Just wrapped up a brew day and had a hell of a time with my new dudadiesel 30 plate chiller. I had it mounted vertically, and the wort was running out at 105 with about 65* tap water, after the pre-chiller. I fiddled with flow rates for a good 15 minutes before moving it horizontal to get better access to the sink, and blamo, 72 degree outflow. Has anyone else experienced this? If not, heads up, looks like you need this mounted horizontally for efficient cooling.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dudadiesel plate chiller needs to be horizontal?

- Thread starter bmick

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

psbuckland

Well-Known Member

I just got my DD chiller and brewed with it one time. I had similar issues and ended up putting a ball valve on the water out port to keep the cooling water leaving the cooler at a slower rate. Don't know if this helps...it's still a great chiller...

Flyingcow

Member

Water flowing downhill beer flowing up, or the other way around?

Chances are you were getting some kind of pooling or funky flow. That's kinda interesting. It's possible that the wort (or water) favors some plate paths over others when you have it vertical and some of your plates don't get as much flow as they should.

Chances are you were getting some kind of pooling or funky flow. That's kinda interesting. It's possible that the wort (or water) favors some plate paths over others when you have it vertical and some of your plates don't get as much flow as they should.

Shockerengr

Well-Known Member

- Joined

- Feb 22, 2007

- Messages

- 469

- Reaction score

- 34

mines been vertical for a couple years now and I've never had a problem with chilling...

65* well water, and I get about 70* wort out at around 1gpm with 5gpm of cooling water in.

65* well water, and I get about 70* wort out at around 1gpm with 5gpm of cooling water in.

samc

Well-Known Member

horizontal or vertical made NO difference in my Duda chiller. Are you sure you had it counter flowed with wort/water connections? Or possibly you had some vacuum or blockage situation created which worked itself out with the change in orientation. I've never been able to get that few degree differential like above poster mentions, but 10 degrees is doable if I let the wort cool a bit with a flame out hop addition.

edit - the one time I had it hooked up non counterflow I got 100F wort out.

edit - the one time I had it hooked up non counterflow I got 100F wort out.

stubbornman

Well-Known Member

The above is also my guess. You should make sure your inputs (water/wort) are flowing in opposite directions.

I have been reading a lot about plate chillers as I am looking to get one myself. For what I read people seem to get the best eff. one of two ways. 1. the plate chiller is mounted horizontally, 2. the flow of wort is unrestricted. This got me to hypothesis there is a specific way to run a plate chiller to maximize efficiency. As you can see by the diagram from duda diesel the liquid does not wind back and forth through the plate but gets dispersed through several paths.

Now lets take some scenarios into account

1. Everything fully open with max flow rates - All paths will be full of liquid maximizing the heat transfer at one given time. However, with the liquid flowing so quickly the time coefficient is low.

2. Water flow fully open, wort flow restricted BEFORE chiller. - Water paths will be full, but the wort paths only partially full lowering the surface area (vertically mounted the wort will only be in contact with the bottom parts of the plate. horizontally mounted only a portion of the plated will be filled, with the top plates by the input/output will have decreased volume if any at all)

3. water flow fully open, wort flow restricted AFTER chiller. - Water and wort paths will be full, but flow rate of the wort will be slowed coming out increasing both surface area and time of contact with all plates. (mounted vertically with the wort out at the top would push all the air out of the plates filling them with just wort but may not fill all water paths. Mounted vertically with the water out at the top would work oppositely and prevent the wort from filling all the plates. However, mounted horizontally would push the air out filling all paths for both the water and the wort.)

As you can see I hypothesis that scenario 3 will be the best way to maximize heat transfer. To achieve this, one would need to mount the chiller horizontally, and attach a restrictor (ball valve) after the wort has been cooled. I would like to say this is a hypothesis and has yet to be tested.

Edit - horizontal referrers to the input/outputs facing up not sideways

Now lets take some scenarios into account

1. Everything fully open with max flow rates - All paths will be full of liquid maximizing the heat transfer at one given time. However, with the liquid flowing so quickly the time coefficient is low.

