spaceyaquarius

Well-Known Member

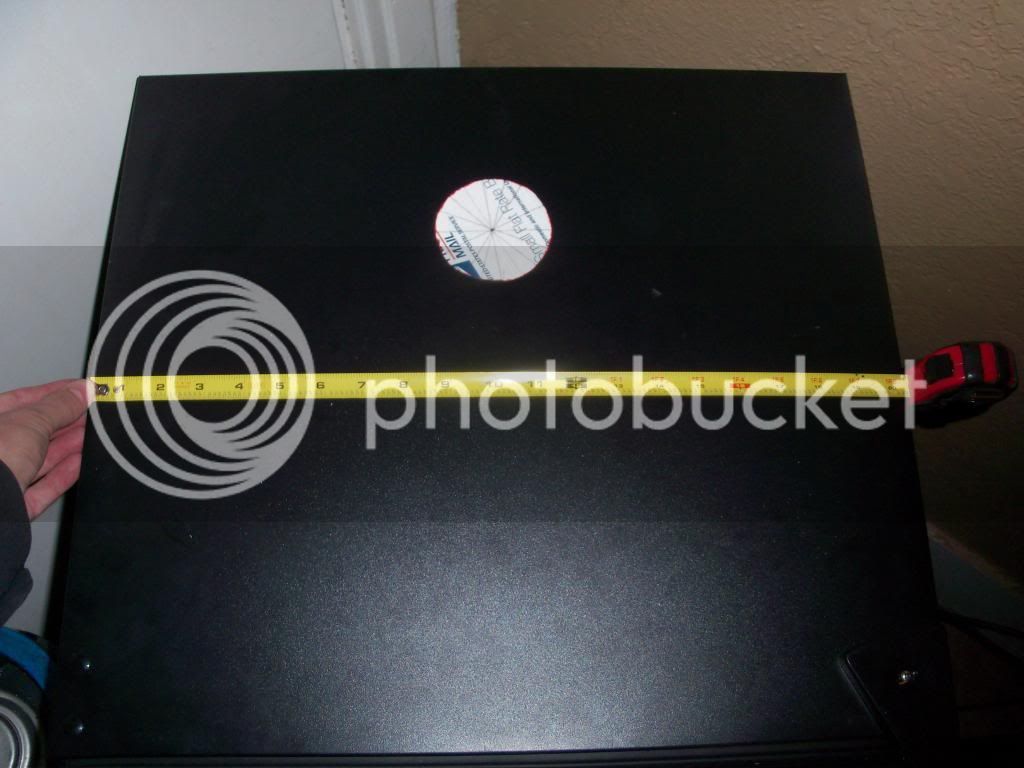

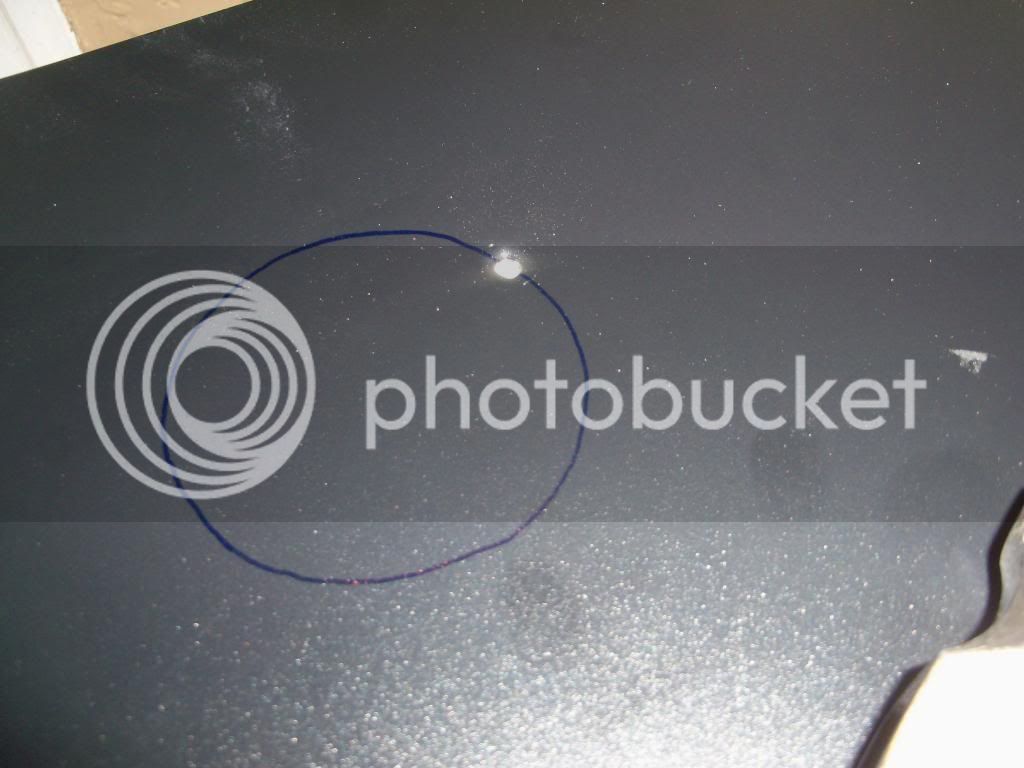

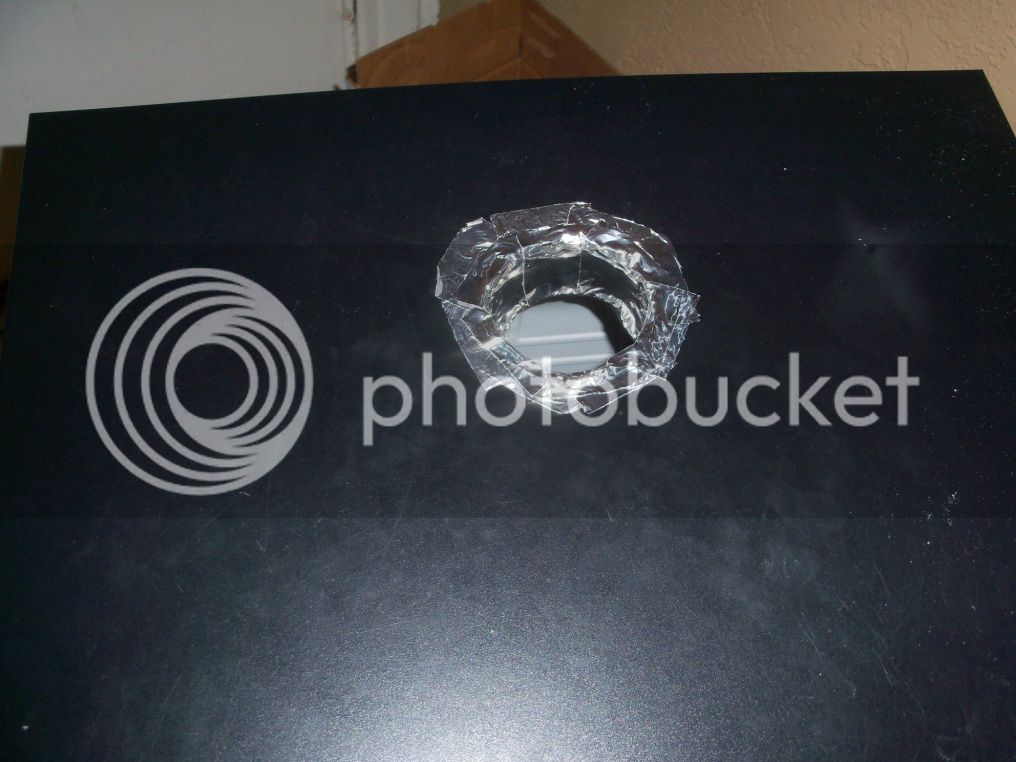

I accidentally ordered this Danby model# DCR122BLDD 4.3 cubic foot mini-fridge when I was trying to order the Danby model # 440BL 4.4 cubic foot mini-frdige (which I have already converted into a kegerator).

Below is the link for my step by step Danby model 440BL kegerator conversion:

https://www.homebrewtalk.com/f51/danby-dar440bl-mini-fridge-conversion-kegerator-453105/

You can convert this model into a kegerator, and it is $50-$150 cheaper than the Danby 440BL. For some reason, the 440BL price ranges from $115-$300, I got the DCR122BLDD for $115 + free shipping with Amazon. The 440BL is easier, so if you can find it at a good price, pick the 440BL.

Ok, you have the DCR122BLDD for some reason.

Equipment Required:

• One Danby brand 4.4 inner cubic feet, model number DAR440BL mini-fridge = $200

• Two 5-gallon Cornelius kegs outer aluminum and inner stainless steel = $120-$180

• Double-tap stainless steel draft tower 3” ID w/Perlick 525SS faucets = $100-$120

• Vice grips/box knife/hammer/allen wrench/electrical tape/wire cutter = $25

• New CO2 tank (filled) = $90-$100 (with refills at $10-$20 each)

