Hey all,

I have this very frustrating issue with my Arduino controlled electric brew system. I use a PC with a C# interface to communicate over serial with the arduino to send commands such as desired temperatures and to enabled/disable elements, contactors, etc.

Well, there are actually 2 problems but I assume they are related....

Issue 1: The power to my March pump is fed through the main control panel (so it is GFCI protected) where the arduino and all low-voltage components are also mounted. When I manually turn the pump on (with a physical switch located by the pump), 90% of the time the arduino loses connection with the PC and I get serial write errors. This is very frustrating as I have to then unplug the USB connection to arduino, restart my C# program, and start over again....

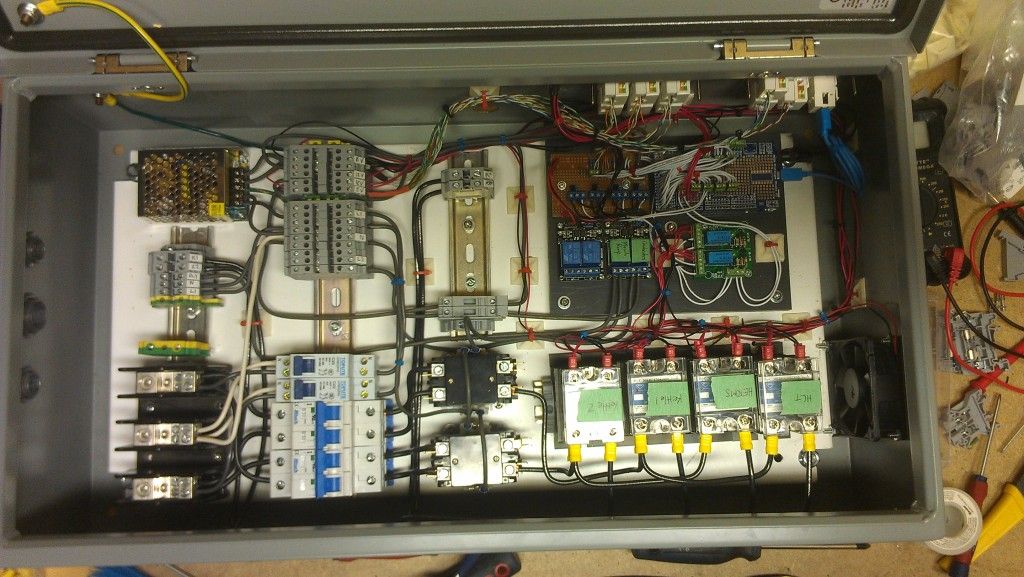

I assume this is due to some sort of electromagnetic interference or something similar....I have tried to keep the low voltage micro-controlled components separate from the high voltage/current lines (see pic below).

Control panel pic (this pic is not in the final state). You can see the arduino and relays mounted in the upper right, where my USB connection to the PC also is. On the far left you see the un-terminated terminal blocks where my pump gets power from, which are sent out through those conduit fittings. Main power feed (from separate 50A Spa panel) is on the lower left at those large terminals, which also enters from that side through conduit.

Issue #2: Very similar to issue #1. I have a "main power" button on my program that sends a signal to a relay to energize the two contactors that feed my elements. The relay is opto-isolated so I assume there is no interaction between the high voltage side and low voltage side of this relay. About 50% of the time when I energize/de-energize the contactors, I get the same communication fault between the arduino and PC.

This same problem existed on my previous control panel, which was an entirely different built with a rats nest of wires. I had assumed the problem was due to the messy wiring... But apparently not.

The arduino is powered from a separate 12 V power supply so it does not rely on the power from the USB connection.

I've tried searching all over for this issue but I have come up empty handed. Has anyone dealt with something like this?

I have this very frustrating issue with my Arduino controlled electric brew system. I use a PC with a C# interface to communicate over serial with the arduino to send commands such as desired temperatures and to enabled/disable elements, contactors, etc.

Well, there are actually 2 problems but I assume they are related....

Issue 1: The power to my March pump is fed through the main control panel (so it is GFCI protected) where the arduino and all low-voltage components are also mounted. When I manually turn the pump on (with a physical switch located by the pump), 90% of the time the arduino loses connection with the PC and I get serial write errors. This is very frustrating as I have to then unplug the USB connection to arduino, restart my C# program, and start over again....

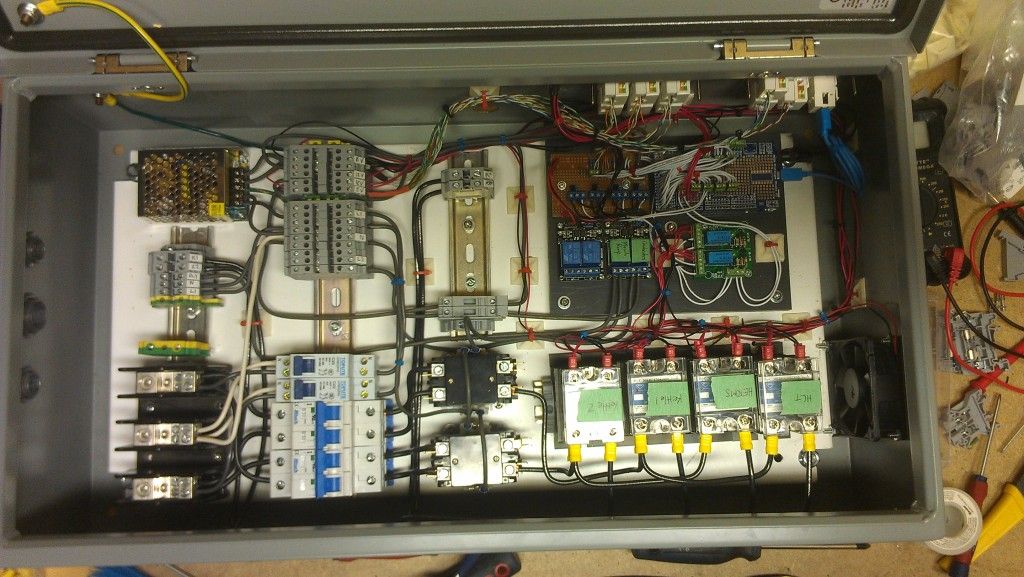

I assume this is due to some sort of electromagnetic interference or something similar....I have tried to keep the low voltage micro-controlled components separate from the high voltage/current lines (see pic below).

Control panel pic (this pic is not in the final state). You can see the arduino and relays mounted in the upper right, where my USB connection to the PC also is. On the far left you see the un-terminated terminal blocks where my pump gets power from, which are sent out through those conduit fittings. Main power feed (from separate 50A Spa panel) is on the lower left at those large terminals, which also enters from that side through conduit.

Issue #2: Very similar to issue #1. I have a "main power" button on my program that sends a signal to a relay to energize the two contactors that feed my elements. The relay is opto-isolated so I assume there is no interaction between the high voltage side and low voltage side of this relay. About 50% of the time when I energize/de-energize the contactors, I get the same communication fault between the arduino and PC.

This same problem existed on my previous control panel, which was an entirely different built with a rats nest of wires. I had assumed the problem was due to the messy wiring... But apparently not.

The arduino is powered from a separate 12 V power supply so it does not rely on the power from the USB connection.

I've tried searching all over for this issue but I have come up empty handed. Has anyone dealt with something like this?