My first brew in Oct I just let carboy sit in my finished garage. It is war during the day, and cool at night. I am sure the beer fluxed 10 degrees or more daily. Obviously, this was bad.

My second beer, I put it into my temperature controlled office. I taped a SensorPush thermometer to the outside, and I made sure my carboy external temp stayed within margins, between 65 and 72 degrees.

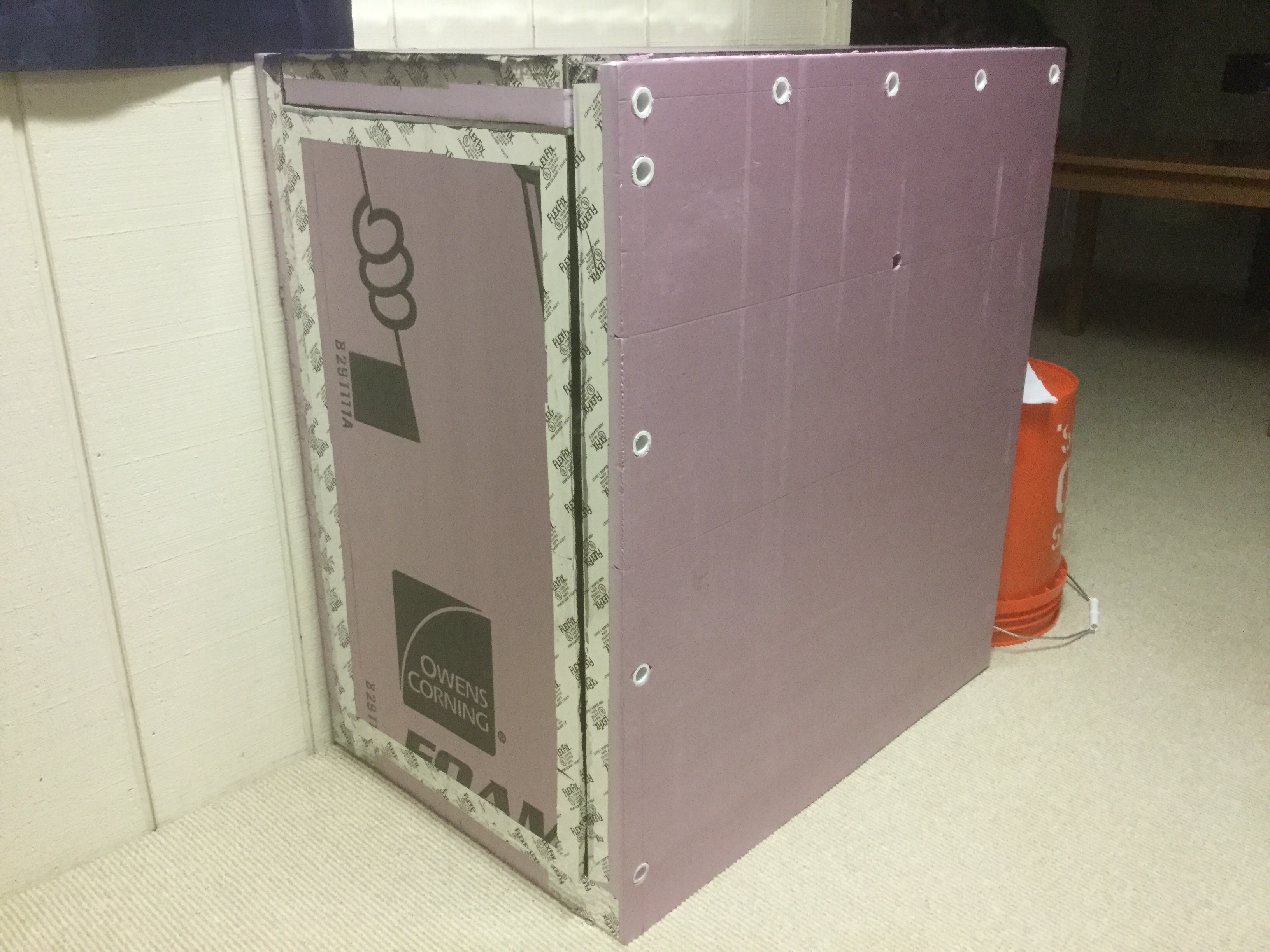

Moving forward, what is the best and most cost effective method for keeping my temp rock steady? Move the carboy into my basement where it is cooler, and use a thermometer lead and a heat wrap to ensure the temp is correct? Those heat wraps are good in a cool environment or for warmer beer... what about cooler brews?

My next brew will be a porter, I have not checked the temp requirements yet. But being able to control the temp for all of the beer that I brew, and pay less than $100 for it would be ideal.

My second beer, I put it into my temperature controlled office. I taped a SensorPush thermometer to the outside, and I made sure my carboy external temp stayed within margins, between 65 and 72 degrees.

Moving forward, what is the best and most cost effective method for keeping my temp rock steady? Move the carboy into my basement where it is cooler, and use a thermometer lead and a heat wrap to ensure the temp is correct? Those heat wraps are good in a cool environment or for warmer beer... what about cooler brews?

My next brew will be a porter, I have not checked the temp requirements yet. But being able to control the temp for all of the beer that I brew, and pay less than $100 for it would be ideal.