2. Water flow fully open, wort flow restricted BEFORE chiller. - Water paths will be full, but the wort paths only partially full lowering the surface area (vertically mounted the wort will only be in contact with the bottom parts of the plate. horizontally mounted only a portion of the plated will be filled, with the top plates by the input/output will have decreased volume if any at all)

3. water flow fully open, wort flow restricted AFTER chiller. - Water and wort paths will be full, but flow rate of the wort will be slowed coming out increasing both surface area and time of contact with all plates. (mounted vertically with the wort out at the top would push all the air out of the plates filling them with just wort but may not fill all water paths. Mounted vertically with the water out at the top would work oppositely and prevent the wort from filling all the plates. However, mounted horizontally would push the air out filling all paths for both the water and the wort.)

As you can see I hypothesis that scenario 3 will be the best way to maximize heat transfer. To achieve this, one would need to mount the chiller horizontally, and attach a restrictor (ball valve) after the wort has been cooled. I would like to say this is a hypothesis and has yet to be tested.

Edit - horizontal referrers to the input/outputs facing up not sideways

As you can see I hypothesis that scenario 3 will be the best way to maximize heat transfer. To achieve this, one would need to mount the chiller horizontally, and attach a restrictor (ball valve) after the wort has been cooled. I would like to say this is a hypothesis and has yet to be tested.

Edit - horizontal referrers to the input/outputs facing up not sideways

Yeah, since I originally posted I've done a few tests with the chiller, tinkering with positioning, flow rate, etc etc. My process is now essentially your scenario 3, but I also knock down the temp with a immersion right at flameout to get to 170-180, which takes literally 2 minutes, then transfer the immersion to an ice-bucket to act as a pre-chiller for my plate chiller (even in winter, my water comes out at about 70-75). The ball valve flow restriction on the wort out port made a big difference. I can get from the 170-180 range to pitching temps (~68) in about 10 minutes. Word to the wise, get some hose clamps for your water hoses if you're going to be running the water full blast, you'll thank me.

I have used my plate chiller 3 times now.

First time i had my chiller Horizontal, my tap water was 70F so i was expecting to see a post chilled temp of about 72, 74 maybe?

Nope i had wort coming out at 84-86F with the garden hose on full tap. after a while i started to play with the water hose rate and found that about 1/2 way i was getting better cooling. got it down to 78F my wort ended up at 82F after sitting for 30 minutes and i foolishly just pitched instead of waiting.

(that beer ended up really good though!)

2nd attempt i decided to freeze a small bucket of water. when it was time to chill the wort my water temp was 68, maybe 66F? but again my wort was coming out in the 80s , i put the block of ice on top and now it was coming out in the 70s .

So i looked for documentation on dudadiesel.com and could not find any

so i emailed their support , with photos asking if i should use Vertical, Horizontal ... or *drum roll* with the chiller on its back.

their answer, put the chiller on its back.

this 3rd brew, we got some snow , ice and really really cold weather. tap water is now 52-54F . i Bravely / foolishly skipped making an ice block .

i set the plate chiller on its back and opened up my keggle , wort flows through but i can't see a reading on the throughmeter.. OH NO ! i reach for a pyrmometer really quickly in fear that the wort is off the chart. i scan the throumeter to confirm, yes its off the chart !!

off the chart cause its too cold! my wort was coming out at 54F . In at 200F out at 54F with 52F tap water.. omfg

I use a 15.5 gallon Keggle with a 1/2" threaded ball valve, but a 3/8" dip tube and 3/8" barbed end. that runs 3/8 down to my Dudadiesel B3-12A 30plate (using 3/8" barb ends 1/2 " threaded adaptors) to the thrumeter (also 3/8") and then down into my fermenter.

Honestly i'm still in shock.

oh also i had to throttle the cooling water WAY back (20% full throttle?) so that the wort would come out in the mid 60s. I ended up with a final temp of 61F . I was aiming for 68F ... so i'm really happy i was able to miss my mark in the awesome direction .

First time i had my chiller Horizontal, my tap water was 70F so i was expecting to see a post chilled temp of about 72, 74 maybe?

Nope i had wort coming out at 84-86F with the garden hose on full tap. after a while i started to play with the water hose rate and found that about 1/2 way i was getting better cooling. got it down to 78F my wort ended up at 82F after sitting for 30 minutes and i foolishly just pitched instead of waiting.

(that beer ended up really good though!)

