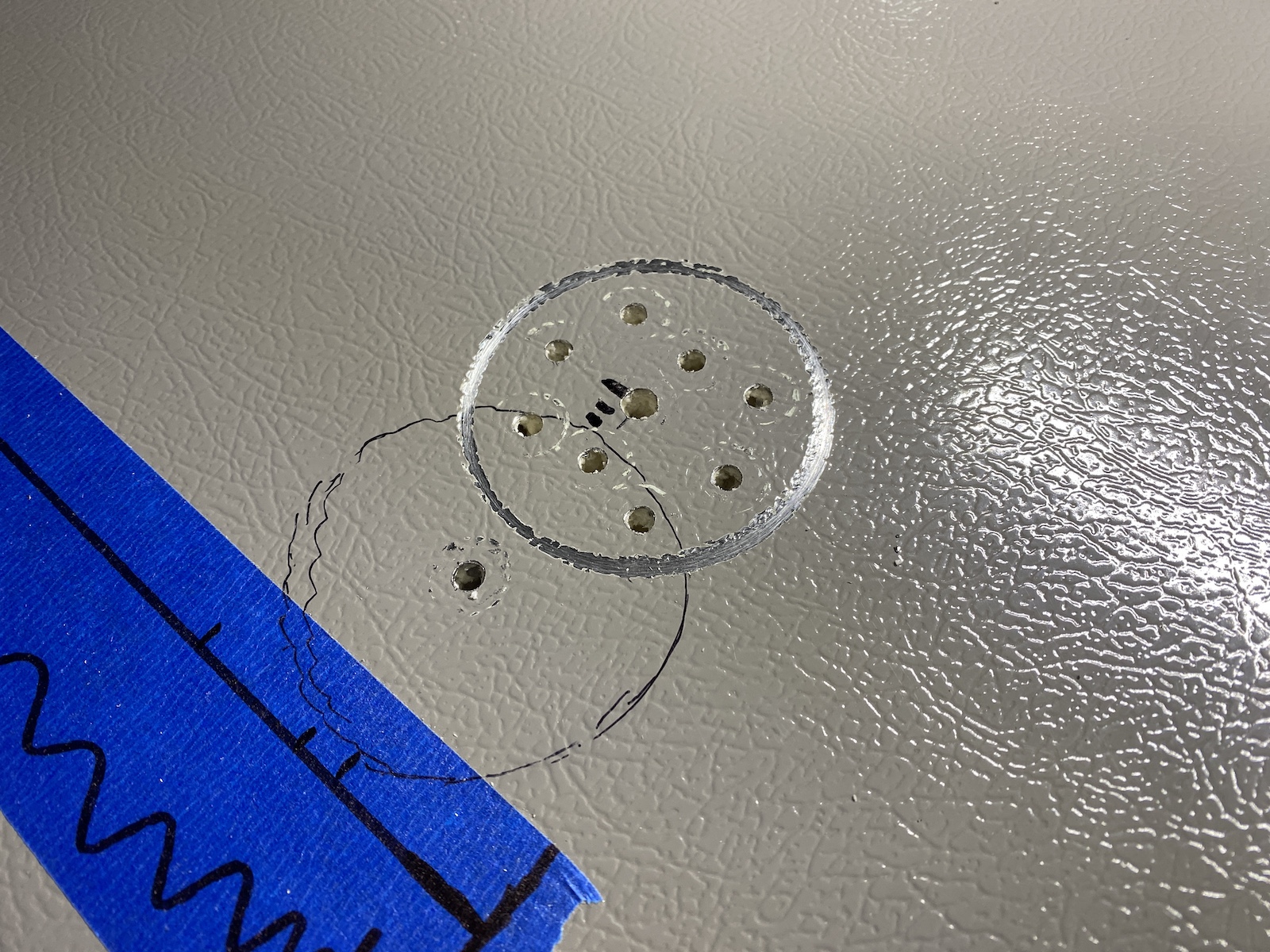

Doing this provides the shortest amount of plumbing at around 2-3'... so I should be able to pretty easily get away with 2 - 2" air ducts, and I'm planning to run 3 taps.

I've never seen anyone run lines out the top of a full-sized fridge, so far starters, does this seem sane? Think I'll have any problems cutting 2" holes in the top of my brand new, full-sized side-by-side? Most new fridges keep all the fragile stuff in the back, right?

In case my description wasn't clear, here's a terrible sketch with even worse proportions:

For searchability, I'm pretty sure the Maytag MSS25N4MKZ is the exact same as the Whirlpool WRS315SNHM / WRS315SNHB / WRS315SNHW

I went with the side-by-side because my wife and I wanted more general refrigerator and freezer space alongside the homebrew kegs... The keezer was kind of annoying for throwing extra drinks in, and the side-by-side configuration just seemed like the best use of space for storing extra stuff.

SO... I'm planning to store kegs in the bottom half of the fridge, but I would like to plumb the tap lines into the wall that sits behind the refrigerator - with taps on the other side.

I highly doubt I can plumb lines straight through the back of the fridge, as I'm pretty sure this is where most of the coolant lines are. I don't really want to plumb out of the side of the fridge, just because the plumbing will be in the way.

I'm thinking the best way to do this would be to plumb the lines out of the top of my fridge, into the wall behind it to an insulated tap-box that sits between the studs.

Doing this provides the shortest amount of plumbing at around 2-3'... so I should be able to pretty easily get away with 2 - 2" air ducts, and I'm planning to run 3 taps.

I've never seen anyone run lines out the top of a full-sized fridge, so far starters, does this seem sane? Think I'll have any problems cutting 2" holes in the top of my brand new, full-sized side-by-side? Most new fridges keep all the fragile stuff in the back, right?

In case my description wasn't clear, here's a terrible sketch with even worse proportions:

For searchability, I'm pretty sure the Maytag MSS25N4MKZ is the exact same as the Whirlpool WRS315SNHM / WRS315SNHB / WRS315SNHW

Last edited: