I've been getting a lot of great ideas and inspiration from other people's build threads, so I thought I'd start my own. I'm building a recirculating eBIAB based off the one from high gravity brewing, with a few modifications. I'm hoping to be able to do 10 gallon full volume mash batches. I started off with a Concorde 80 quart stainless kettle. This is an awesome kettle for the price. I drilled it out with step bits chucked in a stud and joist drill (extremely high torque). I'm glad I didn't spend money on chassis punches, because the holes came out just fine with my $10 HF bits.

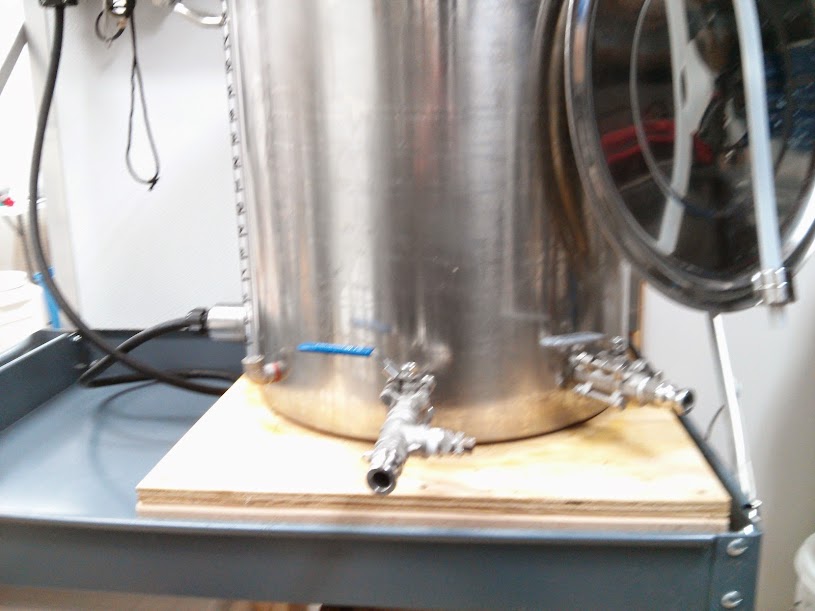

After deburring the holes and giving the kettle a quick bath in some oxyclean, I started installing my fittings. I'm going completely weldless. I'm using a Camco 5500W element, a sight glass and element enclosure from brewhardware, a side pickup from bargainfittings, and a magnesium RV water heater anode. In hindsight, I wish I'd sprung for the all stainless element from brewmation, but we'll see if I have any problems with element rust. I'll be recirculating through a camlock bulkhead in the lid. Here is the kettle getting ready for a leak test/sight glass calibration (please ignore the messy garage)

Here is a view from the inside of the kettle. If you look closely, you'll notice I installed the sight glass wrong :smack: I'll be taking the sight glass off to install the markers after calibration anyway.

After deburring the holes and giving the kettle a quick bath in some oxyclean, I started installing my fittings. I'm going completely weldless. I'm using a Camco 5500W element, a sight glass and element enclosure from brewhardware, a side pickup from bargainfittings, and a magnesium RV water heater anode. In hindsight, I wish I'd sprung for the all stainless element from brewmation, but we'll see if I have any problems with element rust. I'll be recirculating through a camlock bulkhead in the lid. Here is the kettle getting ready for a leak test/sight glass calibration (please ignore the messy garage)

Here is a view from the inside of the kettle. If you look closely, you'll notice I installed the sight glass wrong :smack: I'll be taking the sight glass off to install the markers after calibration anyway.