Bigscience

Well-Known Member

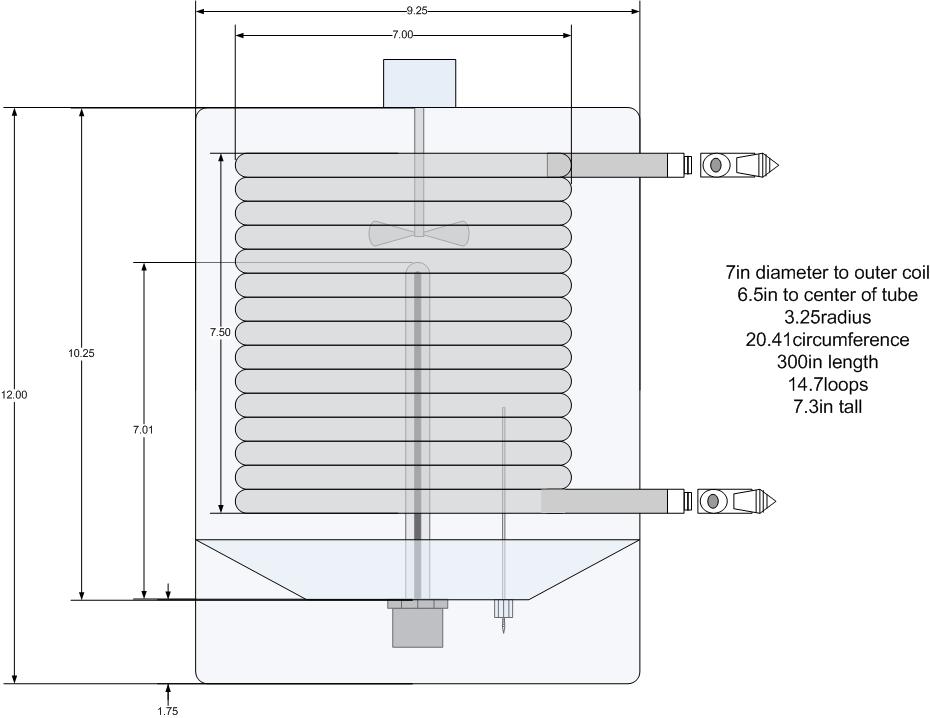

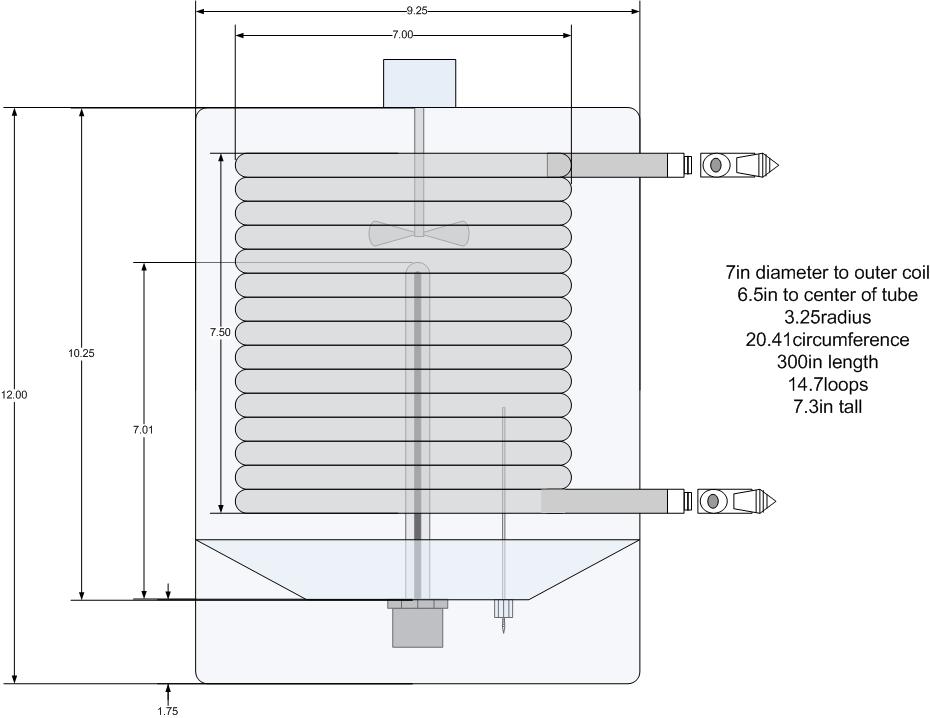

After many years with a HLT heat exchanger, I want to build a separate, small volume heat exchanger. I have a 5 gal sanke I was thinking could be cut down to about half the size and then weld a coil in through the sides for ease of draining. For flow rate, I wanted to use 1/2" stainless tube, about 25' of it for good exchange. The diameter of the keg is 9.25" so I was thinking a 7" diameter coil would leave enough room for couplers/welding.

Here are the questions:

Can you bend 1/2" tube in a 7" diameter coil? I'm not assuming I can do this by hand but could a machine shop do it? I have a nice CFC that's in a 6.25" coil but that has 3/8 tube inside it so maybe that's why it didn't crush.

I emailed nybrewsupply and they said they could do it with 3/8" but didn't think it would work with 1/2". I really don't want to do 3/8" for flow reasons. Does anyone use a 3/8" coil and if so, how does it work out?

For the coupling through the keg wall, I was thinking about doing something like below BUT since it will be so tight, I was thinking about welding the elbows to the tube and then welding the elbow to the keg wall. Any other ideas on how to pull this off?

Thanks in advance for the help.

Here are the questions:

Can you bend 1/2" tube in a 7" diameter coil? I'm not assuming I can do this by hand but could a machine shop do it? I have a nice CFC that's in a 6.25" coil but that has 3/8 tube inside it so maybe that's why it didn't crush.

I emailed nybrewsupply and they said they could do it with 3/8" but didn't think it would work with 1/2". I really don't want to do 3/8" for flow reasons. Does anyone use a 3/8" coil and if so, how does it work out?

For the coupling through the keg wall, I was thinking about doing something like below BUT since it will be so tight, I was thinking about welding the elbows to the tube and then welding the elbow to the keg wall. Any other ideas on how to pull this off?

Thanks in advance for the help.