Great start! I can only contribute what I know from doing this from a living. This might not be specific to your screen, but in general.

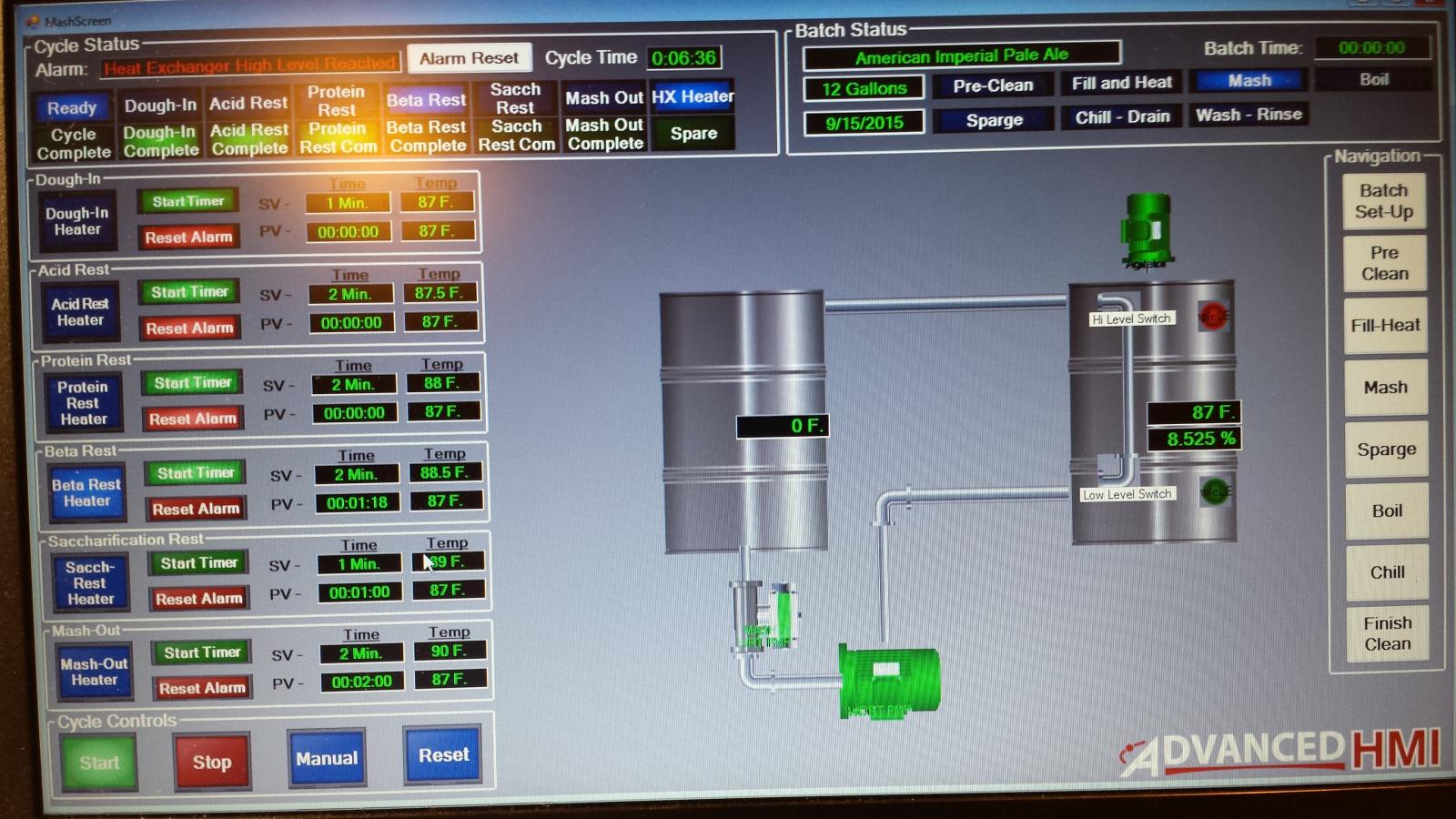

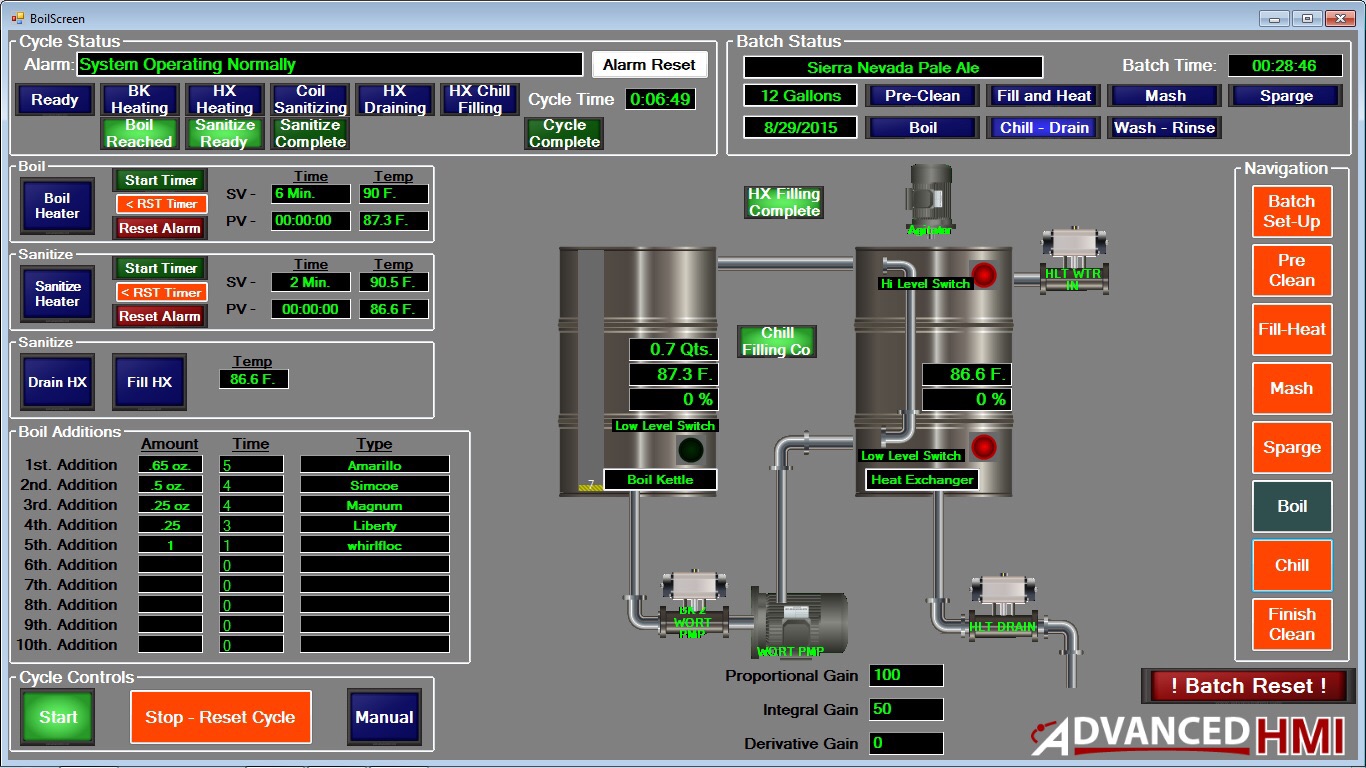

1. Standardized color schemes work. They prevent incidents and convey the right info when you need it. Grey is off, blue is on, red is an alarm condition requiring operator intervention, yellow is manual mode or an interlocked condition, etc... There are guides online on how to follow this standard. The idea is they've done studies on what catches the eyes best.

2. If the batch runs in a simple sequence I would assign a multistate indicator to an integer. If the integer is 0 then the indicator reads "batch idle", 1 would be "heating up boil kettle" or something like that. I see you have what appears to be each step as part of a little box separate for each one or something. Maybe layer them on top and only have the one visible when it's on the correct step.

3. If the sequence is highly automated I would put in a few "acknowledgement" buttons that pop up between batch steps for safety sake or to visually verify certain things did happen correctly.

4. The e-stop is fine, but make sure if you really want something to be an e-stop it needs to be hard-wired in-line with the equipment it de-energizes or the safety control relay that de-energizes the equipment. Relying on an HMI/PLC communications connection for that isn't sufficient in "manufacturing plant" level stuff. I know it's home brew, but if you want it to stop you want it to stop.

5. I don't see it unless I am having male refrigerator blindness, but I'd add a current step timer. A step time total and maybe an estimated step time. Maybe an indicator if one exceeds the other by more than X. Also maybe a total batch timer.

6. Add a manual mode to anything that has automatic control. Something goes awry, put it in manual to stop it or start it.

7. An abort batch step, repeat batch step, hold batch step. Something goes wrong and you fix it you can restart the step. Something goes wrong that doesn't need a restart, just resume. Totally fudged it up, toss it and abort instead of waiting for a sequence to finish.

8. If that HMI has an alarm manager and bar, use it. Configure some alarms based on SP's for the steps, low-low, low, hi, hi-hi. That will help you manually intervene if something goes wrong and save the batch from ruin.

If you're crazy about batch and automation let me recommend: