btbnl

Well-Known Member

Having moved my keezer more often than is good for either of us, I'm thinking a jockey box is in order for the 2-3 times a year I want to run 4+ taps at an event. I've done some reading and costing and now I'm soliciting the general wisdom of brewkind: buy, build or rent? coil or cold-plate? anything else I should be considering?

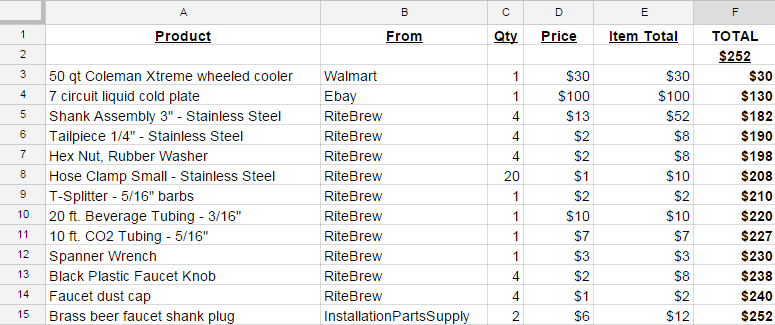

So far it looks buying coils for a DIY project isn't cost-effective, but that building with a cold plate could be a bit cheaper than buying with coils if I can find a deal on a used one. Either way though, once I include all the external hardware (distributor, all lines/disconnects) I'm looking at north of $500, and closer to $700 if I go stainless. Does that seem right?

So far it looks buying coils for a DIY project isn't cost-effective, but that building with a cold plate could be a bit cheaper than buying with coils if I can find a deal on a used one. Either way though, once I include all the external hardware (distributor, all lines/disconnects) I'm looking at north of $500, and closer to $700 if I go stainless. Does that seem right?