Loyd

Well-Known Member

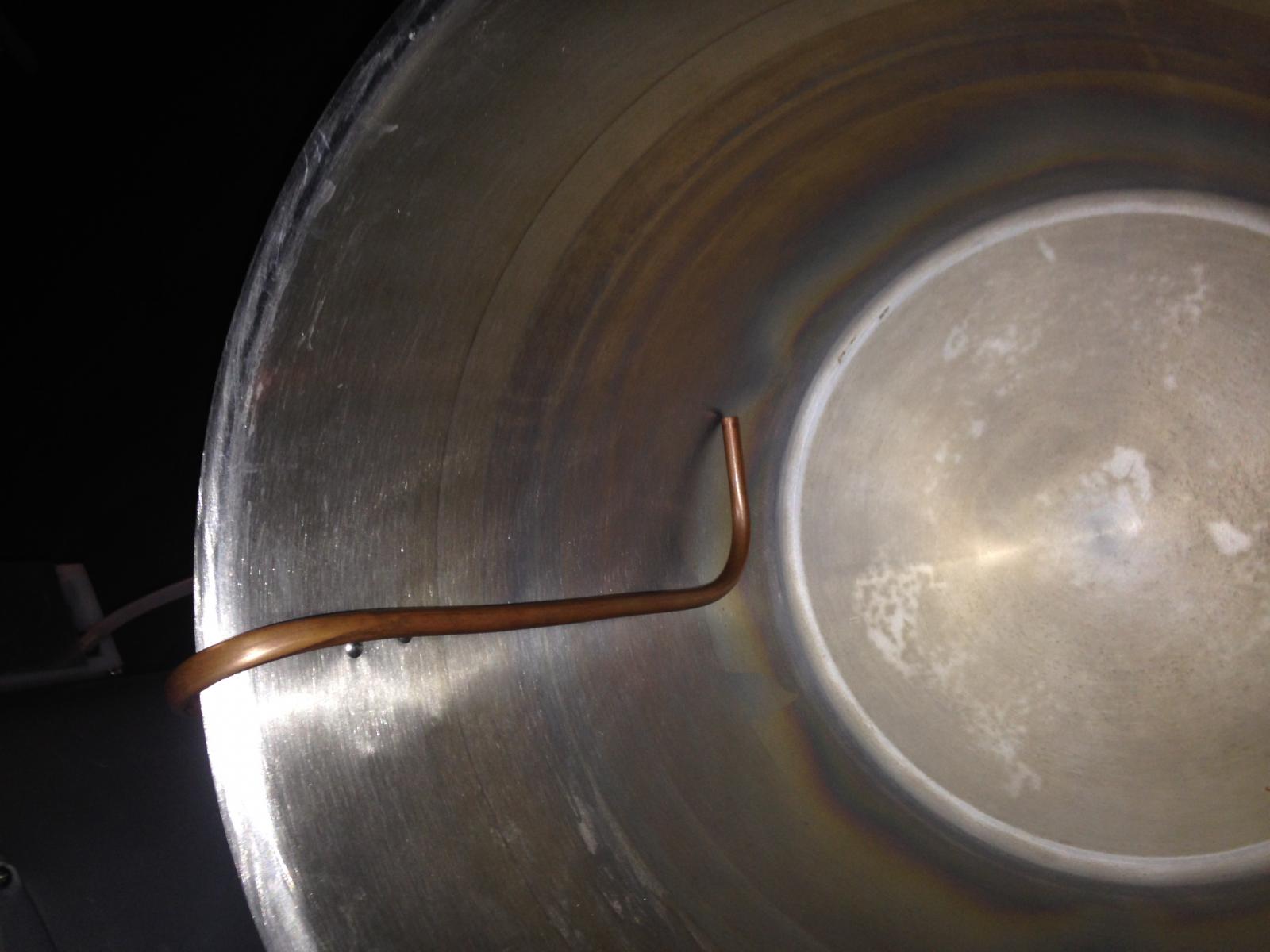

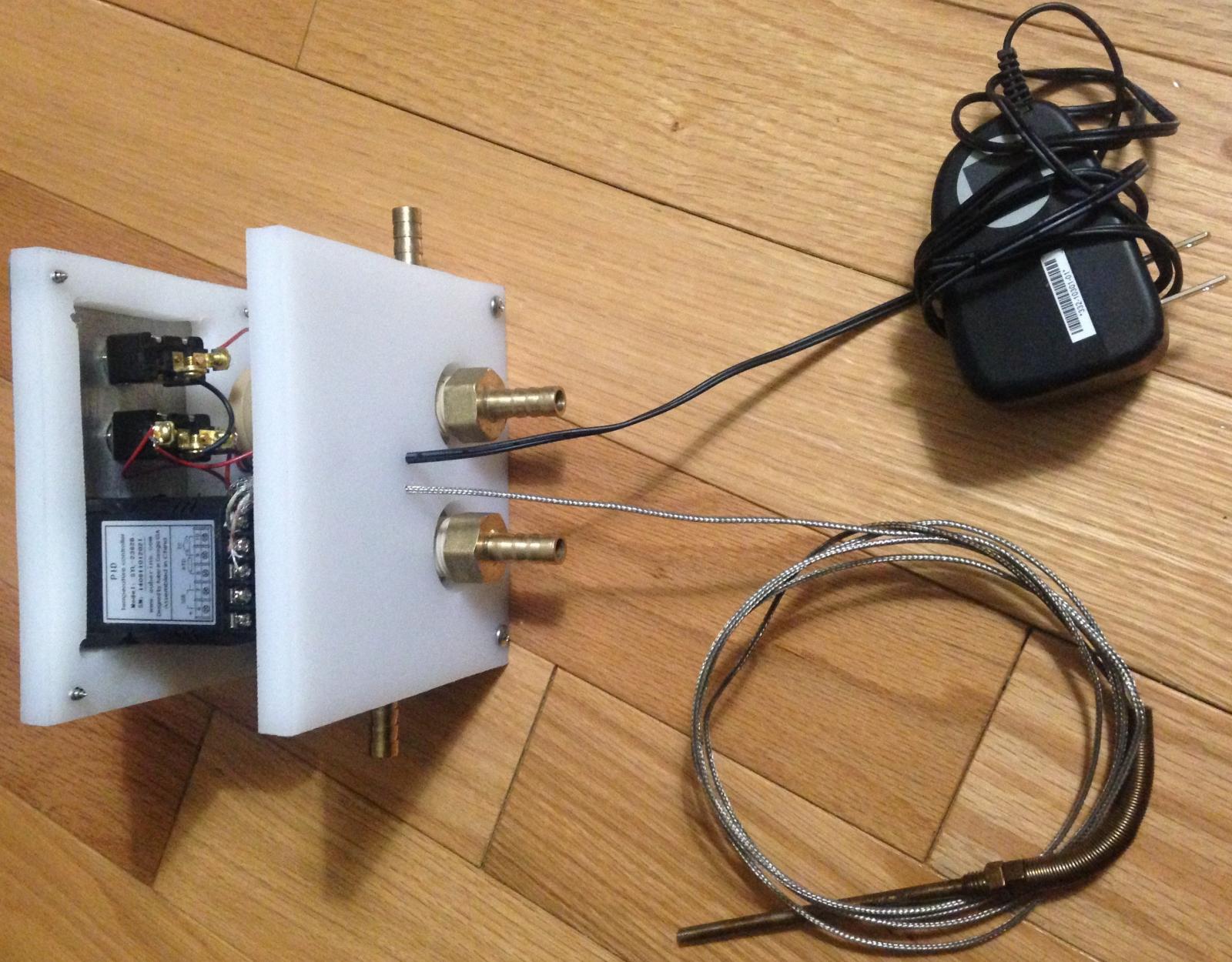

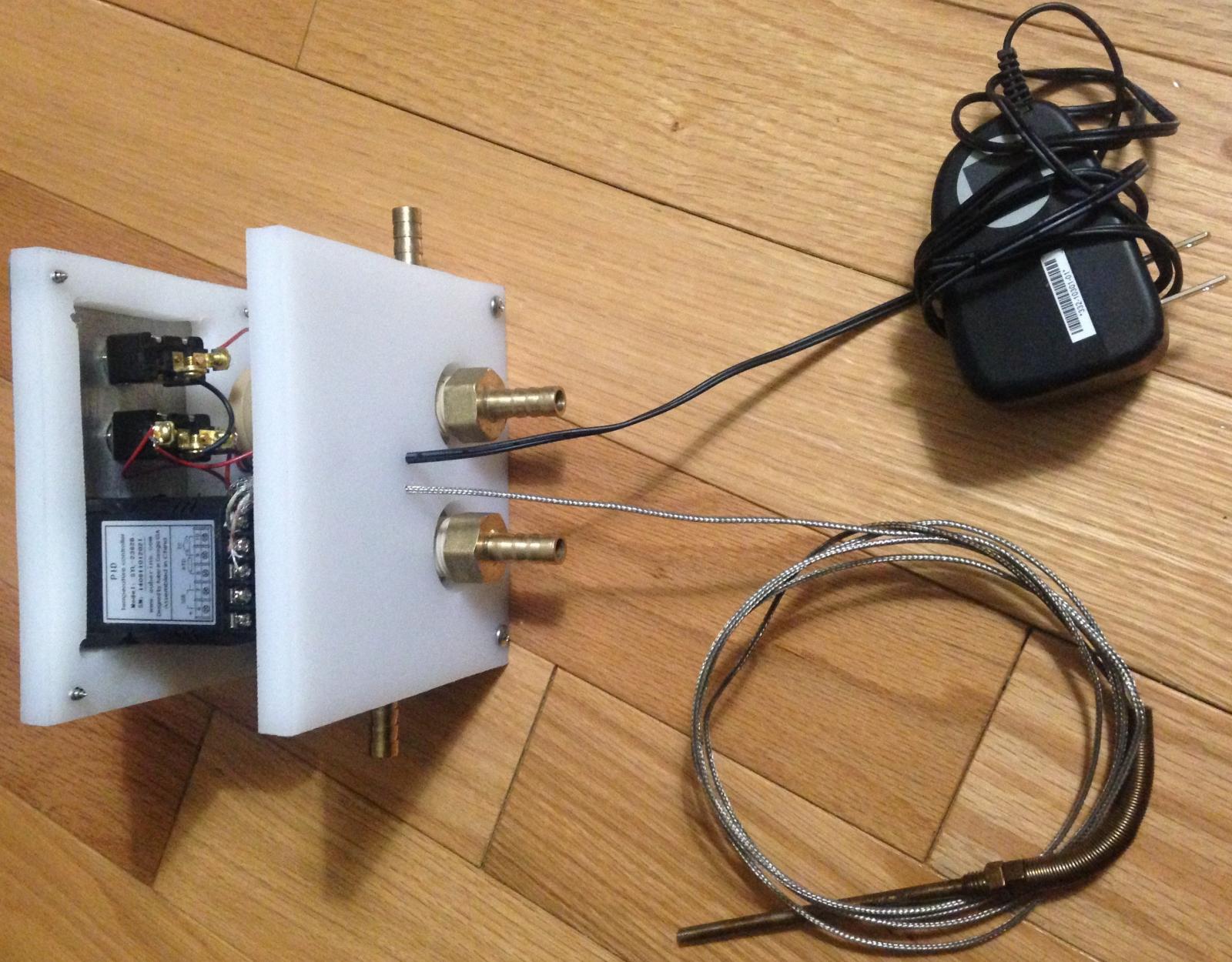

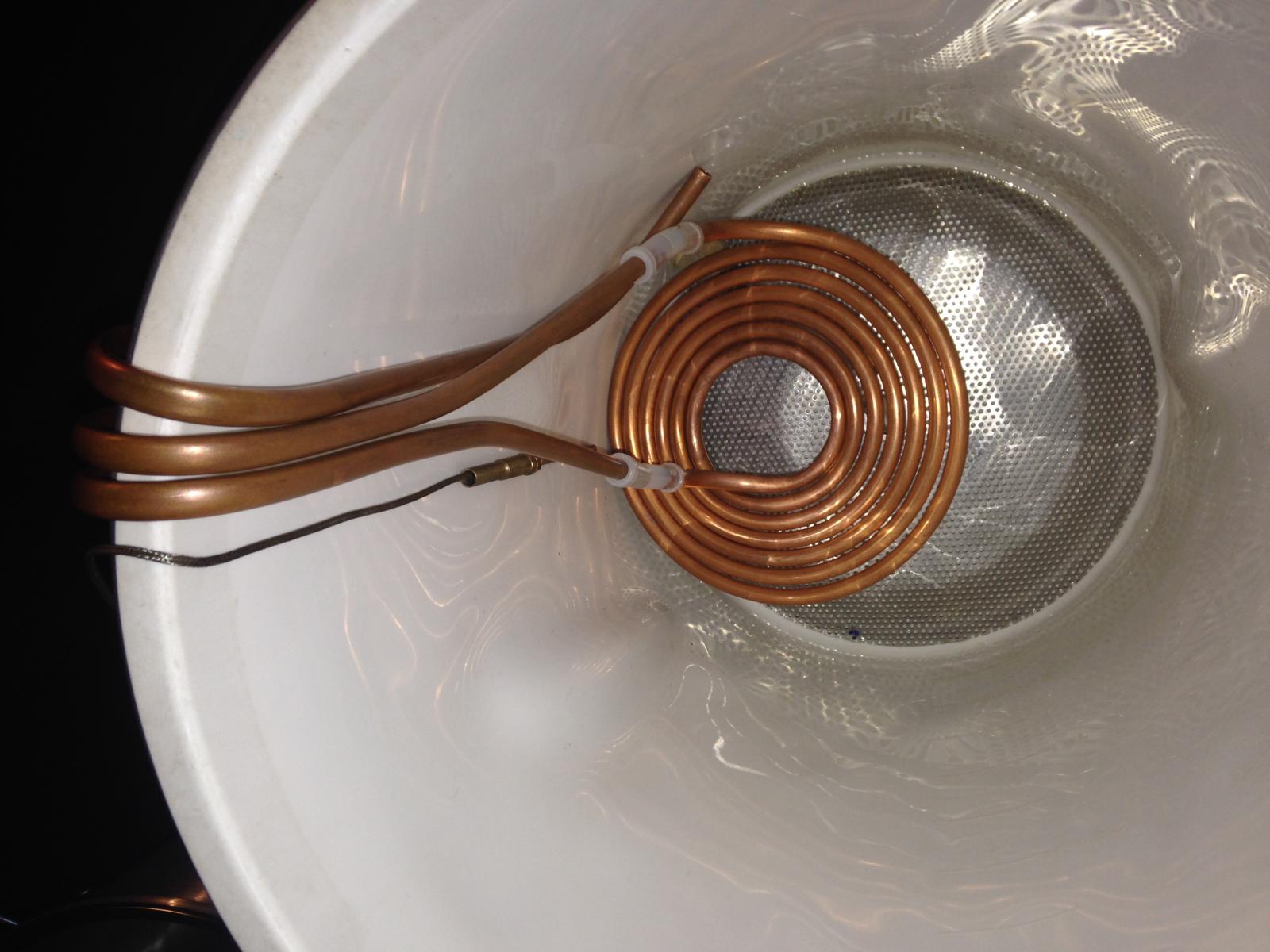

This is what I came up with based on parts I had laying around from other projects. It uses two of the ChiCom Solar water pumps, an Auberins PID controller set to on/off, about 10' of silicone tubing, about 15' of 3/8 copper tubing and a couple 3/8" barbed fittings.

After researching the Definition of HERMS I think this system would actually be a HERWS Heat Exchanger Recirculating Water System.

After researching the Definition of HERMS I think this system would actually be a HERWS Heat Exchanger Recirculating Water System.

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)