DragginFly

Member

- Joined

- Jun 1, 2016

- Messages

- 7

- Reaction score

- 0

I'm designing an onboard water solution for our off road vehicle, and I have a couple of questions that can probably be better answered by home brewers than by overland vehicle tinkerers...

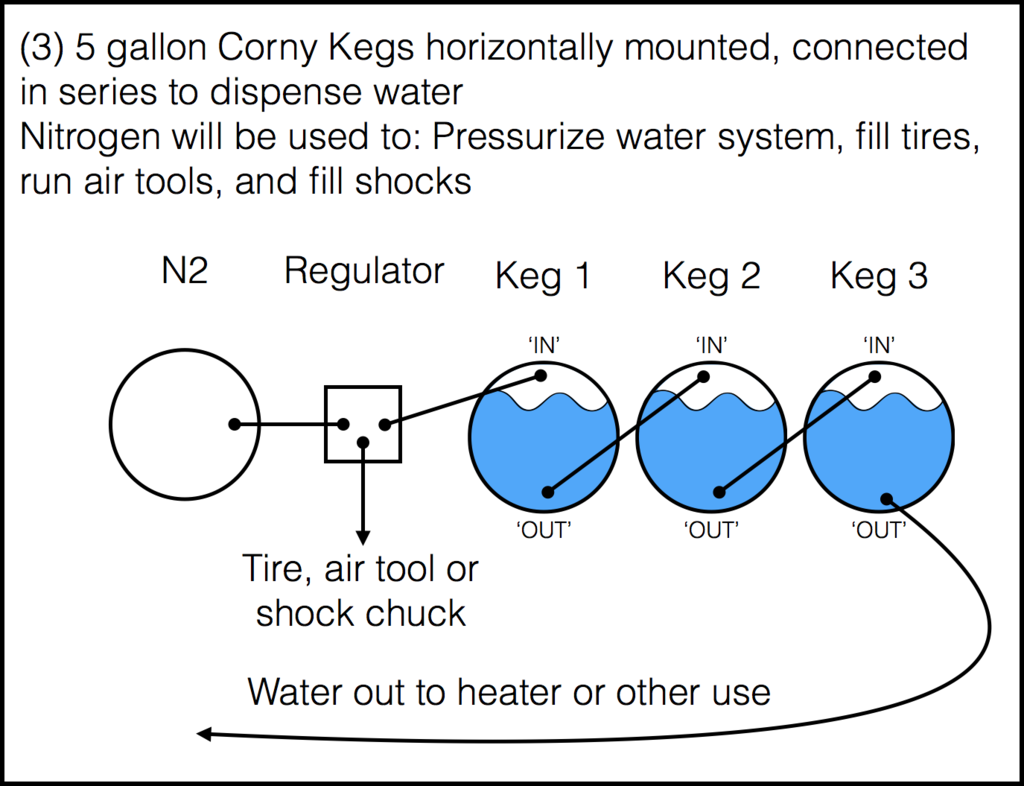

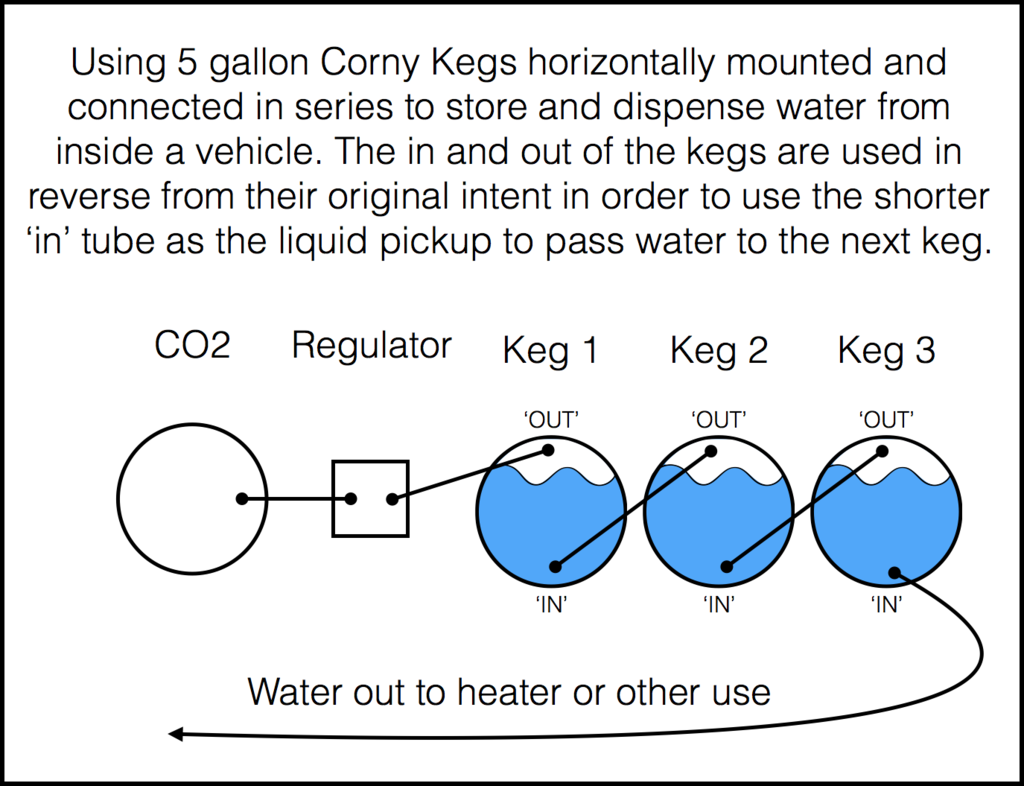

