Arrheinous

Well-Known Member

I've just done my eighth all-grain batch last weekend (brewing extract and all-grain for two years total). I batch sparge - usually with a 1.25qt/# grist ratio (no less than 4 gallons total though) and splitting up the sparging into two quick sparges. The mash tun is a Coleman Extreme with a 12" bazooka screen. Typically I expect a boil-off of 1 gallon to get me down to a 5 gallon batch (my rate is more like 1.3/hr after this last batch).

Been having problems getting above 1.070 as I've been playing around with my set-up and still learning a bunch of things about mashing/sparging.

To address this problem, I went through all my brew data to figure out how much more grain I need to add to account for my typical efficiencies for a given target OG.

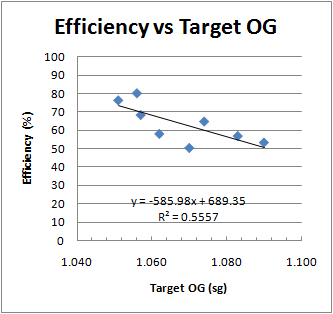

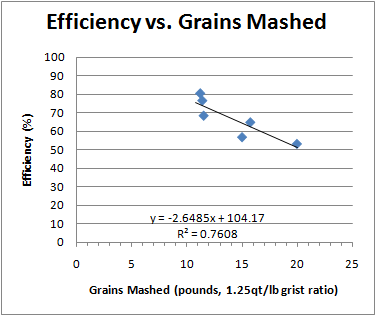

In a lot of the threads/articles on batch sparging, I read about a drop in efficiency at higher attempted gravities. The data here follows that pretty well and hopefully this gives some insight for others with a similar problem.

---

Here are my numbers up front. "Efficiency" is calculated by OG at the fermenter divided by the potential SG of the grains given 100% efficiency.

Outliers:

4 (Tripel) - First time at lower temperature mashing (tripel), didn't mash for long enough

6 (Cream Stout) - The mash tun just wasn't flowing properly and backed up, I blame it on the wheat/oat but should have used rice hulls

but should have used rice hulls

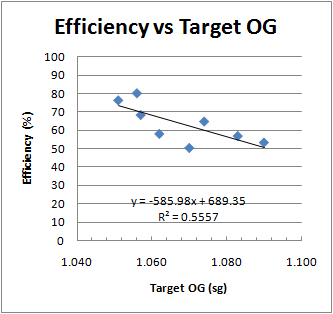

The plot that says the most is "efficiency vs. target OG". This follows a pretty decent trend (the 50% at 1.070 is from not mashing a tripel long enough):

So for batch spargers with average efficiencies, you need to make some considerations before jumping into a bigger beer with a recipe set at 75%.

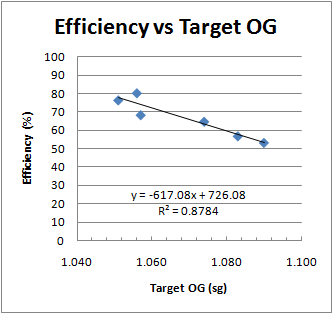

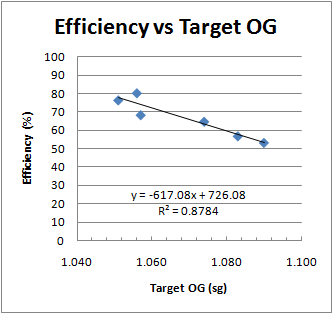

If I selfishly scrub out the two outliers then the trend fits better. From here on out I'll exclude the tripel and cream stout trials which had obvious problems.

Going from 80% at 1.050 to 55% at 1.090 means a drop of 0.375% / 0.001 sg.

Efficiency is said to vary with OG due to the amount of grains and water used in the mash paired with the limited volumes of wort you want to collect. This looks pretty true even with the six trials left.

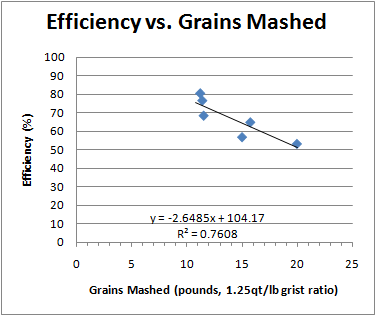

Doubling the grain from ~10# to 20# seems to drop the efficiency from 75% to 50%. Twice the grain cuts efficiency by 1/3?

