Glock

Member

- Joined

- Sep 18, 2013

- Messages

- 24

- Reaction score

- 0

Hello All,

Been stalking this forum for nearly 3 years since I began brewing and it's been a great help. I now need to make my first post.

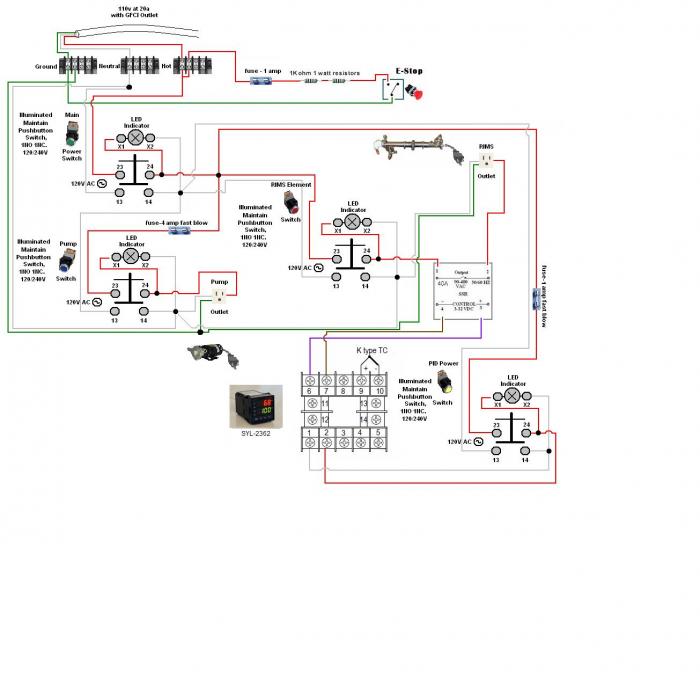

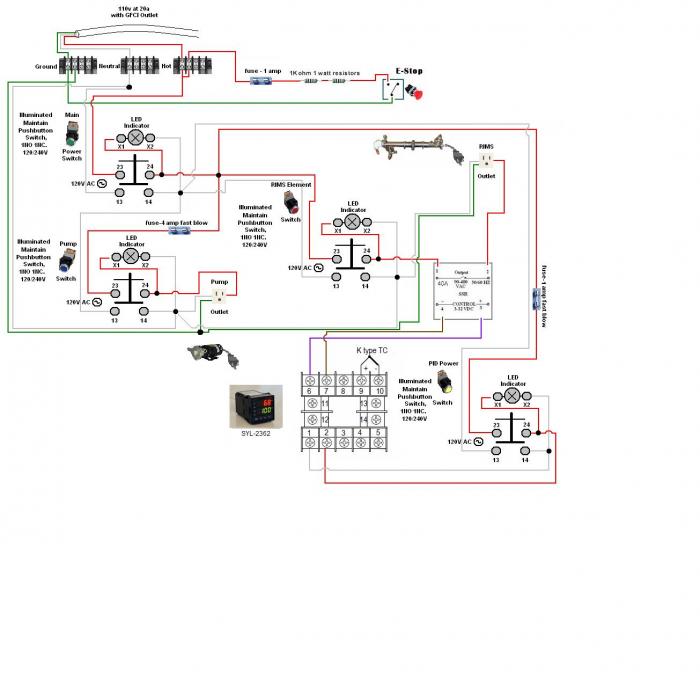

Im almost done creating a 2-tier system with one pump, a RIMS tube, and BK operated by propane. However I need help creating the brain. I got a ton of information from the numerous wiring diagrams and thought I had mine nailed down but got stumped on the light-up push button switches I decided to purchase

Basically I'm trying to have one switch allow power to the rest of the elements in the panel. The RIMS tube will be used to maintain mash temp and I have a single pump that I'll need to run independently for transfer. I added a switch for the PID just because. Im mostly getting confused on the neutral returns to the lights. But I have many other questions that will put my mind at ease if I did it correctly.

So my question is if my wiring diagram is correct?

Am I using the right kind of switches?

Will the Main Power Switch illuminate once closed without any other switch closed?

Does PID wiring look correct to power the RIMS tube outlet element on/off when needed?

Are fuses in right spot/right kind?

Will E-Stop trip GFCI?

Any other glaring problems with the diagram?

I hope I explained what Im trying to do well enough. Thanks for the help.

Been stalking this forum for nearly 3 years since I began brewing and it's been a great help. I now need to make my first post.

Im almost done creating a 2-tier system with one pump, a RIMS tube, and BK operated by propane. However I need help creating the brain. I got a ton of information from the numerous wiring diagrams and thought I had mine nailed down but got stumped on the light-up push button switches I decided to purchase

Basically I'm trying to have one switch allow power to the rest of the elements in the panel. The RIMS tube will be used to maintain mash temp and I have a single pump that I'll need to run independently for transfer. I added a switch for the PID just because. Im mostly getting confused on the neutral returns to the lights. But I have many other questions that will put my mind at ease if I did it correctly.

So my question is if my wiring diagram is correct?

Am I using the right kind of switches?

Will the Main Power Switch illuminate once closed without any other switch closed?

Does PID wiring look correct to power the RIMS tube outlet element on/off when needed?

Are fuses in right spot/right kind?

Will E-Stop trip GFCI?

Any other glaring problems with the diagram?

I hope I explained what Im trying to do well enough. Thanks for the help.