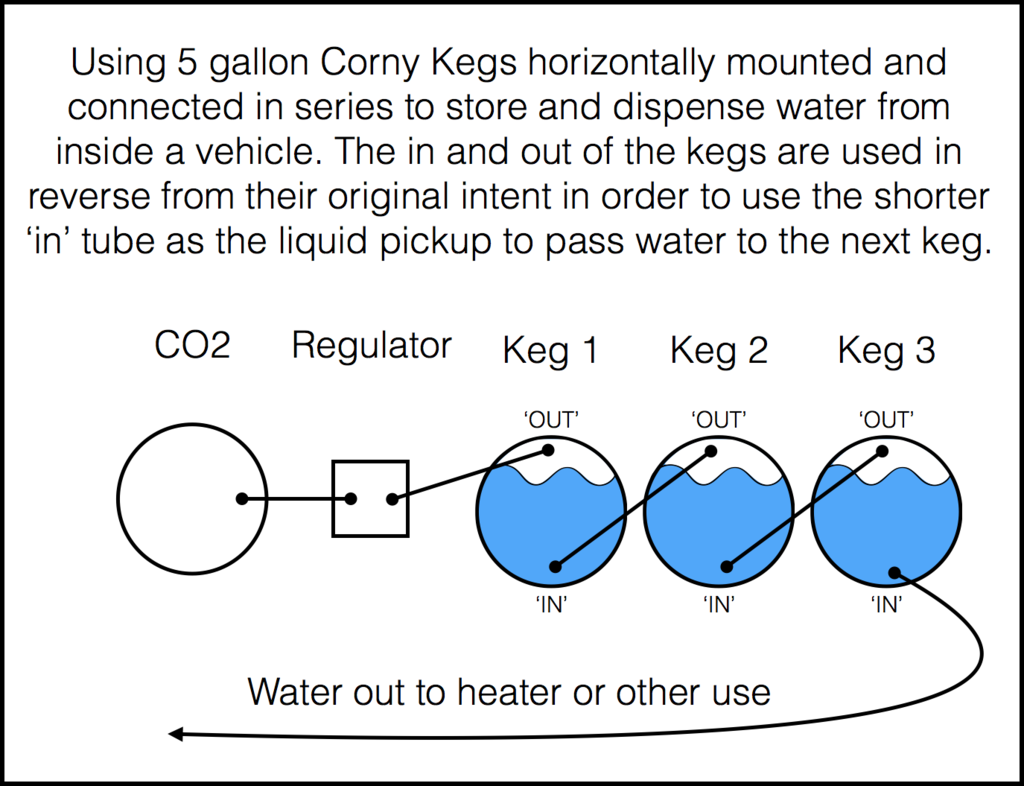

I've searched through this forum (thank you all so much for your posts and ideas!) and have determined that I can probably run 3 corny kegs horizontally by using the 'gas in' port as my water out as long as I keep that port on the bottom when they're laid down. I would then pressurize the system by sending CO2 into the 'beer out' port.

