schoellhorn82

Well-Known Member

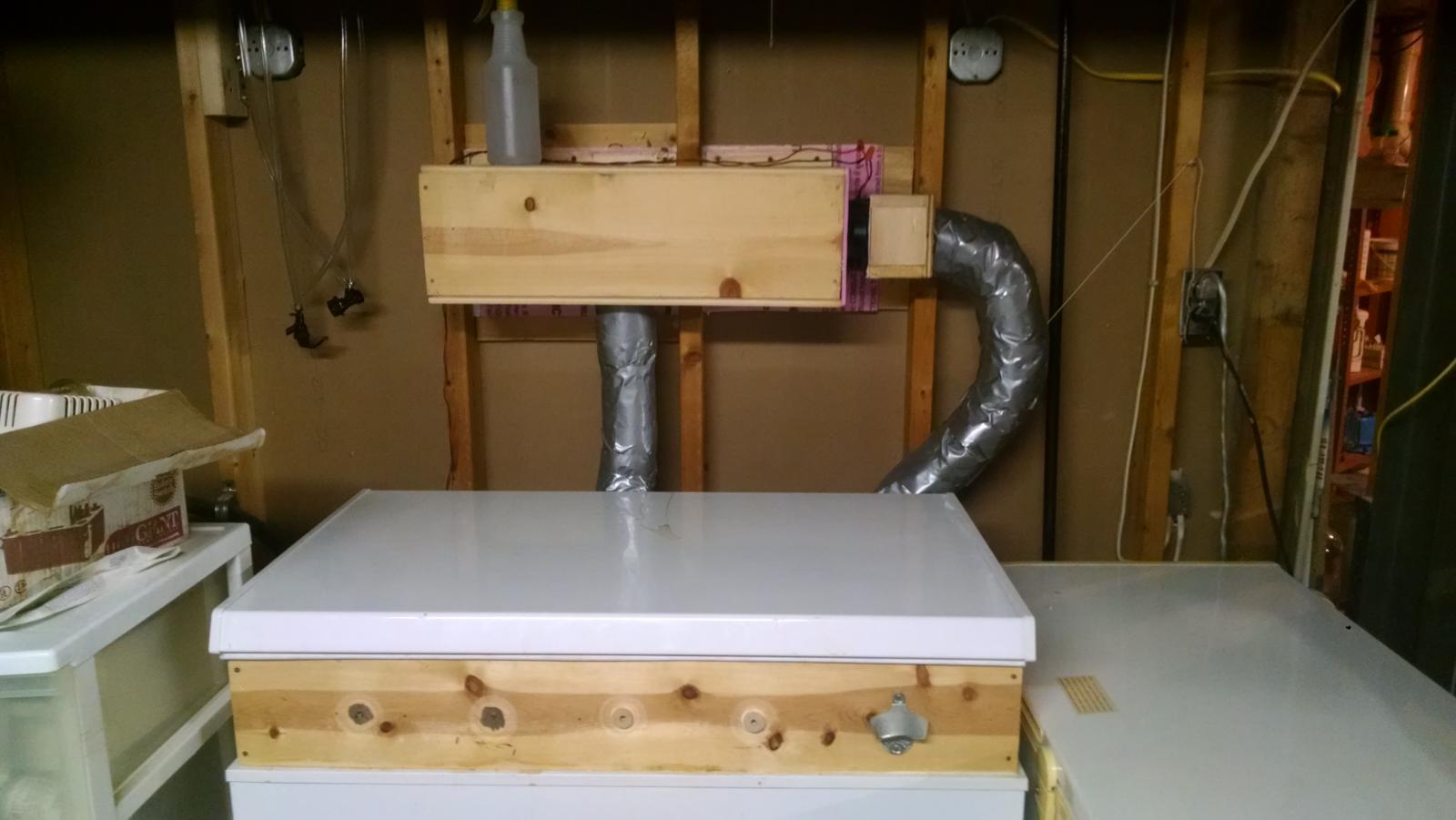

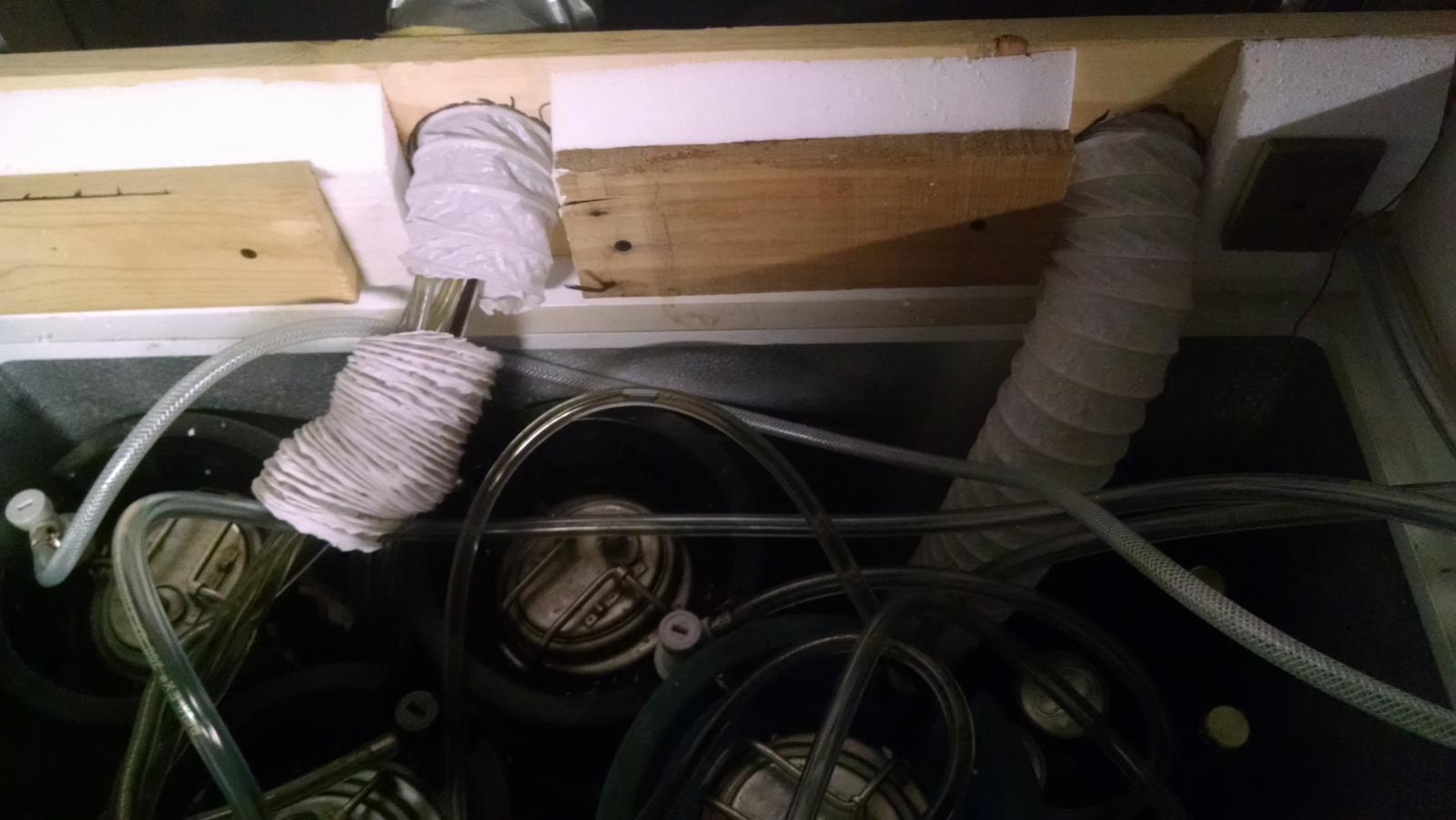

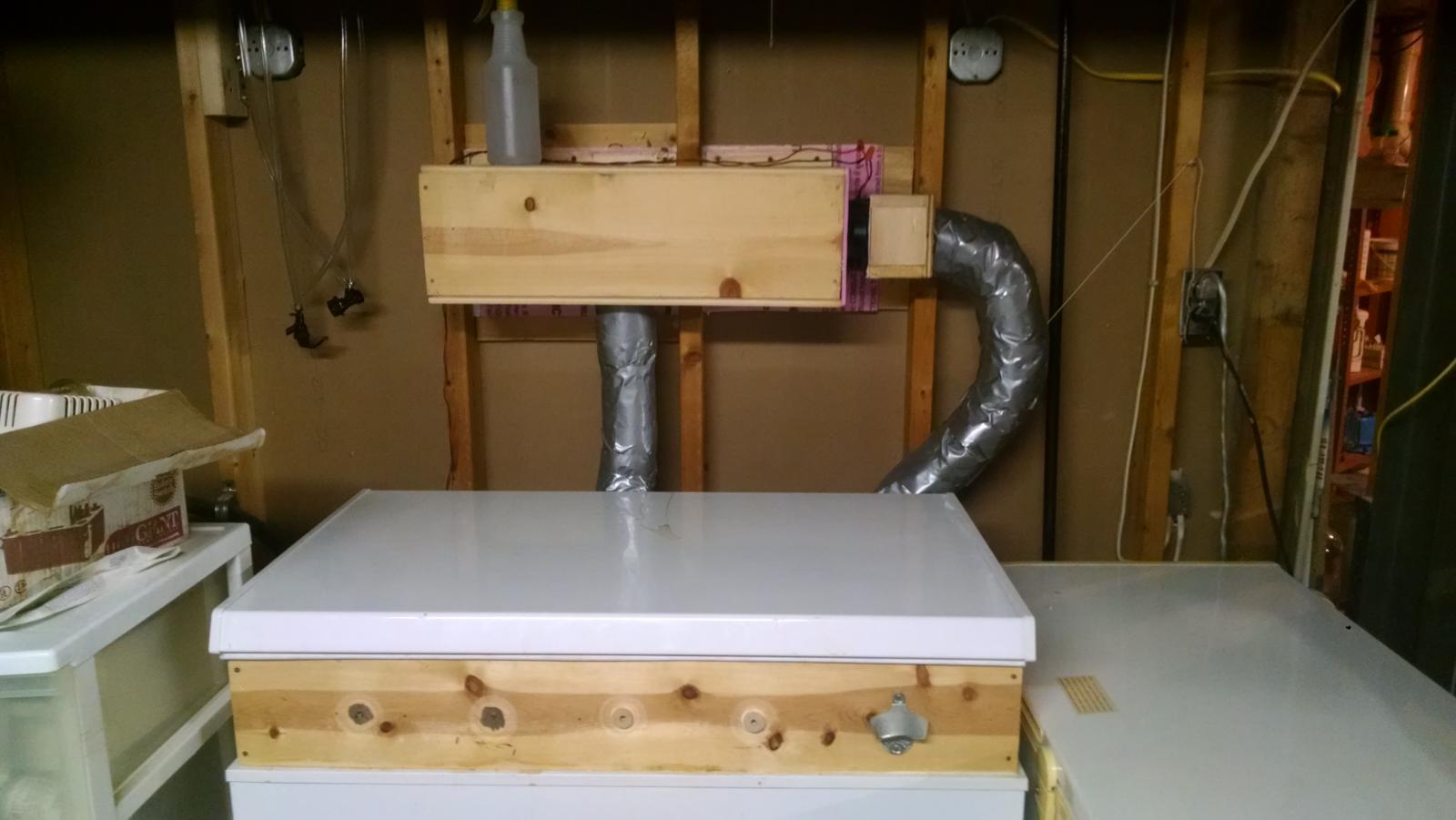

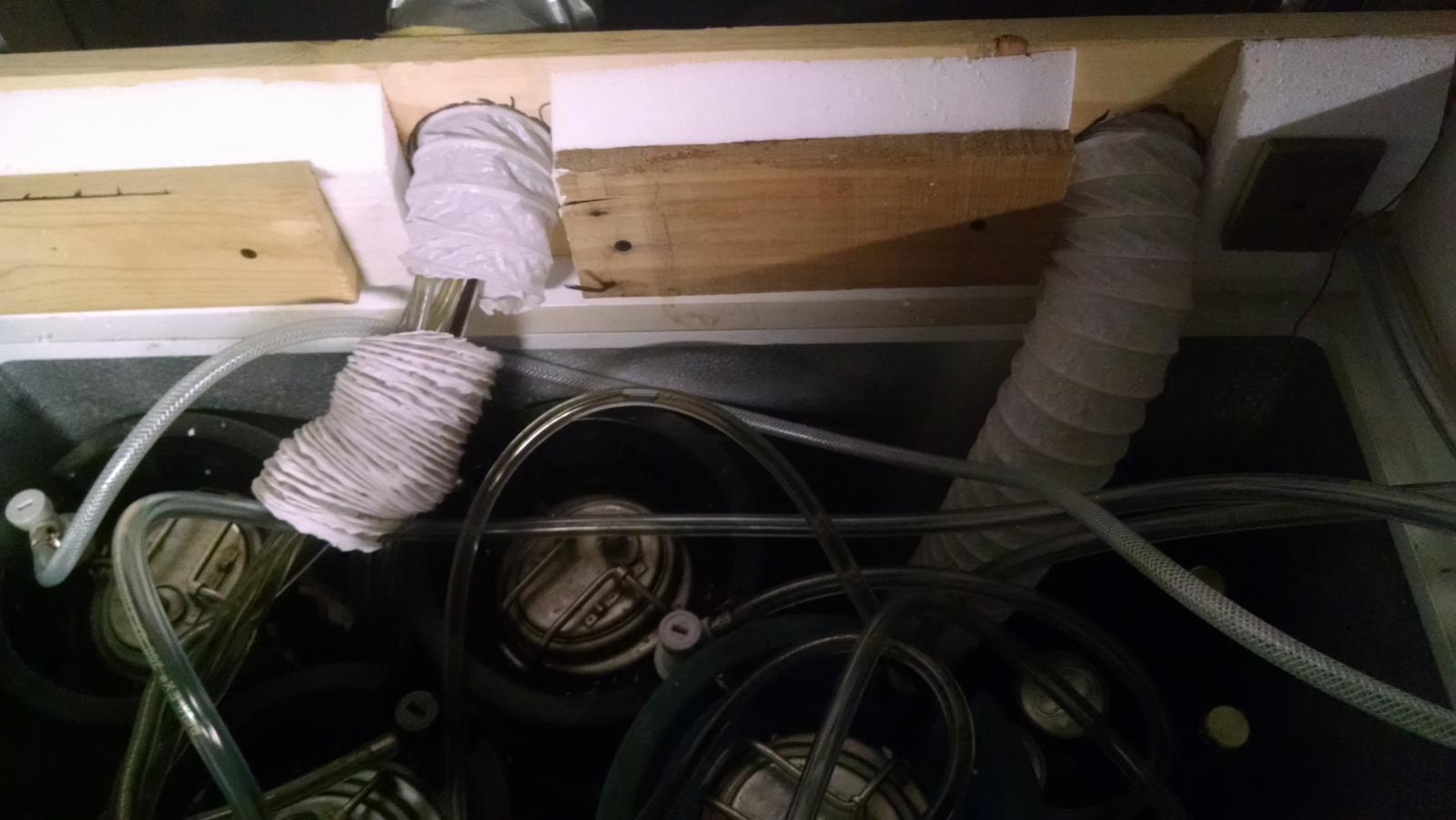

This is the first time I've tried to attach photos so bare with me. If they load, here is my set up. A bow that is 3/4in insulated around everything has a 115v circulating air from the keezer to the box, to the beer lines, then back to the keezer. The trouble i have is the keezer keeps frosting the perimeter and the kegs and is getting very hot, but the temps coming from the box are only around 50dF. An improvement but my lines are getting frozen while still foaming a ****load. the fan is pretty powerful and everything should be insulated enough to keep it cool. It seems like the keezer is overworking to keep the ambient temps down to 33dF but i never seem to reach an equalibrium with my system. It has been running a week with no avail. Any advise would be appreciated.