EmDubeu

Well-Known Member

- Joined

- Feb 21, 2013

- Messages

- 239

- Reaction score

- 46

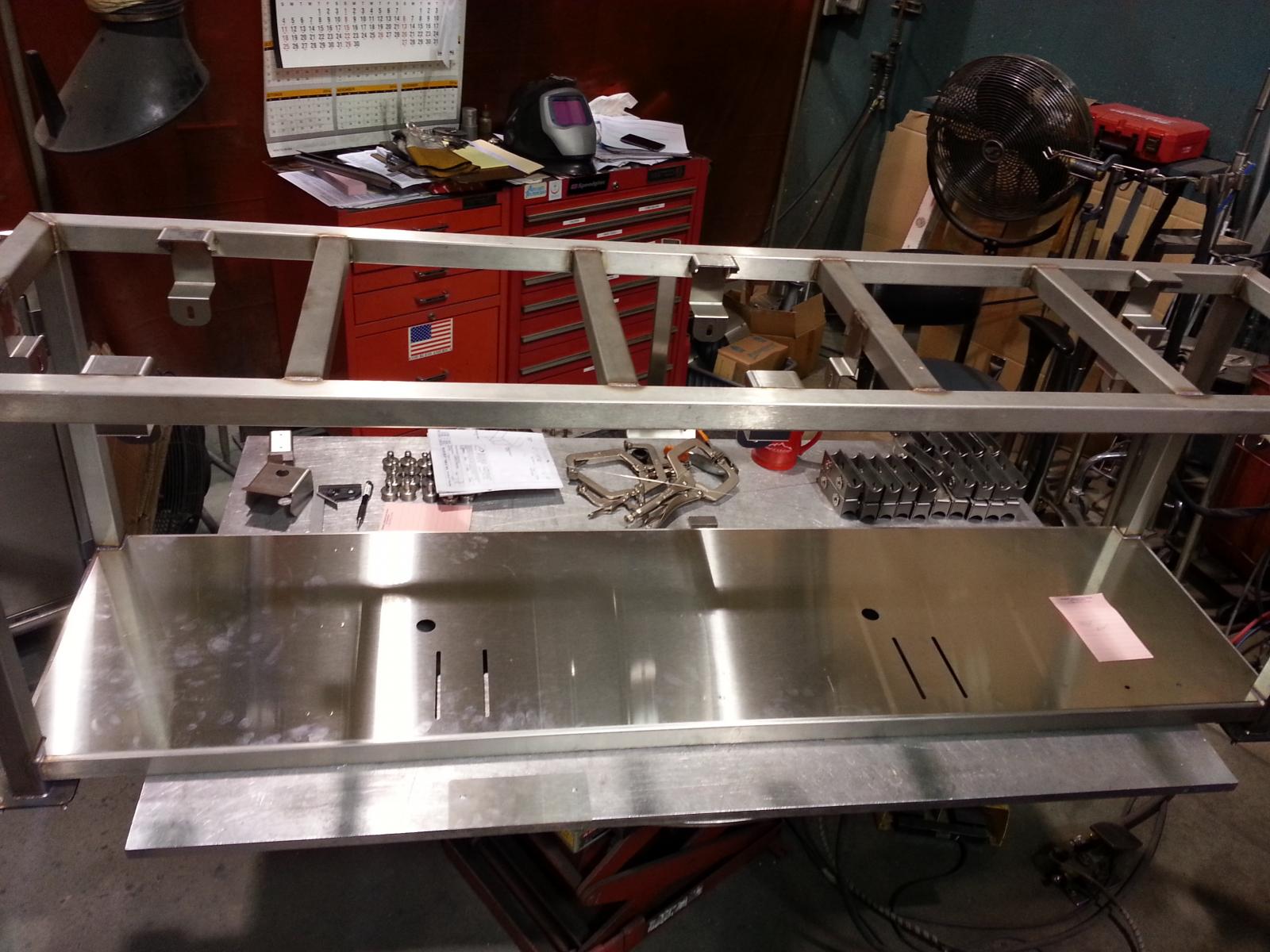

It's finally home. We added the pot filler faucet and we need to plumb it to the filtered water line. The burners, pumps, chiller, and control panel will get installed in the next week and so will the black pipe for the LPG.

Why yes they are custom 15.5 sanke kegs with a corney top welded on. I use them for fermentation. Love them!

I also have a custom corney lid that I had a thermowell welded in. This way I can monitor fermentation temperature and adjust heating or cooling devices in the fermentation chamber as needed.

That is pretty darn slick. I've been considering putting bigger triclover fittings on some sankeys for use as fermentors.. but welding on a corney top is a cool idea..probably cheaper than the TC fittings too..

I just did a scan of the thread and first impression was "those are some great welds!" Really nice workmanship. I'm also jealous.