Velnerj

Simul justus et potator

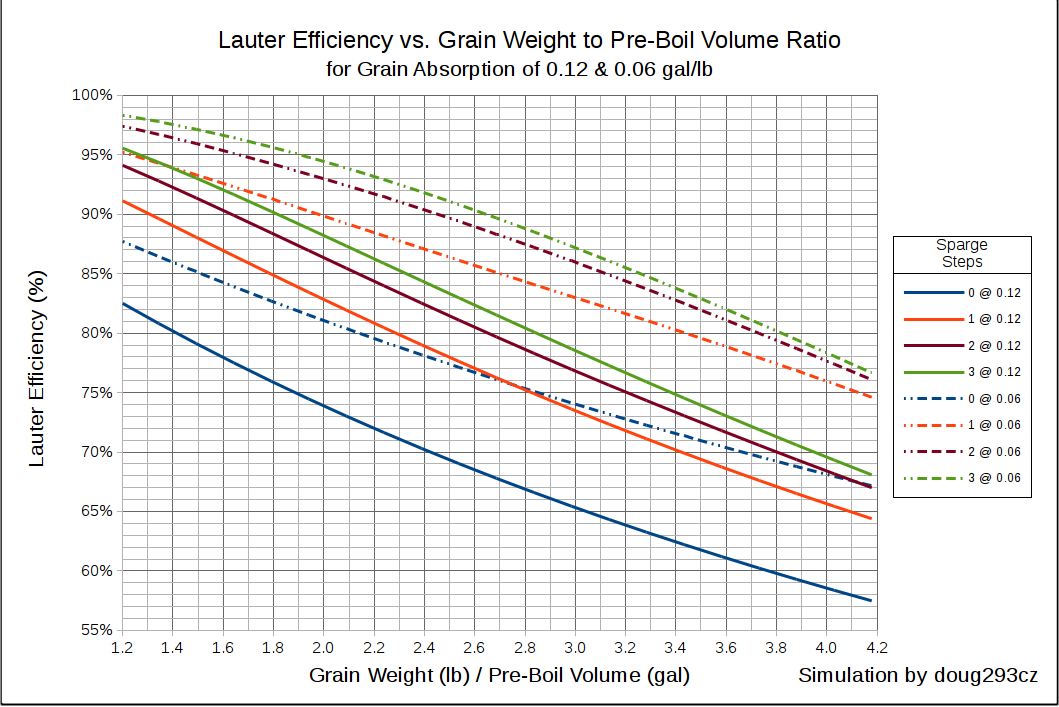

I'm thinking about converting to an all in one system. I do 5 gallon (finished beer) batches. And am wondering about volume of my system and whether or not I can get away with no sparge to keep my brew day as simple as possible.

So a few questions:

1) If you use an all in one system and do no sparge...

A) What size is your system (and batch size?)?

B) What efficiency are you getting?

C) Do you have any tips on improving your efficiency with no sparge?

2) If you have an all in one system and you sparge....

A) What is your preferred method to sparge?

B) What efficiency are you getting?

Thanks!

So a few questions:

1) If you use an all in one system and do no sparge...

A) What size is your system (and batch size?)?

B) What efficiency are you getting?

C) Do you have any tips on improving your efficiency with no sparge?

2) If you have an all in one system and you sparge....

A) What is your preferred method to sparge?

B) What efficiency are you getting?

Thanks!