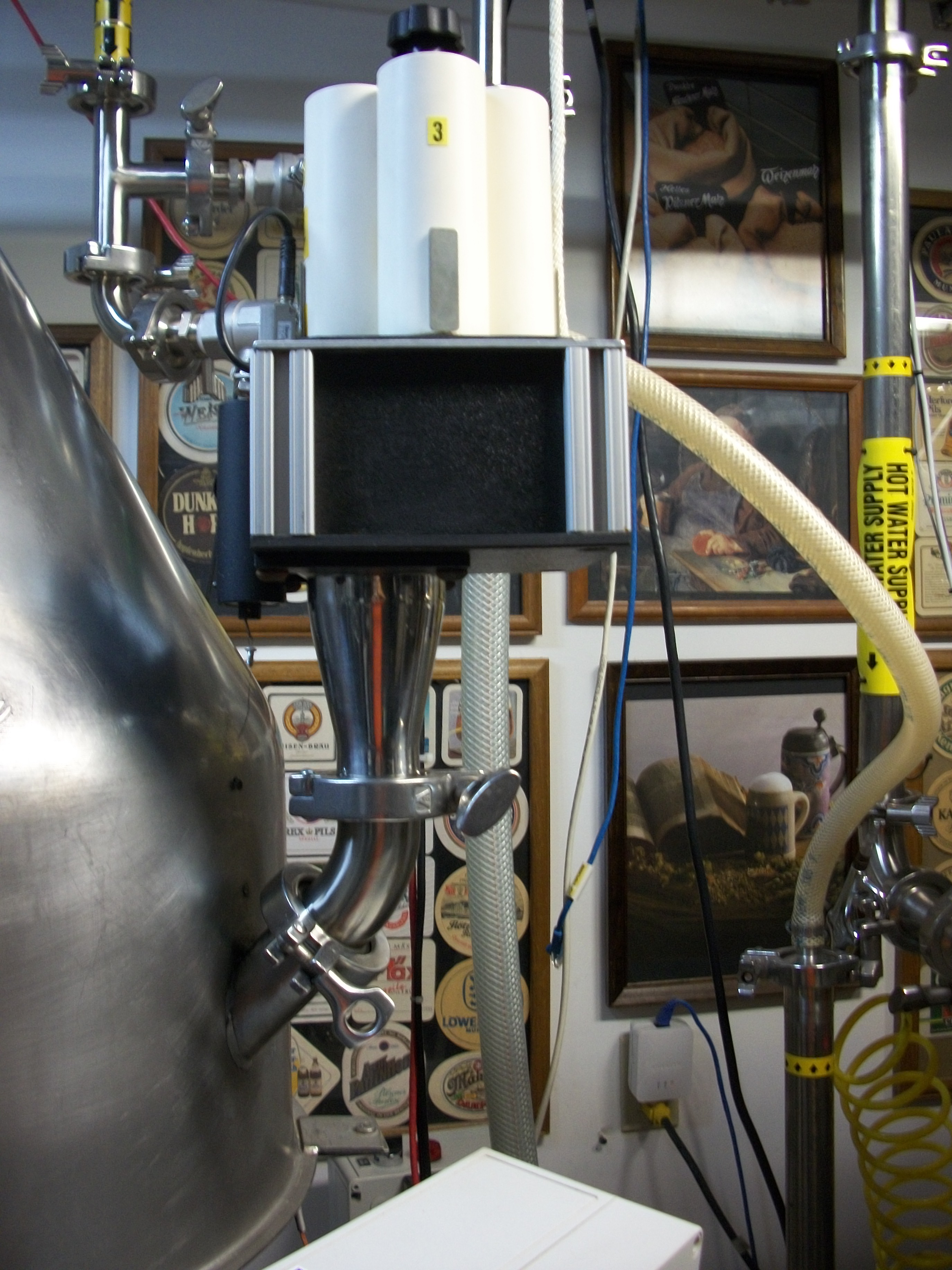

When searching I didn't see a lot of posts on automating boil additions so I decided to post this apart from my main project thread to make it easier to find.

[ame]https://www.youtube.com/watch?v=st8dmIBfVbo&feature=[/ame]

This is a small part of a larger project to fully automate brew day which can be found here: (Automation with Arduino)

https://www.homebrewtalk.com/showthread.php?t=633943

__

[ame]https://www.youtube.com/watch?v=st8dmIBfVbo&feature=[/ame]

This is a small part of a larger project to fully automate brew day which can be found here: (Automation with Arduino)

https://www.homebrewtalk.com/showthread.php?t=633943

__