Cool now I don't have to worry about you man!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your panel

- Thread starter Jps101

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Kal, your system is the gold standard of electric brewing, and without your inspiration, as well as your published design, I would still be trying to get 6 gallons of water to boil on a stove. All you guys on this forum are rock stars to me, and I have been following for years picking up tips. Thanks to you all.

+1 -- well said!

kal

Well-Known Member

That's very kind guys but my design (both panel and brewing process) is simple a mash up of all sorts of things I've researched over the years from all over the 'net - both here at HBT and elsewhere. There's definitely 100's of different people responsible for the types of panels we're seeing today. I like to think of it as a big community / open source endeavour that we've helped with in one way or another.Kal, your system is the gold standard of electric brewing, and without your inspiration, as well as your published design, I would still be trying to get 6 gallons of water to boil on a stove.

Happy brewing!

Kal

NoneRequired

Member

My scaled down kal clone

Would love to see your schematic for this, it's exactly what was planning for my BIAB setup.

View attachment ImageUploadedByHome Brew1450835021.461302.jpgMy current control box inside. Pretty much out of things to add (and space)!

My current control box inside. Pretty much out of things to add (and space)!

How about a soft ice cream machine?

ccfoo242

Well-Known Member

View attachment 324607My current control box inside. Pretty much out of things to add (and space)!

You should post that to the cableporn subreddit https://www.reddit.com/r/cableporn

rockinmarty

Big Member

Would love to see your schematic for this, it's exactly what was planning for my BIAB setup.

Check post 152

rockinmarty

Big Member

Dup

abarker8541

Well-Known Member

My new controller

rockinmarty

Big Member

abarker8541

Well-Known Member

In all honesty i followed p-j's schematic from hbt. Its pretty simple.

applescrap

Be the ball!

View attachment 324607My current control box inside. Pretty much out of things to add (and space)!

Wow

View attachment 324607My current control box inside. Pretty much out of things to add (and space)!

I wish I went this route with the wire management channels. Looks really nice. Great job.

And DAMN, that's a lot of I/O's!

Thanks!

applescrap

Be the ball!

Genius really, what does it do

View attachment 324607My current control box inside. Pretty much out of things to add (and space)!

BrunDog -- if you're willing and ever get a chance (or maybe I've missed the thread?), I'd be very interested to see/read a full rundown on your controller build.

That thing looks sweet!

My system is in the build thread linked in my signature. If you are asking about control panel specifics, I can post up more details - let me know.

LarMoeCur

Well-Known Member

BrunDog -- if you're willing and ever get a chance (or maybe I've missed the thread?), I'd be very interested to see/read a full rundown on your controller build.

That thing looks sweet!

I second that. We need a full rundown. Your wire management makes my panel look like a birds nest.

My system is in the build thread linked in my signature. If you are asking about control panel specifics, I can post up more details - let me know.

Yes. Control panel specifics

BeerMonkey_Brewery

Member

- Joined

- May 27, 2014

- Messages

- 10

- Reaction score

- 1

My updated panel. 3phase, 400v/16A (I live in Sweden, so the electric system differs from U.S)

3 SSR with quite small heatsinks, but 2 fans makes sure that they stay cool.

Dual outlet, one for HLT and one for the boiler. The on/on switch is used to choose if the PID or the "boil controller" triggers the SSRs.

Indivual Volt/Amp meters (one per phase)

3 SSR with quite small heatsinks, but 2 fans makes sure that they stay cool.

Dual outlet, one for HLT and one for the boiler. The on/on switch is used to choose if the PID or the "boil controller" triggers the SSRs.

Indivual Volt/Amp meters (one per phase)

My updated panel. 3phase, 400v/16A (I live in Sweden, so the electric system differs from U.S)

3 SSR with quite small heatsinks, but 2 fans makes sure that they stay cool.

Dual outlet, one for HLT and one for the boiler. The on/on switch is used to choose if the PID or the "boil controller" triggers the SSRs.

Indivual Volt/Amp meters (one per phase)

Nice work on the build. I just added the same ON/ON switch and auber Digital SSR Power Regulator to my panel. I'll be using it for the first time tomorrow. I believe the ability to switch control from the PID to manual knob adjustment will be a huge improvement in boil control.

BeerMonkey_Brewery

Member

- Joined

- May 27, 2014

- Messages

- 10

- Reaction score

- 1

Nice work on the build. I just added the same ON/ON switch and auber Digital SSR Power Regulator to my panel. I'll be using it for the first time tomorrow. I believe the ability to switch control from the PID to manual knob adjustment will be a huge improvement in boil control.

Thx. And your right, it's a Digital SSR Power Regulator

BeerMonkey_Brewery

Member

- Joined

- May 27, 2014

- Messages

- 10

- Reaction score

- 1

Nice work on the build. I just added the same ON/ON switch and auber Digital SSR Power Regulator to my panel. I'll be using it for the first time tomorrow. I believe the ability to switch control from the PID to manual knob adjustment will be a huge improvement in boil control.

Thx!

And your right, it's a Digital SSR Power Regulator

augiedoggy

Well-Known Member

Is it an auberins brand one or some other by chance?Thx!

And your right, it's a Digital SSR Power Regulator

You Would think by now auberins would see there is enough demand to design a pid where the built in manual pwm/regulator would be easier to use and switch back and forth from pid mode to.. So many with the auber pids seem to install a secondary manual control rather than use the one built in the pid.

I need to read more about this power regulator thingamajig

Is it an auberins brand one or some other by chance?

You Would think by now auberins would see there is enough demand to design a pid where the built in manual pwm/regulator would be easier to use and switch back and forth from pid mode to.. So many with the auber pids seem to install a secondary manual control rather than use the one built in the pid.

It is from Auberins, and yes it would be cool if they would combine it with a PID. I used mine yesterday for the first time and it worked fantastic. I use the PID to bring the BK to the brink of a boil and then switch over to the power controller. I had been using a 4500 watt element which worked fairly well at full power to boil 12 or 13 gallons, but was a bit much for smaller batches and a little under powered for larger batches. I always found it to be a pain to use manual mode on the PID and boil overs can happen quickly. Now I went back to using a 5500w element, which heats a little faster, but can be easily controlled with the new power controller. It cycles the power much faster than the PID for a very even boil and power draw. It also uses the same SSR (not a variable SSR) as the PID. All that was required was AC power and a DPDT switch to switch the SSR output of the PID and the Power Controller. The ONLY thing that could be a little annoying about the set up is that the controller turns my light that shows my element firing into a strobe light. It didn't bother me as much as I thought it might though, I had a piece of tape handy just in case but never used it. Here's a pic of the controller installed...

- Joined

- Dec 5, 2007

- Messages

- 1,719

- Reaction score

- 759

My panel box is a work in progress but I did get the holes cut and drilled and installed the controls and labels today. The panel will eventually run a Honeywell gas valve connected to a natural gas burner for my HLT which contains a HERMS coil. The panel will also control both my pumps.

I wasn't originally going to include a timer but Kal's write-up convinced me otherwise, though I bought a cheaper one than what he used..

I wasn't originally going to include a timer but Kal's write-up convinced me otherwise, though I bought a cheaper one than what he used..

Nimbus3000

Well-Known Member

- Joined

- Feb 14, 2015

- Messages

- 61

- Reaction score

- 21

First test today. Magic blue smoke was not released. No temp sensors attached yet. Only thing that confused me was that when I turn on the boil kettle and hlt alarm switches the alarm led has a dim glow. When I turn on the mash tun and timer alarms the led does not glow. I have them wired per the diagrams on the Electric Brewery site. Any ideas why two of the four alarms would be feeding low power to the led?

First test today. Magic blue smoke was not released. No temp sensors attached yet. Only thing that confused me was that when I turn on the boil kettle and hlt alarm switches the alarm led has a dim glow. When I turn on the mash tun and timer alarms the led does not glow. I have them wired per the diagrams on the Electric Brewery site. Any ideas why two of the four alarms would be feeding low power to the led?

That looks awesome!

