You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wire gauge question

- Thread starter sethlovex

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

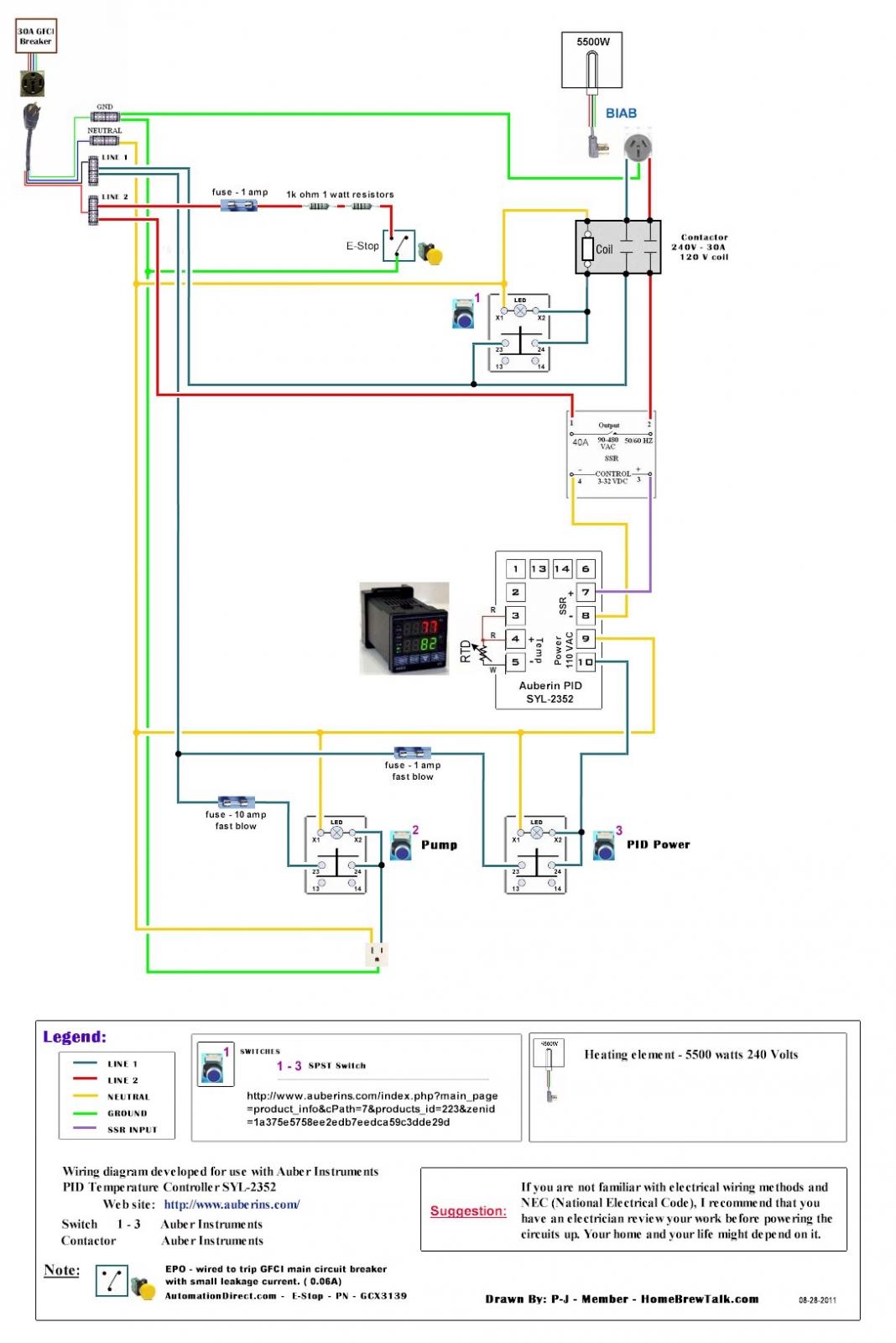

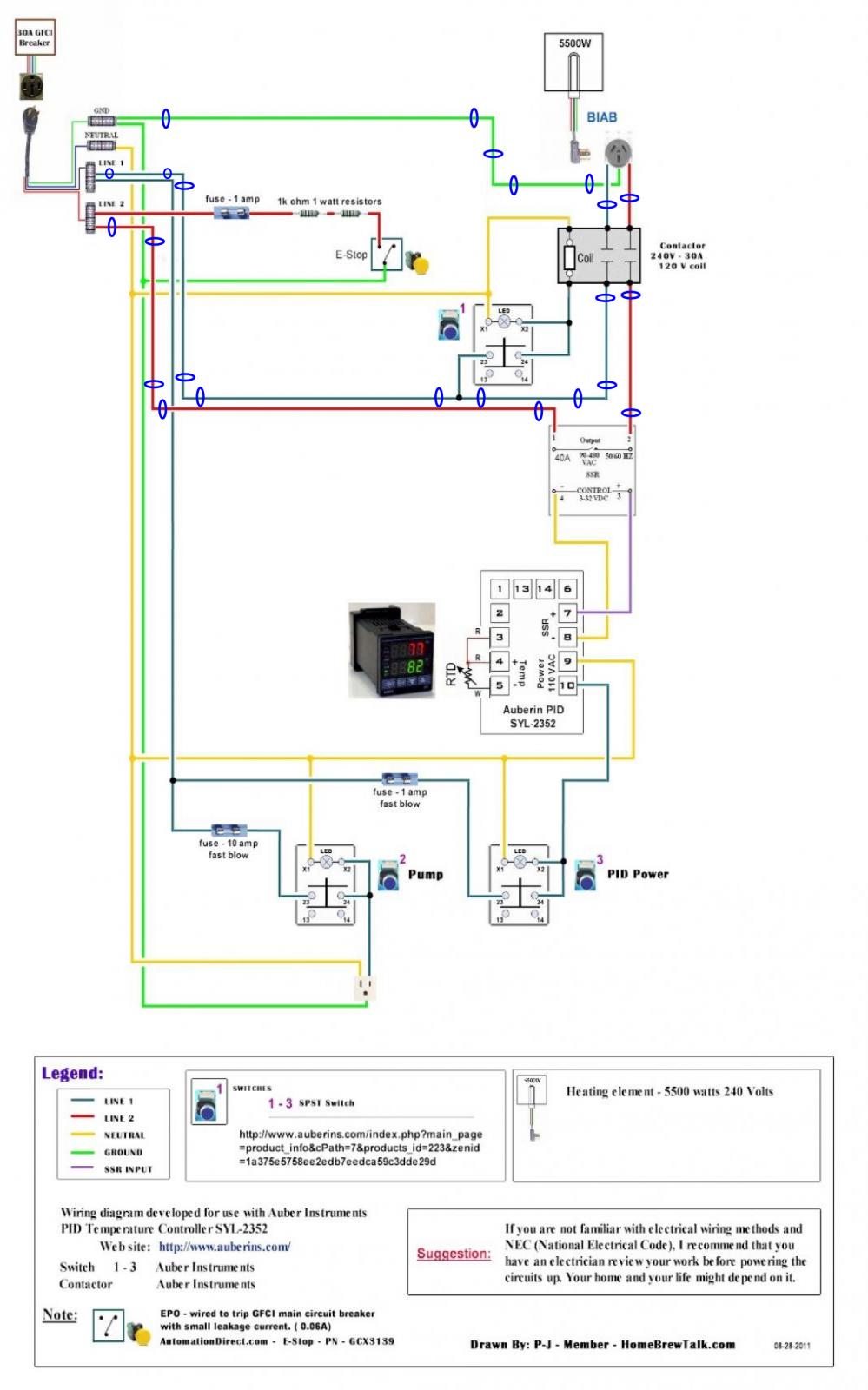

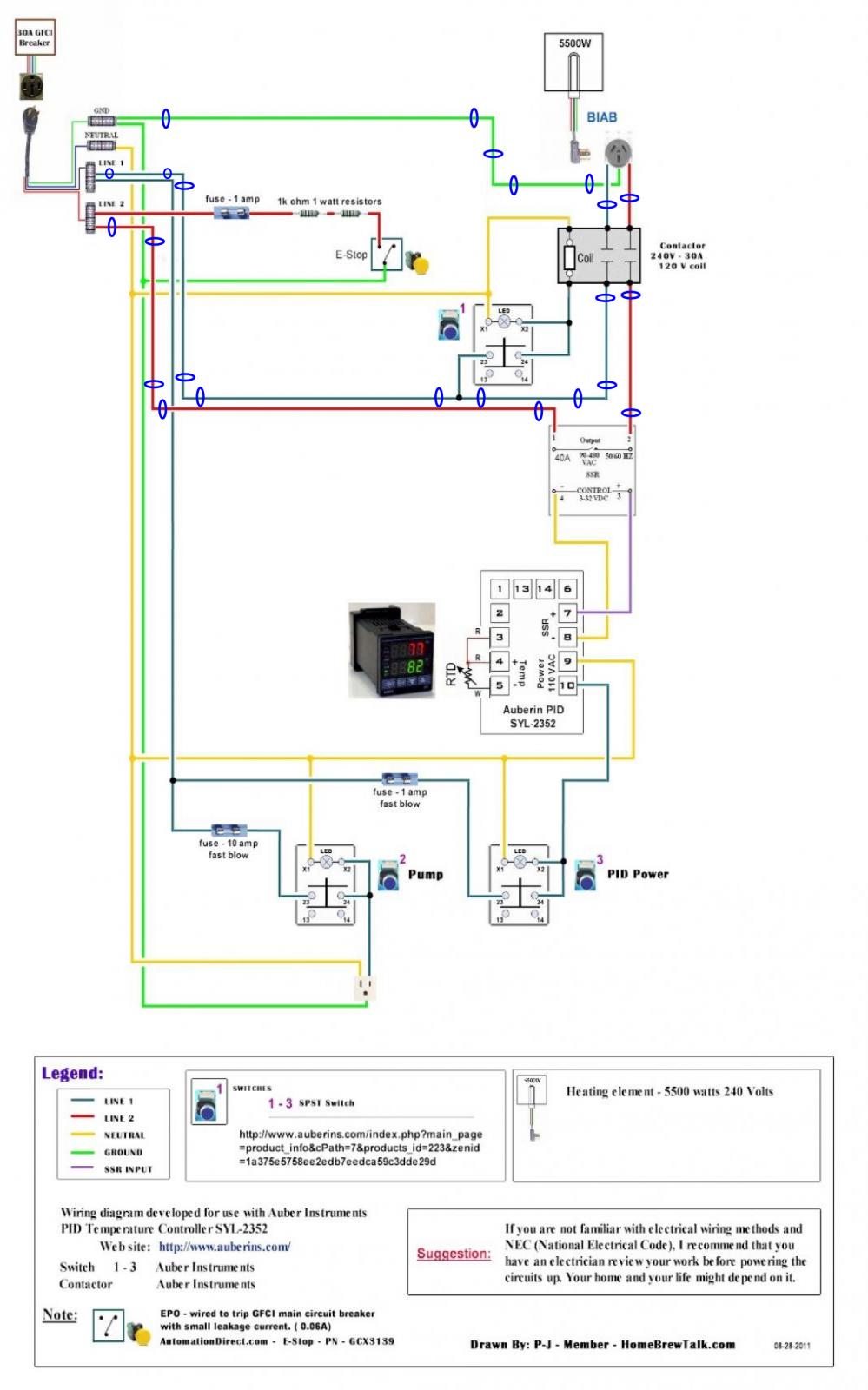

You only need to run 10 gauge wire for the segments marked with blue ellipses in the marked up schematic below. These are the only wires that will carry the ~23 A for the element. All other wiring can be 14 gauge, as it will carry less than 10 A current.

Brew on

Brew on

BlkWater_brewer

Well-Known Member

Not to sound like a broken record here, but... If people insist on using home depot romex then you need the thick wires. It is not the size of the wire but it's insulation type that matters. FTR - 22 gauge TGGT Cable is rated for 300V, 12 amps. 10 gauge TGGT is rated for 600V at 75 amps. Romex is cheap and cumbersome. You can get TGGT from Grainger makes for a tight clean controller without the unnecessary big ass wires. Yes the wire is more expensive only because it comes in larger rolls - use what you need and sell the rest.

Just a pet peeve.

Just a pet peeve.

sethlovex

Well-Known Member

- Joined

- Jan 25, 2013

- Messages

- 189

- Reaction score

- 15

You only need to run 10 gauge wire for the segments marked with blue ellipses in the marked up schematic below. These are the only wires that will carry the ~23 A for the element. All other wiring can be 14 gauge, as it will carry less than 10 A current.

Brew on

Thank you!

Exactly what I was looking for.

sethlovex

Well-Known Member

- Joined

- Jan 25, 2013

- Messages

- 189

- Reaction score

- 15

So my initial question arose when trying to complete the 10 gauge leg feeding the contractor and led 1. Now that I see the led 1 portion can be of smaller gauge, how do you execute this? I'm assuming running 14 gauge back to the terminal bar. Sorry for the noob questions, obviously don't want to use the wrong wire

Last edited:

sethlovex

Well-Known Member

- Joined

- Jan 25, 2013

- Messages

- 189

- Reaction score

- 15

Not to sound like a broken record here, but... If people insist on using home depot romex then you need the thick wires. It is not the size of the wire but it's insulation type that matters. FTR - 22 gauge TGGT Cable is rated for 300V, 12 amps. 10 gauge TGGT is rated for 600V at 75 amps. Romex is cheap and cumbersome. You can get TGGT from Grainger makes for a tight clean controller without the unnecessary big ass wires. Yes the wire is more expensive only because it comes in larger rolls - use what you need and sell the rest.

Just a pet peeve.

I'm using HD THHN stranded for the 10 and 14 should be Ok right

augiedoggy

Well-Known Member

All three pids, timer, amp meter and all my LEDs are all powered off a single pair of 16 or 18g (cant remember) wires protected by a single 1/2a fuse..... That's right all this stuff draws less that 1/2a combined! I can't help but laugh when I see all these pictures with 12 and 14 gauge wiring running to these things.... pids actually have small DC power supplies in them and run off 24v internally from what I've read... even 18g is technically overkill for the amps draw...

The incoming line will be immediately rectified and that DC converted to whatever DC voltages are required by the various components of the device (A/D converter, micro-controller, display, output gate generator....). Most of these will be well below 24V.

All three pids, timer, amp meter and all my LEDs are all powered off a single pair of 16 or 18g (cant remember) wires protected by a single 1/2a fuse..... That's right all this stuff draws less that 1/2a combined! I can't help but laugh when I see all these pictures with 12 and 14 gauge wiring running to these things.... pids actually have small DC power supplies in them and run off 24v internally from what I've read... even 18g is technically overkill for the amps draw...

I believe this is what I will be doing for mine. Tho I wasn't planning on running those things off the same wires, but now I'm thinking about it!!

augiedoggy

Well-Known Member

I believe this is what I will be doing for mine. Tho I wasn't planning on running those things off the same wires, but now I'm thinking about it!!

Mine are piggybacked from one device to the next just like ac outlets in a wall. and one of the wires goes to a power switch first which I use as the main power switch for the control panel. I think I might have used 16g at least to the switch now that I think about it since I also have a 6.5a 24v powers supply for my dc pumps and stirrer as well as relay coils for my elements running off of the same power switch.

You can route the finer gauge wire for the switch/LED either to the terminal block, or the power input terminal on the contactor. Or, you can just run a 10 G from the terminal block to the switch/LED, and another 10 G from the switch/LED to the contactor. But the first option is probable easier.So my initial question arose when trying to complete the 10 gauge leg feeding the contractor and led 1. Now that I see the led 1 portion can be of smaller gauge, how do you execute this? I'm assuming running 14 gauge back to the terminal bar. Sorry for the noob questions, obviously don't want to use the wrong wire

EDIT: There are many branch points shown in nets in the diagram. None of these should actually be wired as splices in the middle of other wires. All wires should terminate at a screw or connector terminal.

And, as Augie noted, you don't even need 14 G for most of the other wiring. All wires carrying the pump current should probably be 14 G, but all of the control circuit wiring could be 18 G.

The way to figure out how much current a wire needs is to trace the current flow to each load device, and then size the wire carrying the load to that device for the required current. In a branched net, not all branches carry the same current, but they do carry the same voltage.

EDIT: Given your apparent unfamiliarity with electrical circuits (as indicated by the level of questions you asked), you should get an electrician, or some other person you trust who has electrical experience, to check your work before powering anything up.

Brew on

sethlovex

Well-Known Member

- Joined

- Jan 25, 2013

- Messages

- 189

- Reaction score

- 15

All this helps tremendously, thanks everyone. And don't worry Doug, my cousin is a licensed electrician and is installing the spa panel and double checkng everything for me. I have zero experience with these industrial type panels but am quite capable with household wiring.

BlkWater_brewer

Well-Known Member

All three pids, timer, amp meter and all my LEDs are all powered off a single pair of 16 or 18g (cant remember) wires protected by a single 1/2a fuse..... That's right all this stuff draws less that 1/2a combined! I can't help but laugh when I see all these pictures with 12 and 14 gauge wiring running to these things.... pids actually have small DC power supplies in them and run off 24v internally from what I've read... even 18g is technically overkill for the amps draw...

True - the PID's require no more than telephone type wire (22 or 26 gauge) except for the main power lead which is I think 18 by spec. In all actuality people use THHN wire from Home Depot because it is readily available - not because it is the proper wire for the application. It will work fine, it's just cumbersome.

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 11

- Views

- 1K