yeoldebrewer

Well-Known Member

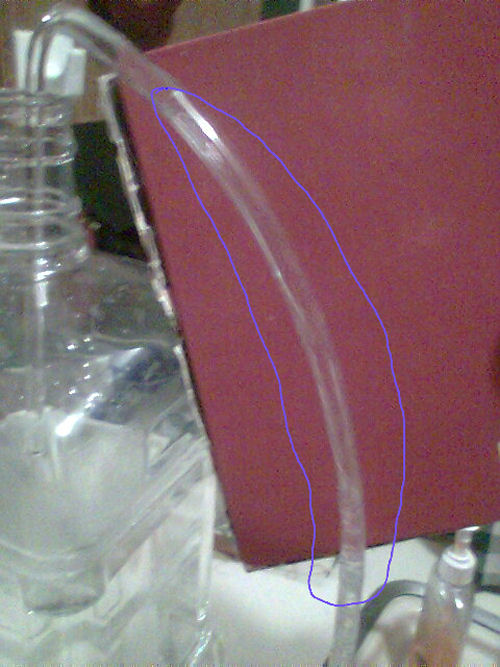

I used my autosiphon to transfer a six gallon batch of Coopers ale from primary to a bottling bucket--first time I have used one. I'm a little concerned because the flow of beer in the tubing seemed to contain voids and maybe bubbles. Air could not have been getting in at the intake so I'm wondering if I'm using this gadget with wrong technique?

Shouldn't the flow of beer appear uniformly liquid throughout the tubing?

Shouldn't the flow of beer appear uniformly liquid throughout the tubing?