2nd attempt i decided to freeze a small bucket of water. when it was time to chill the wort my water temp was 68, maybe 66F? but again my wort was coming out in the 80s , i put the block of ice on top and now it was coming out in the 70s .

So i looked for documentation on dudadiesel.com and could not find any

so i emailed their support , with photos asking if i should use Vertical, Horizontal ... or *drum roll* with the chiller on its back.

their answer, put the chiller on its back.

this 3rd brew, we got some snow , ice and really really cold weather. tap water is now 52-54F . i Bravely / foolishly skipped making an ice block .

i set the plate chiller on its back and opened up my keggle , wort flows through but i can't see a reading on the throughmeter.. OH NO ! i reach for a pyrmometer really quickly in fear that the wort is off the chart. i scan the throumeter to confirm, yes its off the chart !!

off the chart cause its too cold! my wort was coming out at 54F . In at 200F out at 54F with 52F tap water.. omfg

I use a 15.5 gallon Keggle with a 1/2" threaded ball valve, but a 3/8" dip tube and 3/8" barbed end. that runs 3/8 down to my Dudadiesel B3-12A 30plate (using 3/8" barb ends 1/2 " threaded adaptors) to the thrumeter (also 3/8") and then down into my fermenter.

Honestly i'm still in shock.

oh also i had to throttle the cooling water WAY back (20% full throttle?) so that the wort would come out in the mid 60s. I ended up with a final temp of 61F . I was aiming for 68F ... so i'm really happy i was able to miss my mark in the awesome direction .