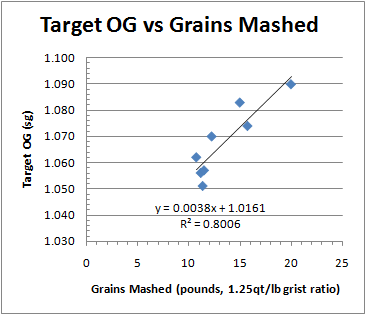

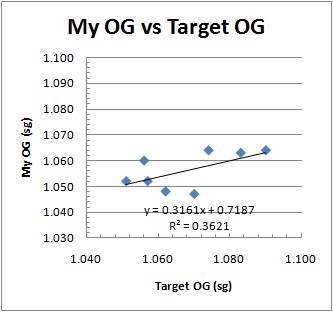

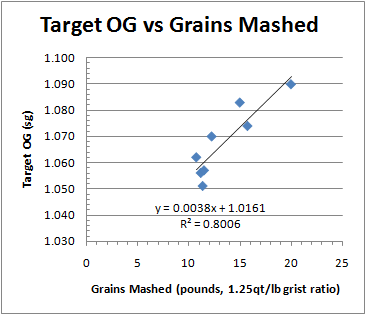

I was then curious if grains and OG really had that much relationship to one another - given the lesser contributions of kilned grains that some recipes rely heavily on. But the amount of grains mashed factors in pretty well to OG.

About 10# of grain in the recipe adds something like 0.045 to the target OG. But most of this is coming from pale malt.

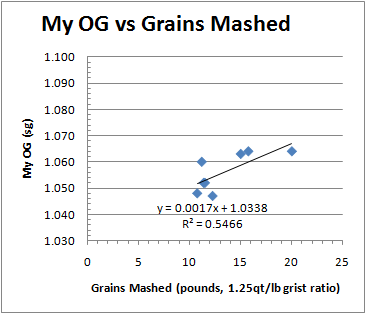

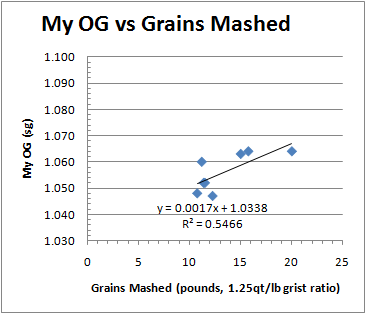

Looking at the other side of the coin, my OG vs. mashed grains shows a different picture. It looks like the OG isn't really rising after 13# or so of grain in the mash tun.

This plateau seems to signify some limit to conversion or lautering at higher amounts of grain in the tun in my process.

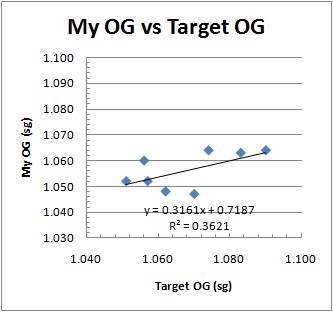

My bottom-line comes out to this plot here. To hit a given target OG I need to start from a higher OG and let the lower efficiencies bring it down into the desired range.

But even at the upper ranges I haven't been able to beat 1.070 OG even with the bragot attempt. 1.070 falls in at around 13# of grain which is where my OG vs. grains mashed is plateauing. My system isn't making effective use of anything over 13# of grain.

I haven't tested mash completion with iodine nor have I tested mash pH to make sure I'm within the right range - I'll have those test materials for the next batch.

It doesn't look like I have a high pH problem because the lower gravity batches come out near 80% efficiency even with a lack of darker malts to buffer the pH toward the right range. The higher gravity beers have had darker malts which can contribute more acids so it may be possible my mash pH is too low? My city water report gives an alkalinity of 78 and a pH near 7.5.

Temperature drop in the cooler and mixing could be a factor but I'm pretty rigorous about mashing in and checking to make sure the temperature is reading correctly at various locations in the tun.

Anyway, hopefully this data gives people some points for analyzing their own efficiencies and scheming to scale up into higher gravity beers (YMMV). If anyone else has these sorts of plots handy then I'd like to take a look.

Been having problems getting above 1.070 as I've been playing around with my set-up and still learning a bunch of things about mashing/sparging.

To address this problem, I went through all my brew data to figure out how much more grain I need to add to account for my typical efficiencies for a given target OG.

