Attn: P-J, maybe you have done this before but I can not find it so…

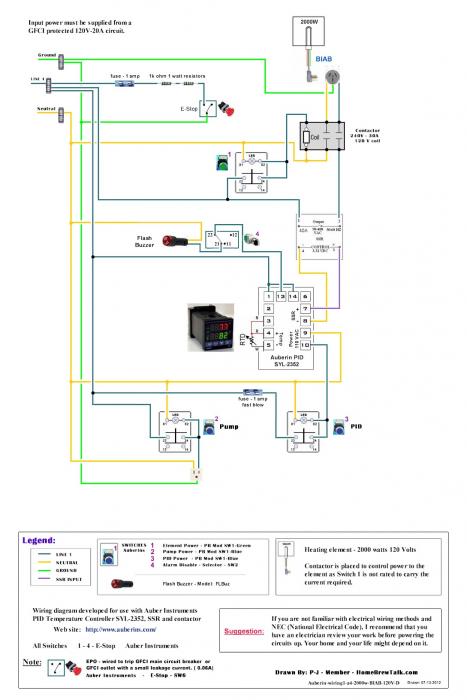

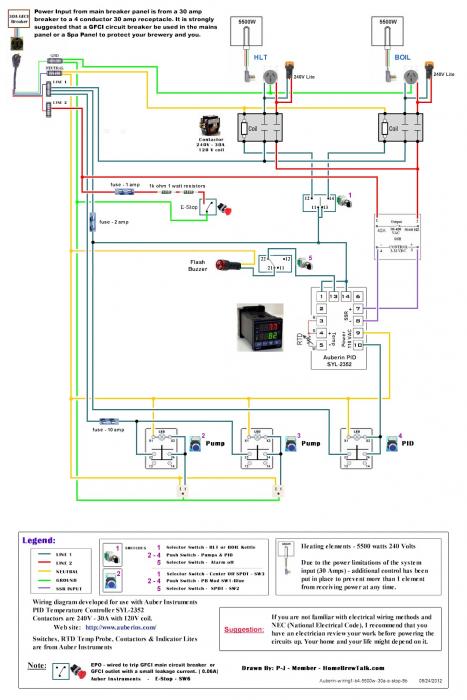

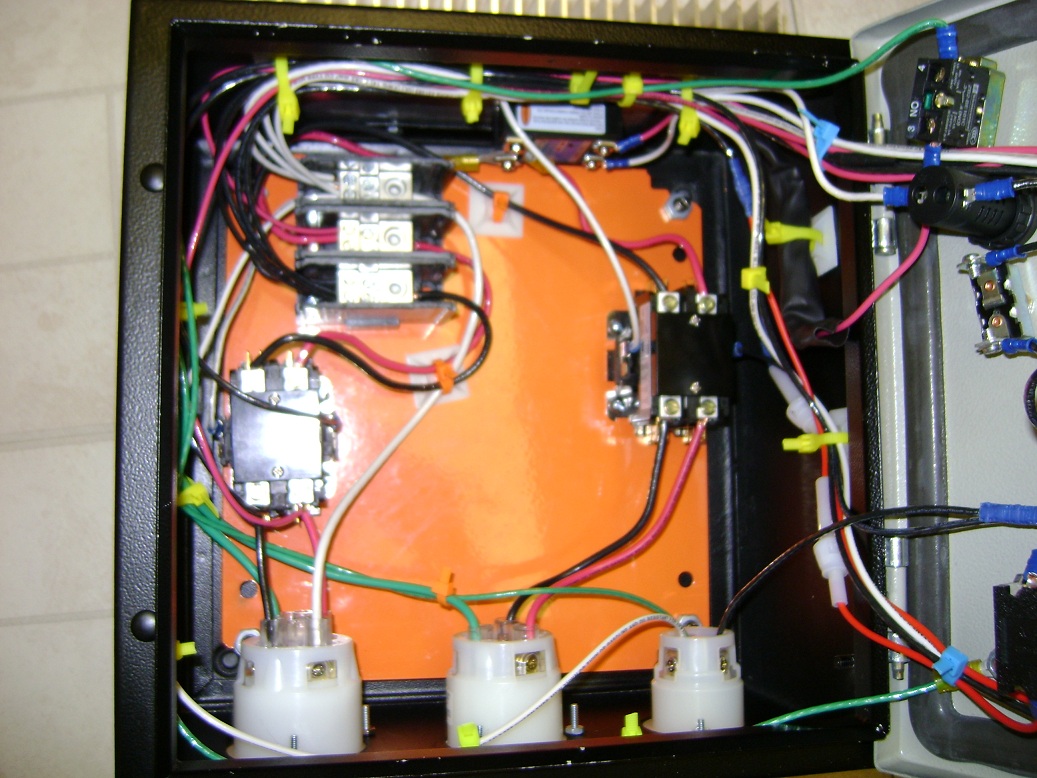

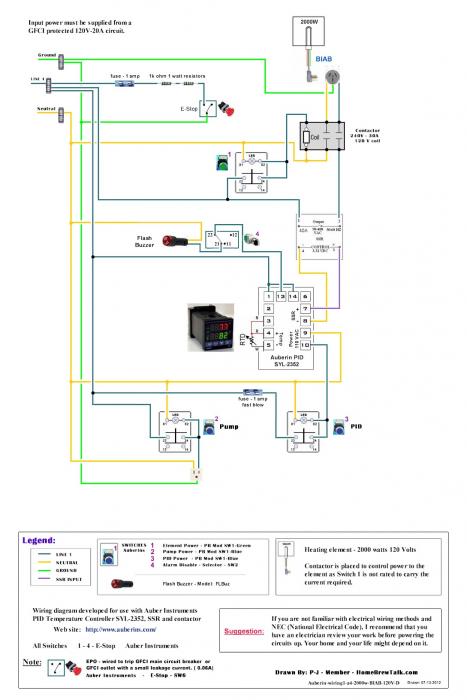

My current setup is a double keggle system, one for the hot liquor tank and one for the boil kettle, with a 10 gallon water cooler mash tun and a March pump. I have a single 2000w heating element in each keg, which has served me well so far but I would like finer control and to stop physically plugging elements in. My problem lies in that I currently have access to a single 20A circuit to brew off of. So this controller will need to control both elements, but only one at a time (i.e. the HLT OR the BK, no need to have both running). Further I don't really need the PID to control the BK, at least not automatically the temp probe will live in the HLT (it all ready has a thermowell). I really like the design of the following post.

I would like something very similar but with the option of choosing which element is on and an indicator light to remind me which one is. I was thinking a switch that chooses between the two as opposed to on/off switches for each, that way both elements can not be on simultaneously thus preventing an overload. I am guessing pre contactor or SSR?

Thanks in advance for any help, I really appreciate it.

Edit: I just thought of another possible option, instead of a 2 way switch (HLT or BK) maybe a 3 way switch (HLT, off, BK) that would remove the need for a separate element switch.

https://www.homebrewtalk.com/f170/110v-recirculating-ebiab-2-5-gallon-batches-341219/

My current setup is a double keggle system, one for the hot liquor tank and one for the boil kettle, with a 10 gallon water cooler mash tun and a March pump. I have a single 2000w heating element in each keg, which has served me well so far but I would like finer control and to stop physically plugging elements in. My problem lies in that I currently have access to a single 20A circuit to brew off of. So this controller will need to control both elements, but only one at a time (i.e. the HLT OR the BK, no need to have both running). Further I don't really need the PID to control the BK, at least not automatically the temp probe will live in the HLT (it all ready has a thermowell). I really like the design of the following post.

I would like something very similar but with the option of choosing which element is on and an indicator light to remind me which one is. I was thinking a switch that chooses between the two as opposed to on/off switches for each, that way both elements can not be on simultaneously thus preventing an overload. I am guessing pre contactor or SSR?

Thanks in advance for any help, I really appreciate it.

Edit: I just thought of another possible option, instead of a 2 way switch (HLT or BK) maybe a 3 way switch (HLT, off, BK) that would remove the need for a separate element switch.

https://www.homebrewtalk.com/f170/110v-recirculating-ebiab-2-5-gallon-batches-341219/