Mob_Barley

Well-Known Member

Has anyone written a step-by-step guide to wiring a control panel for those that cannot read electrical schematics but can follow instructions well? I did not have any problems with the mechanics of designing and building my RIMS brewery, but not that it is time to wire all the components, I find myself at a disadvantage, I'm electrically challenged...

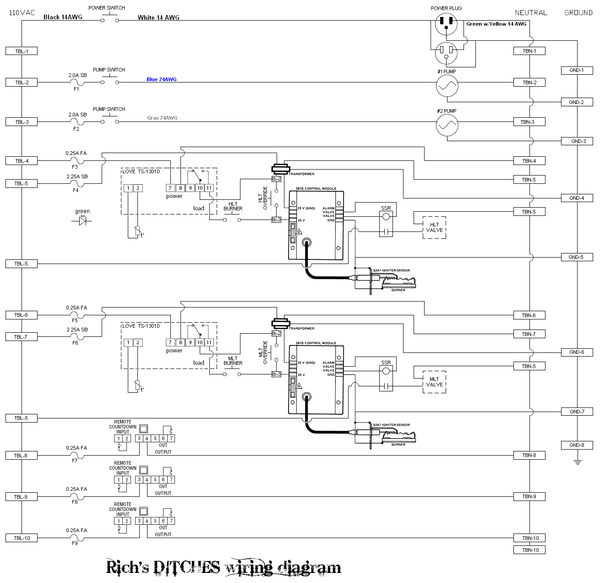

I followed some of the threads and ideas from the forum and designed a pretty complicated system with three dual gas valves with intermittent pilot ignition systems. Two are on Love TS-2 controllers and the boil kettle will simply be switched on and off. I have bought a 24VAC/75A transformer to power the valves. Now I just need some basic instructions on how to wire all the components together in the control panel.

My control panel has switches and LED lights for each pump, each burner, the HLT and MT (along with a Love TS-2 controller for each), and a main power switch. If there is a thread that goes through the whole thing without using pictures of someone's rat's nest of a panel, or complicated (for me) schematics, I can't find one. Maybe someone can direct me to the right place. Thanks for everyone's help thus far.

www.winning-homebrew.com

I followed some of the threads and ideas from the forum and designed a pretty complicated system with three dual gas valves with intermittent pilot ignition systems. Two are on Love TS-2 controllers and the boil kettle will simply be switched on and off. I have bought a 24VAC/75A transformer to power the valves. Now I just need some basic instructions on how to wire all the components together in the control panel.

My control panel has switches and LED lights for each pump, each burner, the HLT and MT (along with a Love TS-2 controller for each), and a main power switch. If there is a thread that goes through the whole thing without using pictures of someone's rat's nest of a panel, or complicated (for me) schematics, I can't find one. Maybe someone can direct me to the right place. Thanks for everyone's help thus far.

www.winning-homebrew.com