OkieNotFromMuskogee

Active Member

Current Progress (will update as I go)

Ready for it's first batch!

Overview

I'm a bit new to microcontrollers and Raspberry Pi's so I wanted to post a build log that contains useful links, some issues I ran into, and resolutions. Hopefully it will help someone else, and be a reference for myself if I run into these issues again at some point.

Huge thank you to @LBussy for brewpi remix, and for the excellent documentation. Also the original creators of brewpi for making and keeping it open source. Check out their store http://www.brewpi.com

Goals

Parts

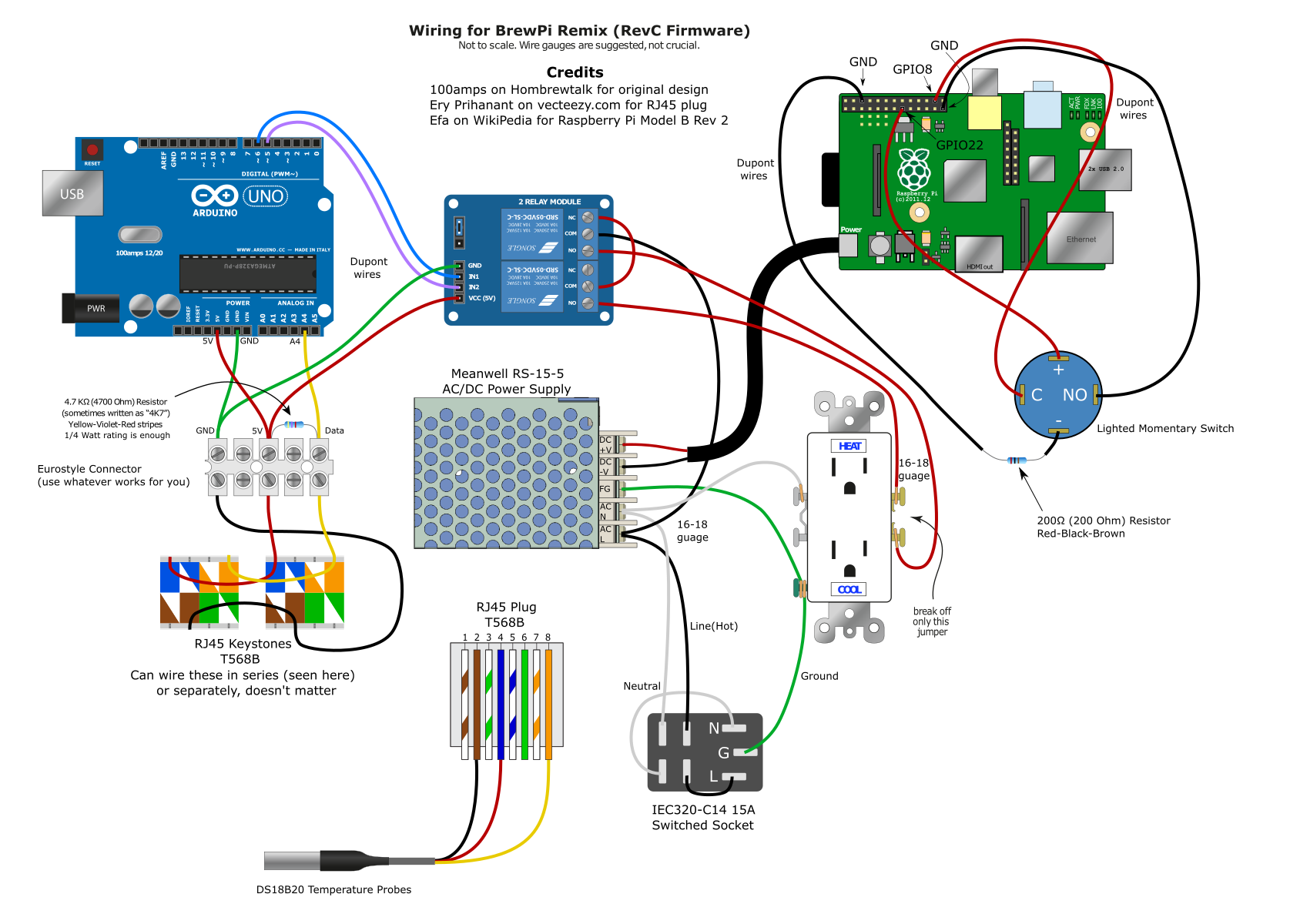

Below is an illustration of my wiring. A big thanks to @100amps for being kind enough to share some of the work he's done so I could use it. I will make one clarification on powering the Raspberry Pi from the AC/DC power supply. I chose to cut a USB cable and strip the wires down, and pwered it that way, as opposed to using the GPIO pins. I did this so the RPI is protected from over voltage and current spikes. Now with the power supply I used I don't belive that would be an issue, but I'd rather not have to yank out the RPI and replace it.

Approach

Test everything as you go, and take a break if you need to. This will save you time and headaches later, trust me. Things to test include:

Added two lines to /boot/config.txt

dtoverlay=gpio-shutdown,gpio_pin=8,active_low=0

gpio=22=op,dh

Issues Encountered

Enclosure: BrewPi Remix Enclosure by dufflebum

RJ45 Panel Mount: RJ45 Panel Mount for BrewPi Enclosure by dufflebum

Ready for it's first batch!