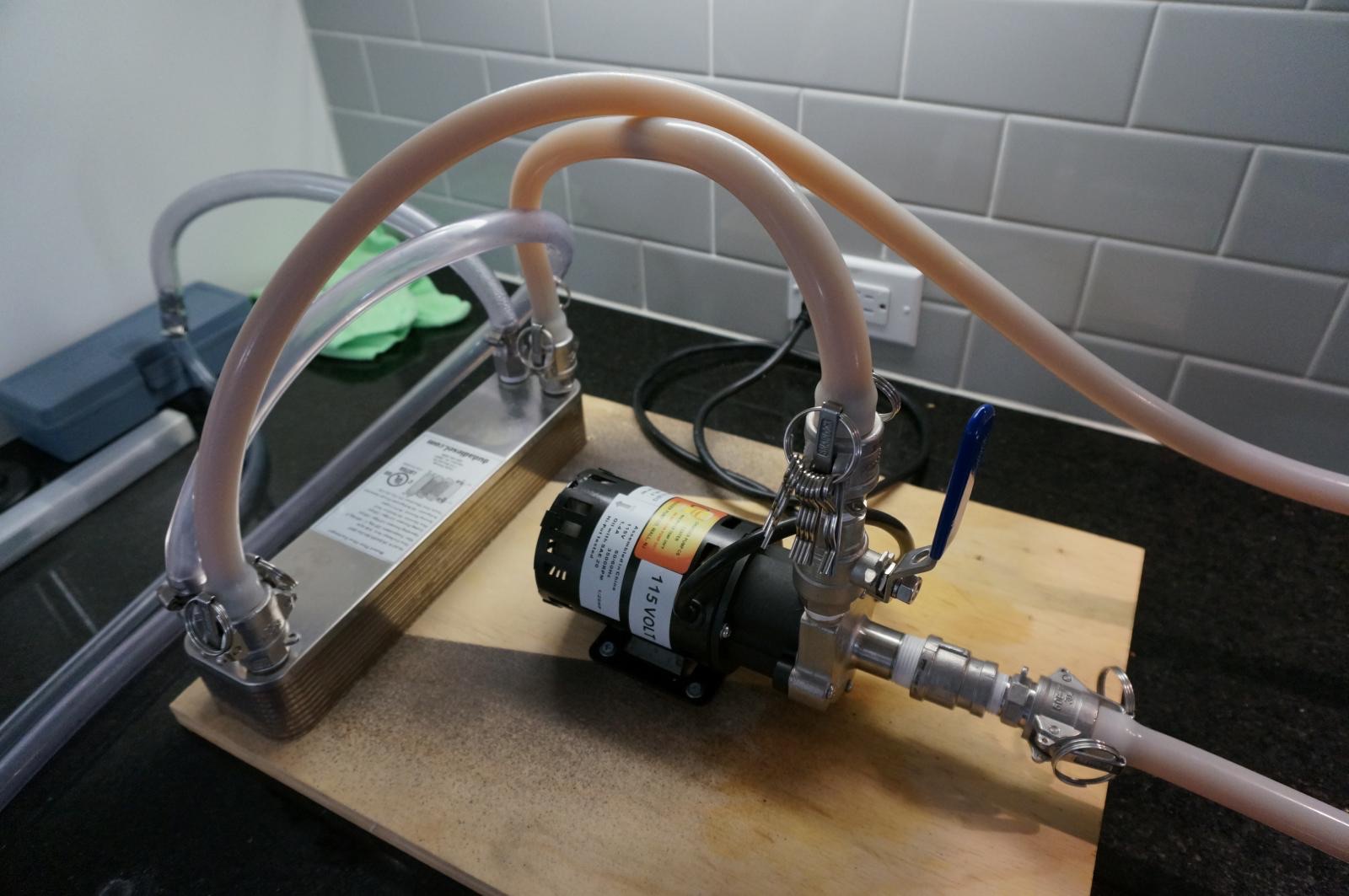

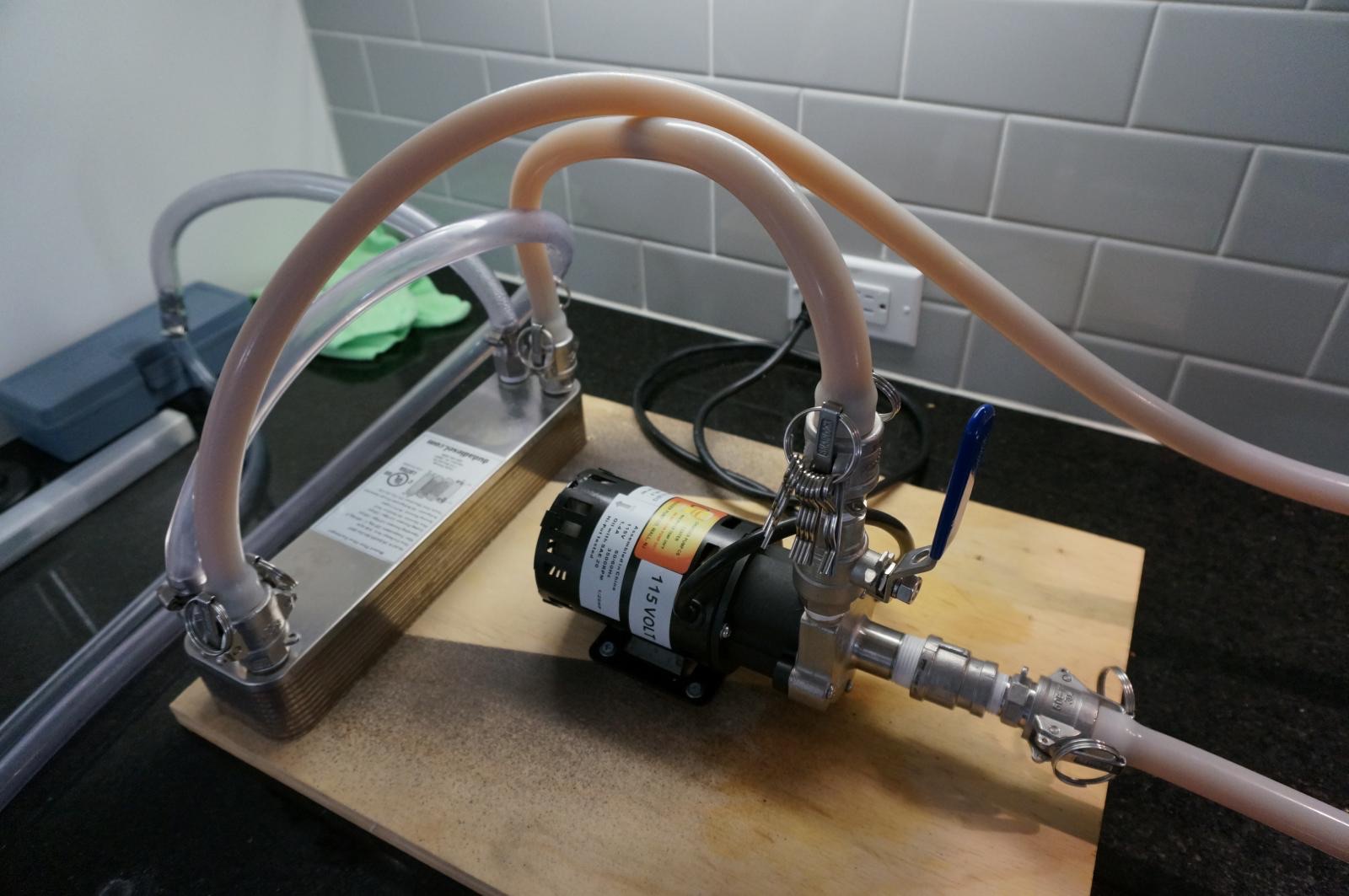

Is this what you mean by on its back? This is how I use mine.

Last pic was a bit small

augiedoggy

Well-Known Member

So by on its back you mean with the fittings pointed up?

YES, like above^^

Think about it....That way the way both the water and wort displace the air and push it out effectively without trapped pockets regardless of flow pressure.... the water side fills from the bottom up.

IN a nutshell if you have high pressure on the wort and water going into the chiller and it effectively pushs most of the the air pockets out regardless of position it doesnt matter but I had mounted mine sideways on a board and found I get air pockets at the top that are filled with trapped air....

solution is to mount it on its back but not in a permanent fashion, this way one can pick it up and tip it to "drain it out".

this is what I plan on doing.

This is an interesting topic. I've always used mine like Gavin C does (as in the pic), but never thought of it that much.

Now I would call that "horizontal," going by the orientation of the plates.