• Four MFL ball lock quick-connects w/3/16" male barbs = $32

• Two sets of 10 ft., ¾” inner diameter lines = $22

• Double CO2 regulator + plumbers tape = $100

• Drip tray for the top of the fridge = $40

• Progressively larger screws/ nails = $5

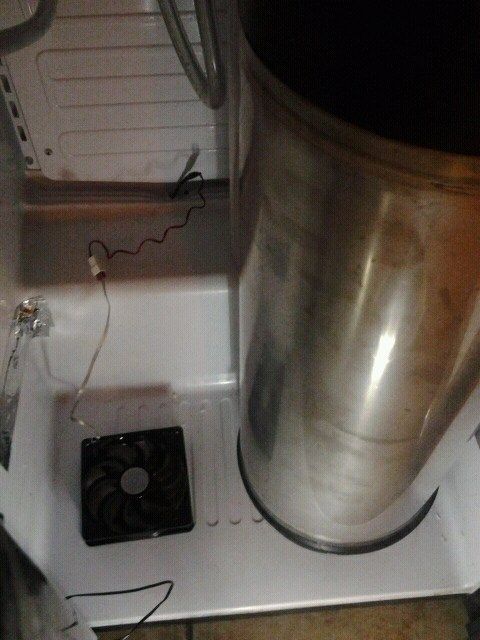

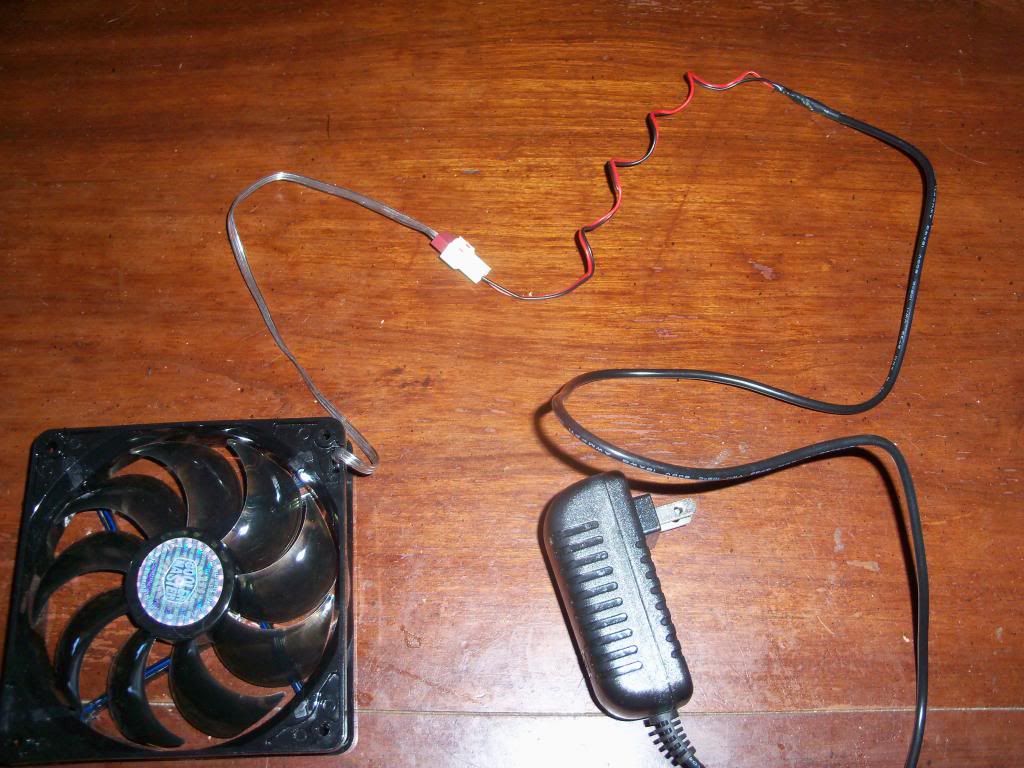

• PC fan with cool blue lighting = $15

• Two 5/16" ID vinyl gas lines = $20

• Waterproof aluminum tape = $7

• Power converter AC/DC = $4

• Two male to male barbs = $6

• Four fender washers = $2

The main difference between the models is that the cheaper DCR122BLDD has a freezer compartment that has to be moved, and also that the side shelving has to be cut out with a box knife. The DCR122BLDD also has no inner light source, or drain hole that I could find, so instead of running a PC fan through it, you could just use the copper pipe method (or just run your PC fan wire out the door.

Below is the link for my step by step Danby model 440BL kegerator conversion:

https://www.homebrewtalk.com/f51/danby-dar440bl-mini-fridge-conversion-kegerator-453105/

You can convert this model into a kegerator, and it is $50-$150 cheaper than the Danby 440BL. For some reason, the 440BL price ranges from $115-$300, I got the DCR122BLDD for $115 + free shipping with Amazon. The 440BL is easier, so if you can find it at a good price, pick the 440BL.

Ok, you have the DCR122BLDD for some reason.

Equipment Required:

• One Danby brand 4.4 inner cubic feet, model number DAR440BL mini-fridge = $200

• Two 5-gallon Cornelius kegs outer aluminum and inner stainless steel = $120-$180

• Double-tap stainless steel draft tower 3” ID w/Perlick 525SS faucets = $100-$120

• Vice grips/box knife/hammer/allen wrench/electrical tape/wire cutter = $25

• New CO2 tank (filled) = $90-$100 (with refills at $10-$20 each)

• Four MFL ball lock quick-connects w/3/16" male barbs = $32

• Two sets of 10 ft., ¾” inner diameter lines = $22

• Double CO2 regulator + plumbers tape = $100

• Drip tray for the top of the fridge = $40

• Progressively larger screws/ nails = $5

• PC fan with cool blue lighting = $15

• Two 5/16" ID vinyl gas lines = $20

• Waterproof aluminum tape = $7

• Power converter AC/DC = $4

• Two male to male barbs = $6

• Four fender washers = $2

The main difference between the models is that the cheaper DCR122BLDD has a freezer compartment that has to be moved, and also that the side shelving has to be cut out with a box knife. The DCR122BLDD also has no inner light source, or drain hole that I could find, so instead of running a PC fan through it, you could just use the copper pipe method (or just run your PC fan wire out the door.