I wanted to collect the opinions that can be found about fermentation temperature. There are tidbits around the forum but none seemed to be in one place. Below my post are quotes from users that I thought were helpful, feel free to skip down to them and read what they have to say.

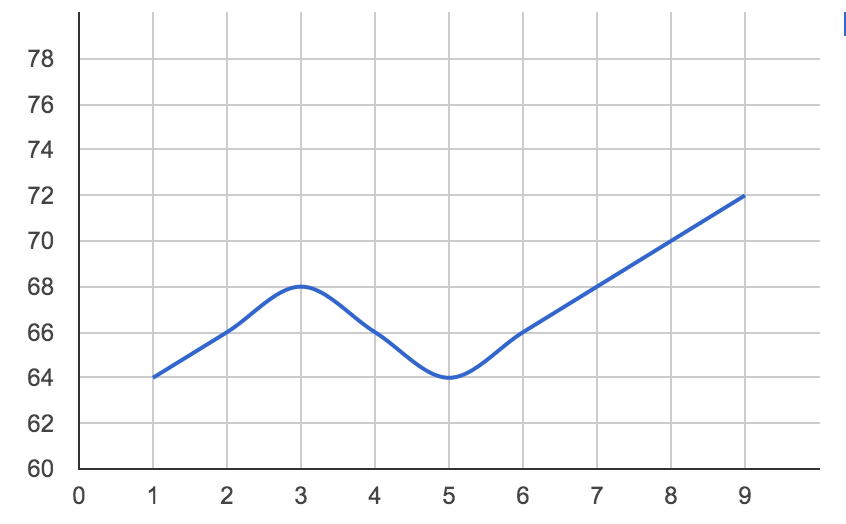

Most seem to agree on this forum that starting a few degrees below the yeasts recommended range produces the most predictably clean beers. WLP001 is a fairly popular yeast that benefits from starting around 64°F. The temperature range for it is 68 - 73°F. When you pitch the yeast your wort should be 64°F and your temperature controller should be set to that temperature for the next 3-4 days. You can certainly leave the temperature there for the duration of primary but it can benefit from ramping up the temperature towards the top of the yeasts range around the half to three-quarters mark along in your primary.

Does this seem correct? Would anybody recommend fermenting US-05 starting at 57°F? I am curious how people allow the temperature to rise under temperature control. I ferment in Phoenix, AZ where room temperature is often 80°F so letting it rise without the controller could cause problems.

Common yeast ranges:

US-05 = 59 - 71.6°F

US-04 = 59 - 68°F

WLP001 = 68 - 73°F

WLP002 = 65 - 68°F

WY1056 = 60-72F

This thread assumes you have a way to control your fermentation temperature using a digital controller with a thermometer attached to the side of your fermenter (temp differential set to .5°F). Most people seem to agree that you need to use a small piece of insulation over the thermometer helping it read the fermenters temperature. This thread also assumes you know how to properly pitch the correct amount of yeast for the batch you are inoculating. If you are underpitching you may want to pitch at a warmer temp than is indicated here. And finally, this thread is discussing Ales, Lagers are a whole different beast.

Most seem to agree on this forum that starting a few degrees below the yeasts recommended range produces the most predictably clean beers. WLP001 is a fairly popular yeast that benefits from starting around 64°F. The temperature range for it is 68 - 73°F. When you pitch the yeast your wort should be 64°F and your temperature controller should be set to that temperature for the next 3-4 days. You can certainly leave the temperature there for the duration of primary but it can benefit from ramping up the temperature towards the top of the yeasts range around the half to three-quarters mark along in your primary.

Does this seem correct? Would anybody recommend fermenting US-05 starting at 57°F? I am curious how people allow the temperature to rise under temperature control. I ferment in Phoenix, AZ where room temperature is often 80°F so letting it rise without the controller could cause problems.

Common yeast ranges:

US-05 = 59 - 71.6°F

US-04 = 59 - 68°F

WLP001 = 68 - 73°F

WLP002 = 65 - 68°F

WY1056 = 60-72F

Consider that yeast is a living organism, and you should be pitching active healthy yeast in the wort, in the proper amount. Yeast love being warmed, but don't like being cooled so pitching warm and then cooling can be easier but it's not best practice for the best healthy yeast. In general, it's best to pitch the proper amount of yeast at a temperature slightly lower than the desired fermentation temperature, and allow the temperature to rise. For example, I have an ale that I wish to ferment at 65 degrees. I will chill the wort to 62 degrees, and pitch 60 degree yeast slurry (or temper the yeast if using rehydrated dry yeast) into that. It will then rise to the temperature I want, and ferment well there. Raising the temperature at the tail end of fermentation encourages the yeast to fully attenuate and to clean up by products like diacetyl, if you can do that. Even just 3 degrees will encourage that process.

I start at the lower end (say 65°F) and each week raise it two degrees, final being 69°F.

I agree, never pitch warm. Even the Belgian brewers pitch the warm-fermented beers in the 60's and let them rise. It seems to me it is best to grow the crop of yeast on the cool side (first few days of fermentation) then after that you can alter the temps without undesired effects.

Pitch cool, raise temp to the high end of the yeast range when fermentation slows. You might dry it out a few points doing that. I have a heater on a separate temp control to do this.

A hot fermentation generates more heat than a cooler fermentation and controlling the temp down becomes more difficult. Starting low and rising to desired temp is a smoother and easier process.

I've made my best beers by starting at or slightly below my target temperature. Then, once the beer has been fermenting for a while (I think the ideal is when the beer is ~50% through), I ramp up the temp to ~65-70F. I do this for lagers and ales and then leave it at the warmer temp until fermentation signs have ceased. I then wait two more days and then rack it into the keg.

I have my temp probe between the carboy/bucket and a piece of styrafoam or cardboard depending on the vessel. I have taken many readings and have found the temp inside is 2-3*F higher than the probe on the outside and adjust the thermostat accordingly.

All three of these things(yeast pitch rate, ferment temp, oxygenation rate) are important for achieving a desired flavor profile for a German hefe.

I'd say that pitching at your normal temperature and then just letting it free rise would be a good experiment to run. I've only ramped my hefes up after 3 or 4 days, when the flavor profile has been largely determined. Waiting to ramp after 48 hours will most likely have little effect on the flavor profile.