augiedoggy

Well-Known Member

I hoping someone could answer a question I cannot seem to get an answer for from google.

I have a large 3bbl brewing panel thats powered by 2 60a separate power feeds (they remain separate in the panel)

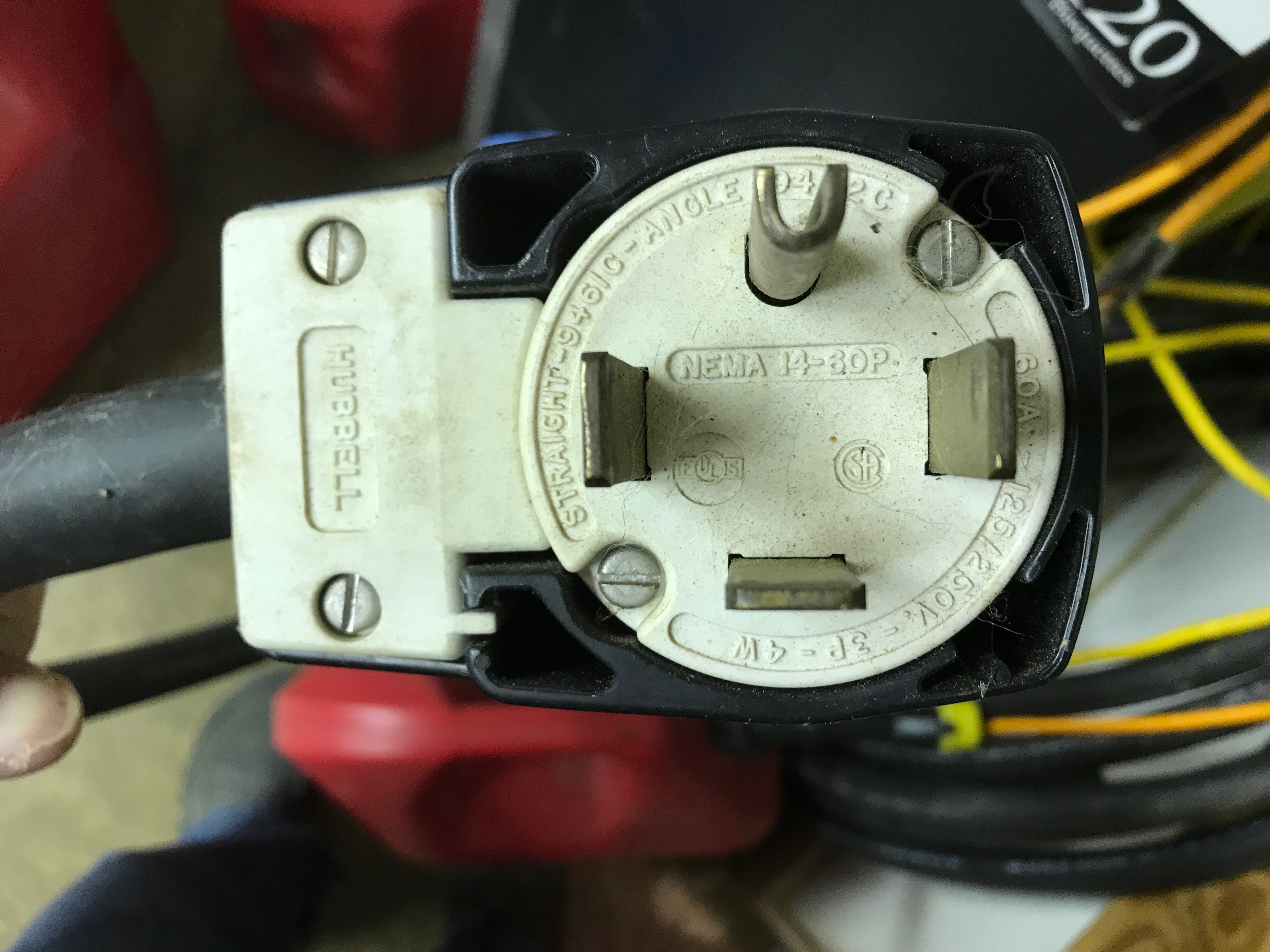

I am having two 60a gfci outlets put in to plug the panel in rather than hard wiring and Im having a hard time finding out if a "3 phase" nema 15-60r plug and outlet can be used in a single phase configuration and still pass code...

For that matter I am having a hard time finding a single phase 60a nema configuration?

The prices seem to go astronomical for 60a vs 50a.

thanks.

PS also can I use 12/3 SO or SJ wiring for 240v (no neutral) power to my 240v 2000w rims outlet if I color code the white wire to red at both ends or is this something that would be up to the local code inspector?

I have a large 3bbl brewing panel thats powered by 2 60a separate power feeds (they remain separate in the panel)

I am having two 60a gfci outlets put in to plug the panel in rather than hard wiring and Im having a hard time finding out if a "3 phase" nema 15-60r plug and outlet can be used in a single phase configuration and still pass code...

For that matter I am having a hard time finding a single phase 60a nema configuration?

The prices seem to go astronomical for 60a vs 50a.

thanks.

PS also can I use 12/3 SO or SJ wiring for 240v (no neutral) power to my 240v 2000w rims outlet if I color code the white wire to red at both ends or is this something that would be up to the local code inspector?