I posted this for a couple of reasons:

1. To share my process with people who might learn from any of it

2. To get feedback and learn from the people here.

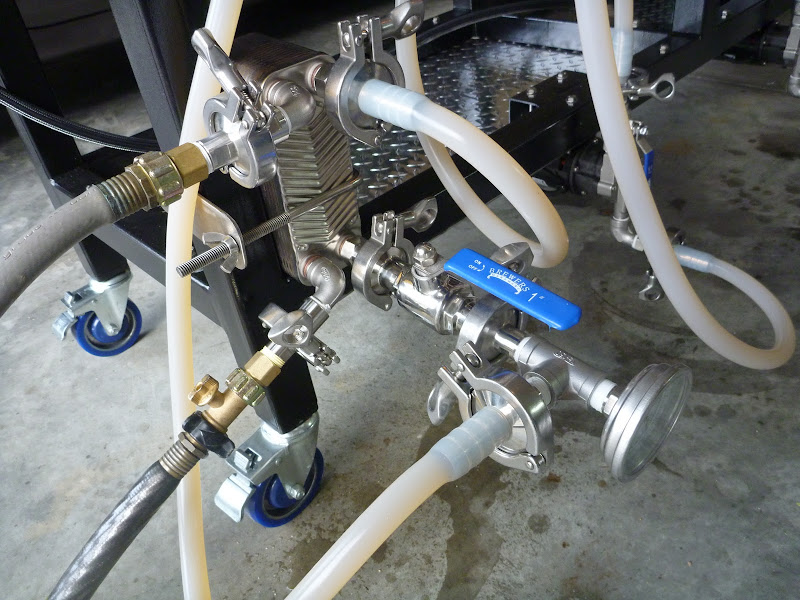

As a brewer you never spend enough money and time trying to improve what you do. On my last brewday I jotted down a lot of notes on what would make the next brew day better. I got feedback from a lot of great brewers, a few of which I focused on. Few of those was getting disconnects and using my pump to its fullest. I was planning to brew this weekend, tomorrow, and developed a recipe i thought i would like and have a yeast starter going. Tonight when i was setting up my Camlocks in my system, my mash tun ball valve snapped off. Very sad, wanted to make the best of it by redesigning my system. I have 2 converted kegs for my HLT and BK and a 10 gallon round cooler for my MLT.

I've outlined my new plans for the system, mainly for myself to visually see what I need to do and thought I would share, and at the same time get feedback from pro's who have done this before. Pic explains everything. Need to fix my mash tun and get the camlock system working nicely to brew asap as my starter is bubbling away since yesterday.

Cheers.

By aussiebrewerincolorado at 2012-01-14

1. To share my process with people who might learn from any of it

2. To get feedback and learn from the people here.

As a brewer you never spend enough money and time trying to improve what you do. On my last brewday I jotted down a lot of notes on what would make the next brew day better. I got feedback from a lot of great brewers, a few of which I focused on. Few of those was getting disconnects and using my pump to its fullest. I was planning to brew this weekend, tomorrow, and developed a recipe i thought i would like and have a yeast starter going. Tonight when i was setting up my Camlocks in my system, my mash tun ball valve snapped off. Very sad, wanted to make the best of it by redesigning my system. I have 2 converted kegs for my HLT and BK and a 10 gallon round cooler for my MLT.

I've outlined my new plans for the system, mainly for myself to visually see what I need to do and thought I would share, and at the same time get feedback from pro's who have done this before. Pic explains everything. Need to fix my mash tun and get the camlock system working nicely to brew asap as my starter is bubbling away since yesterday.

Cheers.

By aussiebrewerincolorado at 2012-01-14