Hey all,

Quick perhaps easy question here, but I just gotta know.

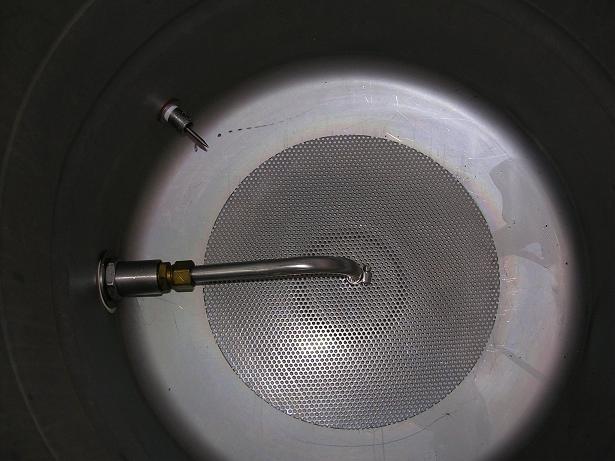

I have a 15.5 gal keg with top cut out that I would like to use to make the switch to all grain. Ball valve already tapped into the bottom, but even as low as it is, it is a couple inches above the bottom of the keg. If I used a stainless braid as a manifold to drain it, what do I do about the 1.5 gal or so at the bottom of the keg?

Will it siphon up and out the ball valve? Should I connect a piece of pipe and a 45 before I install the manifold? Other solutions that I haven't thought of?

Thanks for helping me along the path....

Quick perhaps easy question here, but I just gotta know.

I have a 15.5 gal keg with top cut out that I would like to use to make the switch to all grain. Ball valve already tapped into the bottom, but even as low as it is, it is a couple inches above the bottom of the keg. If I used a stainless braid as a manifold to drain it, what do I do about the 1.5 gal or so at the bottom of the keg?

Will it siphon up and out the ball valve? Should I connect a piece of pipe and a 45 before I install the manifold? Other solutions that I haven't thought of?

Thanks for helping me along the path....