BeardedBrews

Well-Known Member

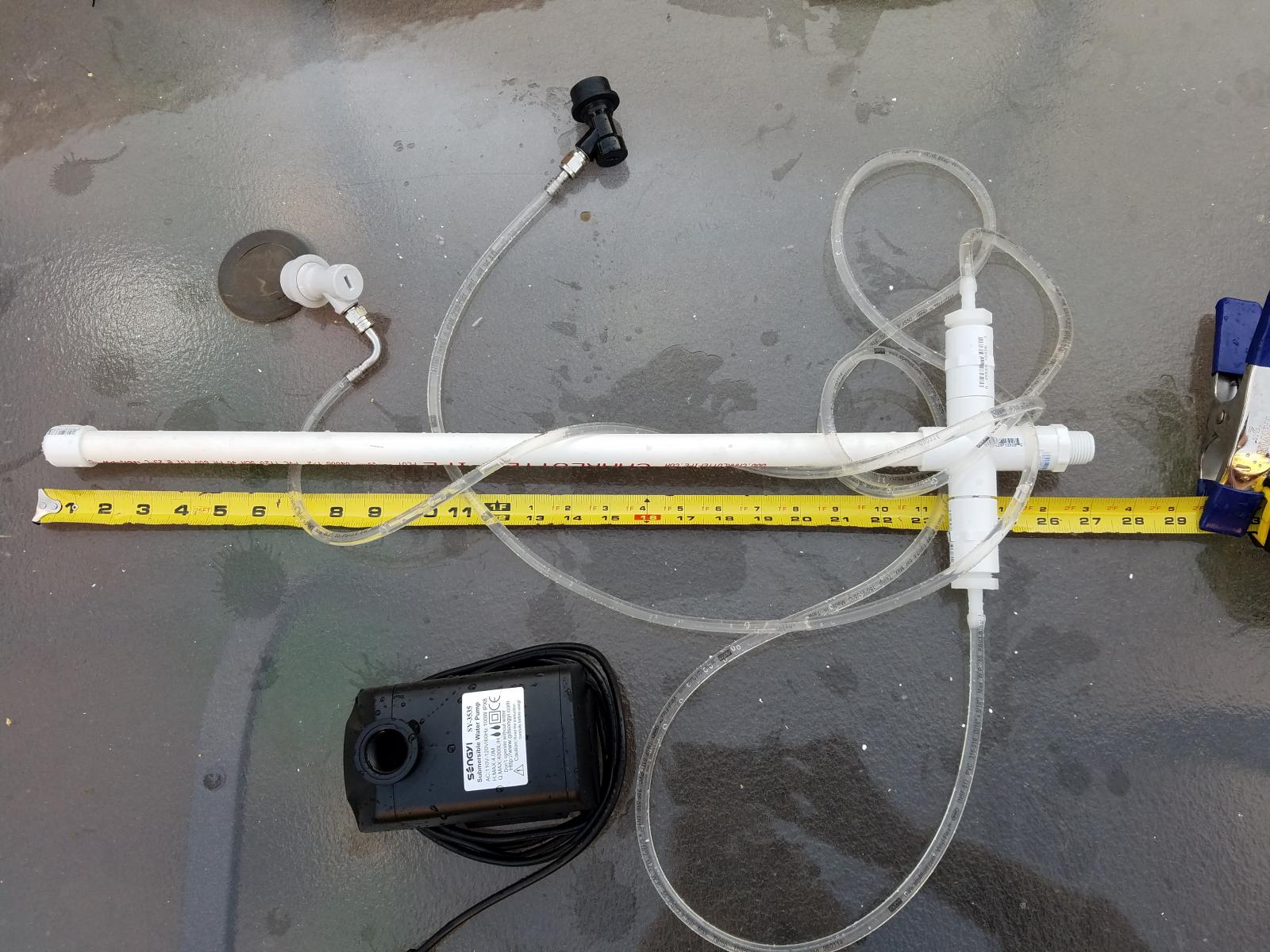

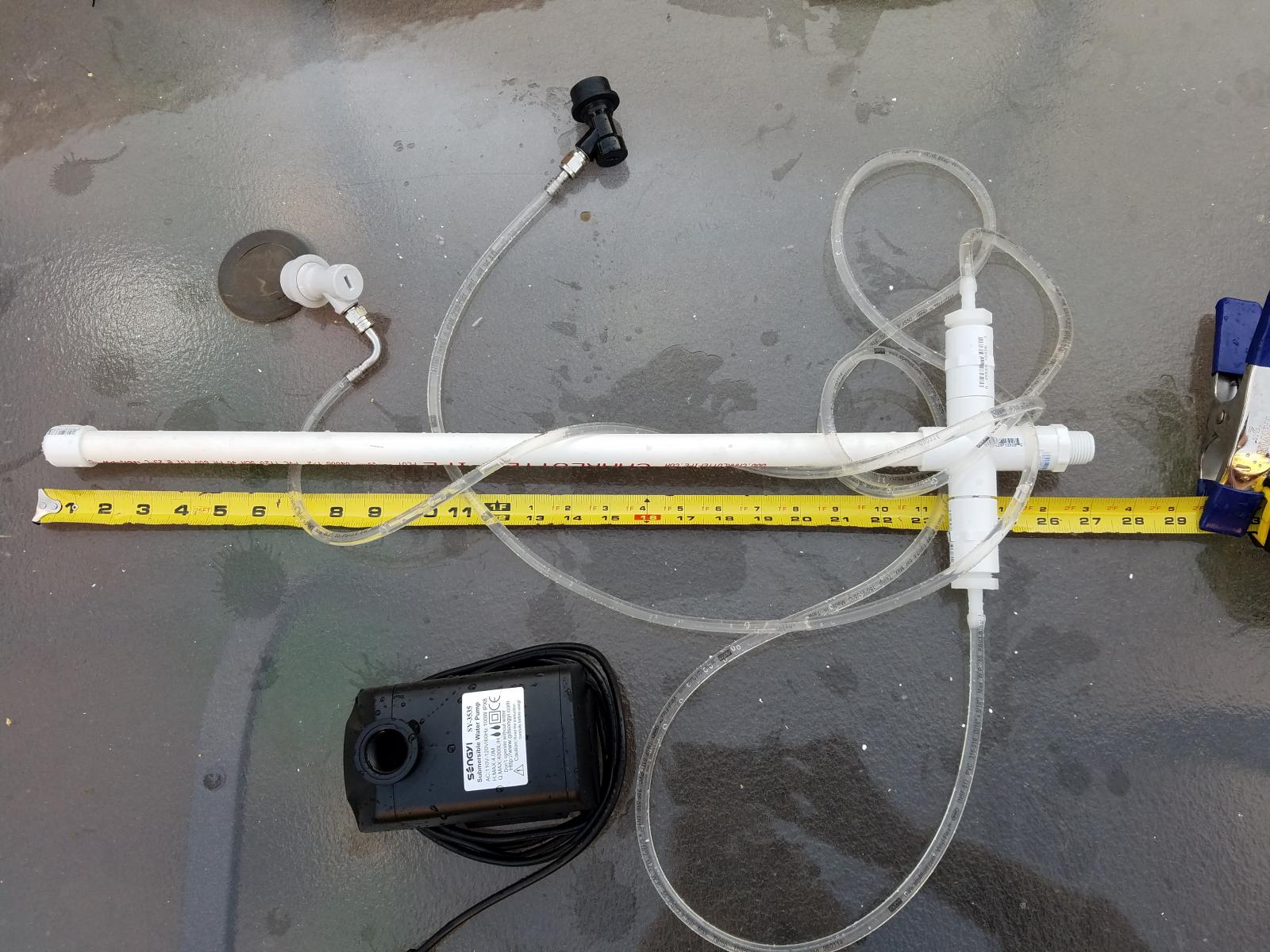

OK... let's get right to the point:

This 880gpm pump is $25 on prime and the outlet is a standard 1/2" thread.

https://www.amazon.com/dp/B01CGAD986/?tag=skimlinks_replacement-20

Everything else in this post is just a simplified version of the work other people on hbt have done. I just took the easiest from all the other posts.

I spent $8 at Lowe's for a 4' stick of 1/2 pvc, a 1/2 male thread to slip, a slip tee, a 1/2 cap, two 1/2 slip to female 1/2 thread, and two 1/2 male thread to 1/4 hose barb.

I also included 10' of 3/16 id vinyl that I had in the garage and a set of ball lock connectors. I had a carboy drying plastic thing and some pieces of wood. These add cost, you should have them already, if not, +$15.

But can it shoot???

Yes. With the ball lock lines off (worst case for pressure) it shoots 5-6' up and 12-14' out.

Complete coverage in a carboy. Almost more flow than can drain.

It has way more flow/pressure than would be needed to drive my MalFet bottle washer. Probably 3x.

It ships with a hose barb that you can poke into 1/2 ID silicone tubing, which also fits over your taps. Automatic beer line cleaner.

"But Bro! Does it even work with cam locks??" YES.