Overview

I'm a bit new to microcontrollers and Raspberry Pi's so I wanted to post a build log that contains useful links, some issues I ran into, and resolutions. Hopefully it will help someone else, and be a reference for myself if I run into these issues again at some point.

Huge thank you to @LBussy for brewpi remix, and for the excellent documentation. Also the original creators of brewpi for making and keeping it open source. Check out their store http://www.brewpi.com

Goals

- Use 1st gen Raspberry Pi rev B I had laying around

- Use power supply to power Raspberry Pi so only one plug/power cord is needed

- Use RJ45 connectors for the temp sensors since I already had connectors, keystones, and CAT5 cable laying around

- Initiate shutdown via button (LBussy's suggestion when running headless)

- No LCD display, possible OLED or eInk at a later time

- muhteeus build thread is a great starting point, and I used his wiring diagram and parst list to get me started.

- Brewpi Remix Thread

- The official brewpi remix page is also an excellent resource

- PDF of documentation, I prefer this to the online documentation because I like to scroll through and easily search for what I need

- Instructable on wiring a DS18B20 to an RJ45 connector

- Guide to Arduino and DS18B20 I used this to test my probes, which is a good idea if you're getting them from Amazon or Aliexpress

- LBussy's gist for shutting down a Raspberry Pi with an external button

Parts

- Raspberry Pi 1st gen Rev B

- USB WiFi Adapter (1st gen didn't have WiFi)

- 6 inch USB A to B Cable

- Elegoo Uno R3

- 2 - DS18B20 probes - I verified these are not parasitic only, and work well for this application

- 4.7kohm resistor (pack of resistors, can't really buy a single one)

- 600V 15A 3 position Screw Terminal

- SainSmart 2-Channel Relay

- 15a Outlet from Home Depot

- 6-32 nuts for attaching outlet

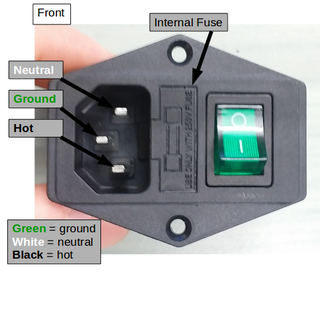

- 3 prong IEC 320 C14 socket with rocker - Edit: Updated link to a better one on DigiKey, don't get this off amazon, can burn down the house

- MEAN WELL RS-15-5 Power Supply - Don't cheap out here

- 2 - RJ45 Connectors

- 2 - RJ45 Keystones

- 2 - 3d printed RJ45 Keystone Panel Mounts

- Scrap CAT cable

- Optional - 3d printed project box

Below is an illustration of my wiring. A big thanks to @100amps for being kind enough to share some of the work he's done so I could use it. I will make one clarification on powering the Raspberry Pi from the AC/DC power supply. I chose to cut a USB cable and strip the wires down, and pwered it that way, as opposed to using the GPIO pins. I did this so the RPI is protected from over voltage and current spikes. Now with the power supply I used I don't belive that would be an issue, but I'd rather not have to yank out the RPI and replace it.

Approach

Test everything as you go, and take a break if you need to. This will save you time and headaches later, trust me. Things to test include:

- Testing all electrical connections with a multi-meter

- Testing individual components if their origin or reliability is in question (i.e. the temperature probes in my case)

Added two lines to /boot/config.txt

dtoverlay=gpio-shutdown,gpio_pin=8,active_low=0

gpio=22=op,dh

Issues Encountered

- Script not Running: This was just me being impatient, on a 1st gen Raspberry Pi it takes about 5 minutes after powering on the Pi for the script to start running.

- Flashing Arduino from web interface: This is on me, for two reasons. First I didn't connect the Arduino to the Raspberry Pi the first time I installed brewpi remix, I just wanted to see if it would even install on such and old board, which it did. Second, not reading the documentation where this is not recommended at all. I got a variety of errors, including fatal serial error. I resolved this by flashing it via the command line: sudo /home/brewpi/utils/updateFirmware.py

- Flashing the wrong shield: Unfortunately neither brewpi remix install webpage, or the FAQ talks about which shield to choose. However the documentation (which I failed to read at first) does. So I flashed the IC2 shield, which I do not have. Fortunately the documentation also explains how to change shields when flashing from the command line: sudo /home/brewpi/utils/updateFirmware.py --shield

- Saving devices didn't actually save them in Device Configuration: Again thank god for the documentation, where this is specifically addressed. Just reprogramed the controller (arduino) using the command line sudo /home/brewpi/utils/updateFirmware.py and select to not reload settings and devices

- Finding a correct pinout for my old Raspberry Pi: Being new to Raspberry Pi's I didn't know you could just open a terminal and type pinout, once I discovered this, my life was a lot easier.

- After wiring in the RJ45 Keystones, one of the temp sensors wasn't reading in the BrewPi Remix Device Configuration: First I plugged one in at a time to find one I knew was working, then I plugged the other temp sensor into the same RJ45 keystone, and it worked, so I knew both the temp sensors were working, so it must be one of the keystones. I double checked my punchdown, and I had a wire in the wrong spot (Brown wire in the Brown-White spot). Moved it to the correct spot and it started working.

Enclosure: BrewPi Remix Enclosure by dufflebum

RJ45 Panel Mount: RJ45 Panel Mount for BrewPi Enclosure by dufflebum

Last edited: