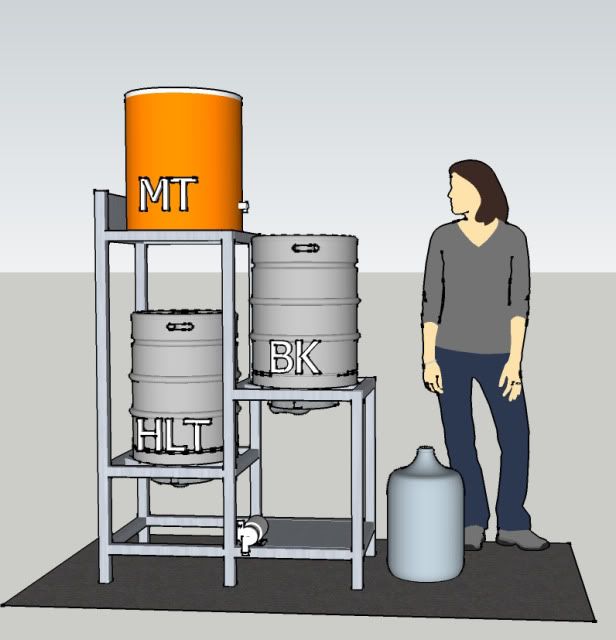

I am at the point where its starting to get necessary to build a brew rig to brew outdoors, and out of the kitchen. I ran into an old neighbor who is willing to trade some homebrew to build me a rig. I had designed a 2.5 tier brew stand, but am now left with some questions about how feasible it actually is.

I call it a 2.5 tier because I found a design by someone else similar to this, and that's what they referred to it as. Its not quite a 3 tier because there is a pump involved, and its definitely not a 2 tier as you can see. Trying to create as small as a stand as possible to save space.

Will the march pump pump water approximately 5' high? Does anybody see any issues other than the pump maybe not being sufficient to raise the water that height?

It will be propane fired, with 2 banjo burners under the HLT and the Brew Kettle. Gravity fed from the Mash Tun to the Carboy. Will most likely cool with a CFC.

Any help / input is greatly appreciated!

I call it a 2.5 tier because I found a design by someone else similar to this, and that's what they referred to it as. Its not quite a 3 tier because there is a pump involved, and its definitely not a 2 tier as you can see. Trying to create as small as a stand as possible to save space.

Will the march pump pump water approximately 5' high? Does anybody see any issues other than the pump maybe not being sufficient to raise the water that height?

It will be propane fired, with 2 banjo burners under the HLT and the Brew Kettle. Gravity fed from the Mash Tun to the Carboy. Will most likely cool with a CFC.

Any help / input is greatly appreciated!