In a lot of the threads/articles on batch sparging, I read about a drop in efficiency at higher attempted gravities. The data here follows that pretty well and hopefully this gives some insight for others with a similar problem.

---

Here are my numbers up front. "Efficiency" is calculated by OG at the fermenter divided by the potential SG of the grains given 100% efficiency.

Code:

Brew# Reciped Based On

Target #Grain My OG Eff (%) Source

1 Bragot (Radical Brewing) 1.090 20 1.064 53 Radical Brewing, Randy Mosher

2 Scotch Ale (Walker) 1.056 11.19 1.060 80 https://www.homebrewtalk.com/f65/walkers-gruagach-80-a-148886/

3 Red Rye APA (cweston) 1.051 11.38 1.052 76 https://www.homebrewtalk.com/f70/red-rye-ale-25929/

4 Belgian Tripel (LHBS)* 1.070 12.25 1.047 50 http://www.grapeandgranary.com/agrecpdf/ag80.pdf

5 Anchor Steam Clone (Yooper) 1.057 11.5 1.052 68 https://www.homebrewtalk.com/f63/california-common-anchor-steam-clone-extract-ag-54301/

6 Deception Cream Stout(NCBeernut)1.062 10.75 1.048 58 https://www.homebrewtalk.com/f68/deception-cream-stout-141483/

7 Foreign Extra Stout (BYO) 1.074 15.75 1.064 65 http://byo.com/stories/item/2270-foreign-extra-stout

8 Imperial Irish Red (jstuts2260) 1.083 15 1.063 57 https://www.homebrewtalk.com/f12/imperial-irish-red-christmas-ale-272931/Outliers:

4 (Tripel) - First time at lower temperature mashing (tripel), didn't mash for long enough

6 (Cream Stout) - The mash tun just wasn't flowing properly and backed up, I blame it on the wheat/oat

The plot that says the most is "efficiency vs. target OG". This follows a pretty decent trend (the 50% at 1.070 is from not mashing a tripel long enough):

So for batch spargers with average efficiencies, you need to make some considerations before jumping into a bigger beer with a recipe set at 75%.

If I selfishly scrub out the two outliers then the trend fits better. From here on out I'll exclude the tripel and cream stout trials which had obvious problems.

Going from 80% at 1.050 to 55% at 1.090 means a drop of 0.375% / 0.001 sg.

Efficiency is said to vary with OG due to the amount of grains and water used in the mash paired with the limited volumes of wort you want to collect. This looks pretty true even with the six trials left.

Doubling the grain from ~10# to 20# seems to drop the efficiency from 75% to 50%. Twice the grain cuts efficiency by 1/3?

I was then curious if grains and OG really had that much relationship to one another - given the lesser contributions of kilned grains that some recipes rely heavily on. But the amount of grains mashed factors in pretty well to OG.

About 10# of grain in the recipe adds something like 0.045 to the target OG. But most of this is coming from pale malt.

Looking at the other side of the coin, my OG vs. mashed grains shows a different picture. It looks like the OG isn't really rising after 13# or so of grain in the mash tun.

This plateau seems to signify some limit to conversion or lautering at higher amounts of grain in the tun in my process.

My bottom-line comes out to this plot here. To hit a given target OG I need to start from a higher OG and let the lower efficiencies bring it down into the desired range.

But even at the upper ranges I haven't been able to beat 1.070 OG even with the bragot attempt. 1.070 falls in at around 13# of grain which is where my OG vs. grains mashed is plateauing. My system isn't making effective use of anything over 13# of grain.

I haven't tested mash completion with iodine nor have I tested mash pH to make sure I'm within the right range - I'll have those test materials for the next batch.

It doesn't look like I have a high pH problem because the lower gravity batches come out near 80% efficiency even with a lack of darker malts to buffer the pH toward the right range. The higher gravity beers have had darker malts which can contribute more acids so it may be possible my mash pH is too low? My city water report gives an alkalinity of 78 and a pH near 7.5.

Temperature drop in the cooler and mixing could be a factor but I'm pretty rigorous about mashing in and checking to make sure the temperature is reading correctly at various locations in the tun.

Anyway, hopefully this data gives people some points for analyzing their own efficiencies and scheming to scale up into higher gravity beers (YMMV). If anyone else has these sorts of plots handy then I'd like to take a look.