I wonder, if putting the restrictor valve on the chiller's wort outlet, instead of the pump, would create more pressure and fill the channels more completely.

Now I would call that "horizontal," going by the orientation of the plates.

I wonder, if putting the restrictor valve on the chiller's wort outlet, instead of the pump, would create more pressure and fill the channels more completely.

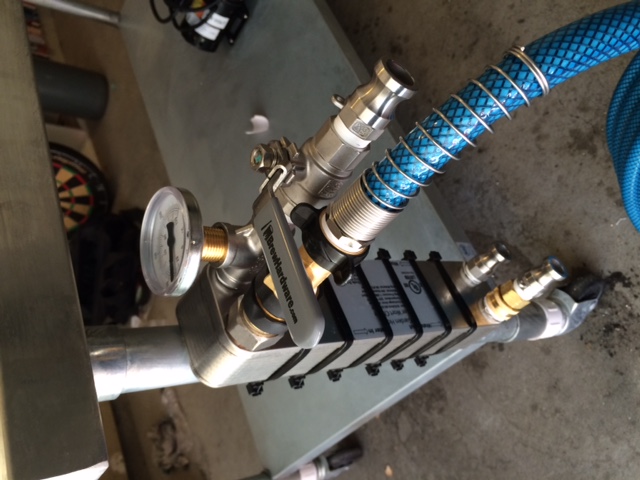

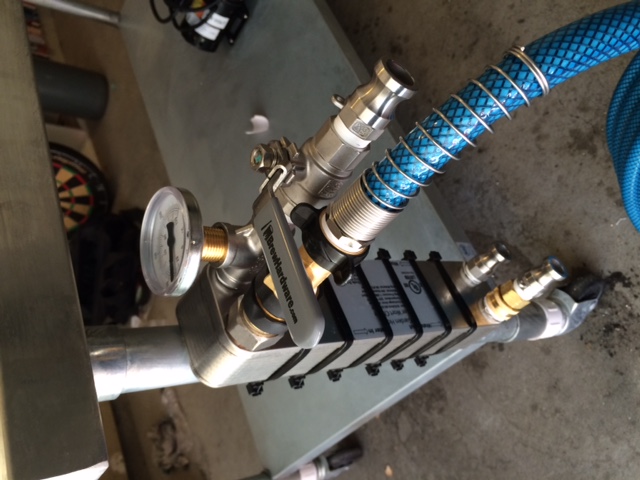

Brettomomyces

LHBS Curmudgeon

Here's how I have mine setup, vertical with cold water top -> down and hot wort bottom -> up. I keep both valves going full during the chilling and recirculate the hot wort back into the BK until the wort coming out is the temperature I want going into the fermenter. Then I cut the pump, close all the valves, switch the out hose to the fermenter and open up again/turn on the pump. It's a 20 plate duda so a little smaller than most, but this method works really well for me. I recirculate for about 5 minutes total usually, longer for lagers. Ground water is pretty cold here.