How do I make it?

Pics attached.

No Glue??

Nope.

Enjoy.

This 880gpm pump is $25 on prime and the outlet is a standard 1/2" thread.

https://www.amazon.com/dp/B01CGAD986/?tag=skimlinks_replacement-20

Everything else in this post is just a simplified version of the work other people on hbt have done. I just took the easiest from all the other posts.

I spent $8 at Lowe's for a 4' stick of 1/2 pvc, a 1/2 male thread to slip, a slip tee, a 1/2 cap, two 1/2 slip to female 1/2 thread, and two 1/2 male thread to 1/4 hose barb.

I also included 10' of 3/16 id vinyl that I had in the garage and a set of ball lock connectors. I had a carboy drying plastic thing and some pieces of wood. These add cost, you should have them already, if not, +$15.

But can it shoot???

Yes. With the ball lock lines off (worst case for pressure) it shoots 5-6' up and 12-14' out.

Complete coverage in a carboy. Almost more flow than can drain.

It has way more flow/pressure than would be needed to drive my MalFet bottle washer. Probably 3x.

It ships with a hose barb that you can poke into 1/2 ID silicone tubing, which also fits over your taps. Automatic beer line cleaner.

"But Bro! Does it even work with cam locks??" YES.

How do I make it?

Pics attached.

No Glue??

Nope.

Enjoy.

Last edited by a moderator: