Ok, so I get it that most of you on in this forum are experienced with electricity and are more interested in fancy panels and more elaborate systems.

I just want to brew in my basement in the winter in Michigan.

I'm willing to try and get my head wrapped around this because I have worked with a soldering iron before for modifications to microphones and other basic audio applications. AND because I have some friends who can help me out. They just are brewers. So I need help piecing things together.

I have the 15 gal Megapot 1.2

I add this: No Triclover, Weldless Only From brewhardware.com

AND this element:

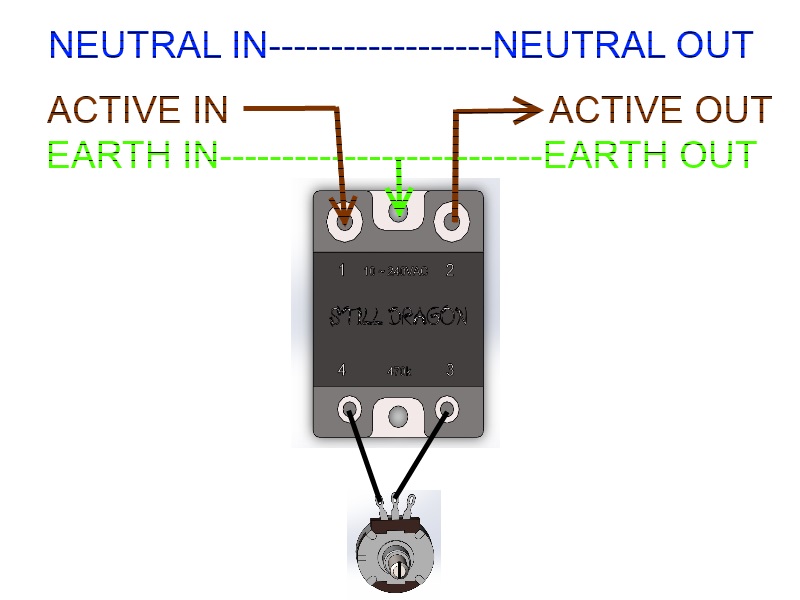

This controller

http://www.stilldragon.com/diy-controller.html

Then all I need is

*cable

*plug

*someone to wire up a 240 CFGI outlet in the basement?

Your help, suggestions...insight is much appreciated.

I just want to brew in my basement in the winter in Michigan.

I'm willing to try and get my head wrapped around this because I have worked with a soldering iron before for modifications to microphones and other basic audio applications. AND because I have some friends who can help me out. They just are brewers. So I need help piecing things together.

I have the 15 gal Megapot 1.2

I add this: No Triclover, Weldless Only From brewhardware.com

AND this element:

This controller

http://www.stilldragon.com/diy-controller.html

Then all I need is

*cable

*plug

*someone to wire up a 240 CFGI outlet in the basement?

Your help, suggestions...insight is much appreciated.