I would like to carry 15 gallons of fresh water in the truck, and be able to dispense it with a small lever-operated spray head like you see in many kitchen sinks:

I would think that I can attach a CO2 bottle to the first keg at the 'out' port, and run the kegs in series until the last keg has the shower head attachment on its 'gas in' port.

CO2 bottle --> Keg 1 'out' - pressurizes K1 and forces water out of the 'in' port

Keg 1 'in' --> Keg 2 'out' - flows water through K2 out of the 'in' port

Keg 2 'in' --> Keg 3 'out' - flows water through K3 to the shower head via the 'in' port

A picture is worth a thousand words:

I remember just enough chemistry to recall Henry's law about dissolved gasses being more likely to go into solution at higher pressure and lower temperature (this has been demonstrated by the way you guys force carbonate in kegs by keeping them cold and at ~30psi for a couple days and/or shaking them to agitate the gas into solution).

I want to AVOID sending the gas into solution, so my question is this: how much pressure do you need in order to force the gas into solution, and if my serving pressure stays below that for around 5 days, will the water absorb the gas all the way down until the system equalizes at 0psi?

As much as we enjoy drinking soda water on a regular basis, I'm sure showering in it would be quite the experience.

Our use case:

TIME - Offroading in our Toyota Tundra for a few days at a time before refilling the water, possibly up to 5 days.

SHAKING the bejeezus out of the kegs as we drive. Imagine these kegs will be on a paint can agitator for a few hours at a time.

TEMPERATURE - We live and drive in the deserts of Arizona, California and Mexico so these kegs will see temps in excess of 140* F when parked in the sun.

I'd love to have some feedback from you about the suggested PSI for this idea to function/store at.

Thanks!

I've searched through this forum (thank you all so much for your posts and ideas!) and have determined that I can probably run 3 corny kegs horizontally by using the 'gas in' port as my water out as long as I keep that port on the bottom when they're laid down. I would then pressurize the system by sending CO2 into the 'beer out' port.

I would like to carry 15 gallons of fresh water in the truck, and be able to dispense it with a small lever-operated spray head like you see in many kitchen sinks:

I would think that I can attach a CO2 bottle to the first keg at the 'out' port, and run the kegs in series until the last keg has the shower head attachment on its 'gas in' port.

CO2 bottle --> Keg 1 'out' - pressurizes K1 and forces water out of the 'in' port

Keg 1 'in' --> Keg 2 'out' - flows water through K2 out of the 'in' port

Keg 2 'in' --> Keg 3 'out' - flows water through K3 to the shower head via the 'in' port

A picture is worth a thousand words:

I remember just enough chemistry to recall Henry's law about dissolved gasses being more likely to go into solution at higher pressure and lower temperature (this has been demonstrated by the way you guys force carbonate in kegs by keeping them cold and at ~30psi for a couple days and/or shaking them to agitate the gas into solution).

I want to AVOID sending the gas into solution, so my question is this: how much pressure do you need in order to force the gas into solution, and if my serving pressure stays below that for around 5 days, will the water absorb the gas all the way down until the system equalizes at 0psi?

As much as we enjoy drinking soda water on a regular basis, I'm sure showering in it would be quite the experience.

Our use case:

TIME - Offroading in our Toyota Tundra for a few days at a time before refilling the water, possibly up to 5 days.

SHAKING the bejeezus out of the kegs as we drive. Imagine these kegs will be on a paint can agitator for a few hours at a time.

TEMPERATURE - We live and drive in the deserts of Arizona, California and Mexico so these kegs will see temps in excess of 140* F when parked in the sun.

I'd love to have some feedback from you about the suggested PSI for this idea to function/store at.

Thanks!