The recirculating brings down the temp inside the BK to about 120 before I move into the fermenter, which is great considering how fast it is. It also helps to setup my false bottom to catch hops and some of the break material.

The recirculating brings down the temp inside the BK to about 120 before I move into the fermenter, which is great considering how fast it is. It also helps to setup my false bottom to catch hops and some of the break material.

Here's how I have mine setup, vertical with cold water top -> down and hot wort bottom -> up. I keep both valves going full during the chilling and recirculate the hot wort back into the BK until the wort coming out is the temperature I want going into the fermenter. Then I cut the pump, close all the valves, switch the out hose to the fermenter and open up again/turn on the pump. It's a 20 plate duda so a little smaller than most, but this method works really well for me. I recirculate for about 5 minutes total usually, longer for lagers. Ground water is pretty cold here.

I guess another benefit of this setup is that it's easy to catch spills when you disconnect your chiller.

The recirculating brings down the temp inside the BK to about 120 before I move into the fermenter, which is great considering how fast it is. It also helps to setup my false bottom to catch hops and some of the break material.

I really like your setup with the temperature probe at the wort out. I might have to put together that setup myself. I also recirculate for cooling as you describe minus a false bottom. I like to leave the pump full throttle and tidy/organize other things during the cooling. Approximately 10-12 minutes for me for my 5.5 gallon batches. My groundwater is very warm most of the year so I use a pre-chiller, (my immersion chiller). I still have not chilled directly to the fermenter as I would really like to monitor the temperature more closely. I ferment in glass so don't want any thermal shock accidents.

As an off topic aside I like that you have kept your yeast whisperer moniker given in the "Ask me anything thread". Great input there BTW.

Brettomomyces

LHBS Curmudgeon

I really like your setup with the temperature probe at the wort out. I might have to put together that setup myself. I also recirculate for cooling as you describe minus a false bottom. I like to leave the pump full throttle and tidy/organize other things during the cooling. Approximately 10-12 minutes for me for my 5.5 gallon batches. My groundwater is very warm most of the year so I use a pre-chiller, (my immersion chiller). I still have not chilled directly to the fermenter as I would really like to monitor the temperature more closely. I ferment in glass so don't want any thermal shock accidents.

As an off topic aside I like that you have kept your yeast whisperer moniker given in the "Ask me anything thread". Great input there BTW.

Thanks! The thermometer was a really easy add on, 1/2" MPT thermometer from ebay with a 2" stem for I think $15 and then I just added a stainless T and a threaded nipple to put the ball valve on. So, $20 all together.

Yep mine runs exactly like Gavin C, with the fittings facing the ceiling! but with 3/8 line and gravity feed. My 52F tap water definitely is a huge help. But I'm also pretty darn close to the .98 Gal/min wort flow rate that the dudadiesel chart uses ..

my tube also goes up from the wort chiller over the side of my brew bucket and back down.. not sure how that changes the pressure , helps or hinders ... about a 3" rise and back down..

=)

my water hits at least 72F last summer, which was a bit of a mild one, but then again the water supply is all snow run off (lucky me) but its also really hard water ... *shrugs* but its what I get

my tube also goes up from the wort chiller over the side of my brew bucket and back down.. not sure how that changes the pressure , helps or hinders ... about a 3" rise and back down..

=)

my water hits at least 72F last summer, which was a bit of a mild one, but then again the water supply is all snow run off (lucky me) but its also really hard water ... *shrugs* but its what I get

Similar threads

- Replies

- 3

- Views

- 638

- Replies

- 9

- Views

- 1K

- Replies

- 4

- Views

- 1K

- Replies

- 14

- Views

- 1K