Nimbus3000

Well-Known Member

- Joined

- Feb 14, 2015

- Messages

- 61

- Reaction score

- 21

Figured out the dim led. Feel kind of dumb now. I switched a red lens onto a yellow led.

sensortech

Well-Known Member

Figured out the dim led. Feel kind of dumb now. I switched a red lens onto a yellow led.

Ha! I'm not alone. Did the same thing.

augiedoggy

Well-Known Member

Lol same here..

bellinmi88

Well-Known Member

Hey MB, what plate chiller model# is that... its a MONSTER!

applescrap

Be the ball!

Rims

Slick system! Love the stickers. If used cell attach camera direct photo try sideways

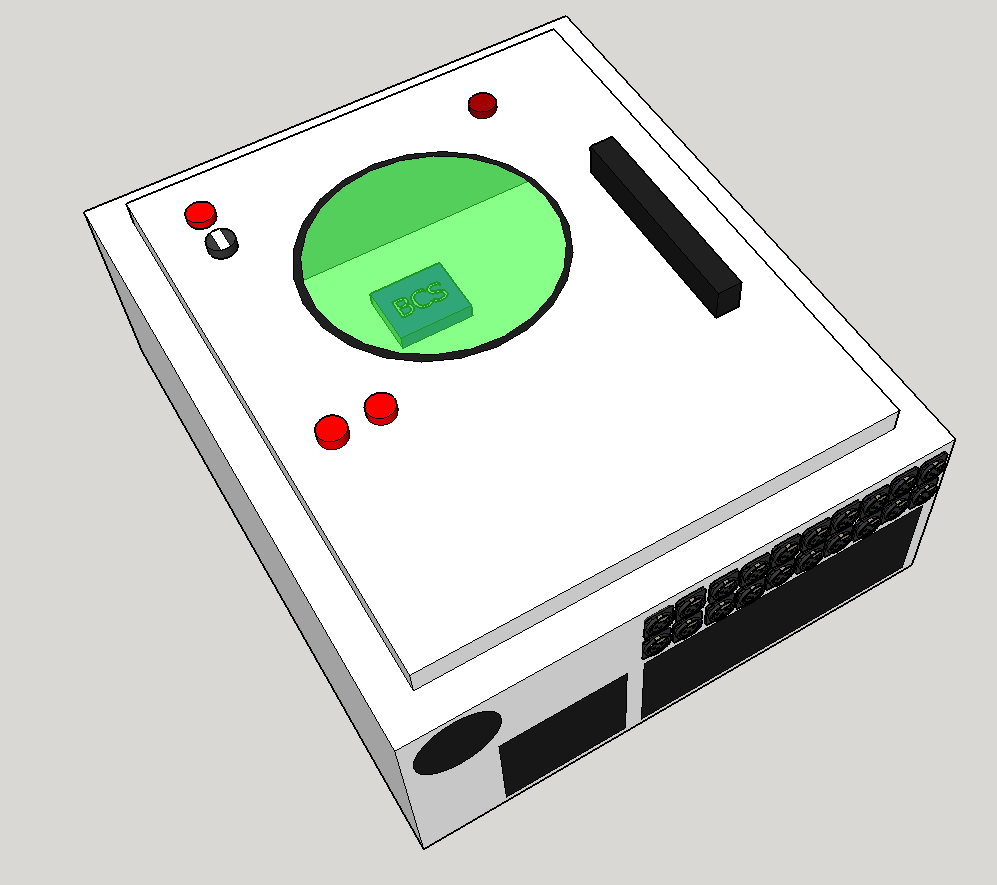

This is my latest system Im building, should test fire it up next week. Its all wired up and continuity tested, and BCS460 is all connected and functioning so I'm hoping for a smooth wet test.

Three 809 pumps, two 5500 watt elements an one 220vac march AC4 pump for CIP, I added two seven segment displays, and manual override push buttons controlling the HTL/MLT and MTL/BK pumps for priming.

really looking forward to brewing again.

Three 809 pumps, two 5500 watt elements an one 220vac march AC4 pump for CIP, I added two seven segment displays, and manual override push buttons controlling the HTL/MLT and MTL/BK pumps for priming.

really looking forward to brewing again.

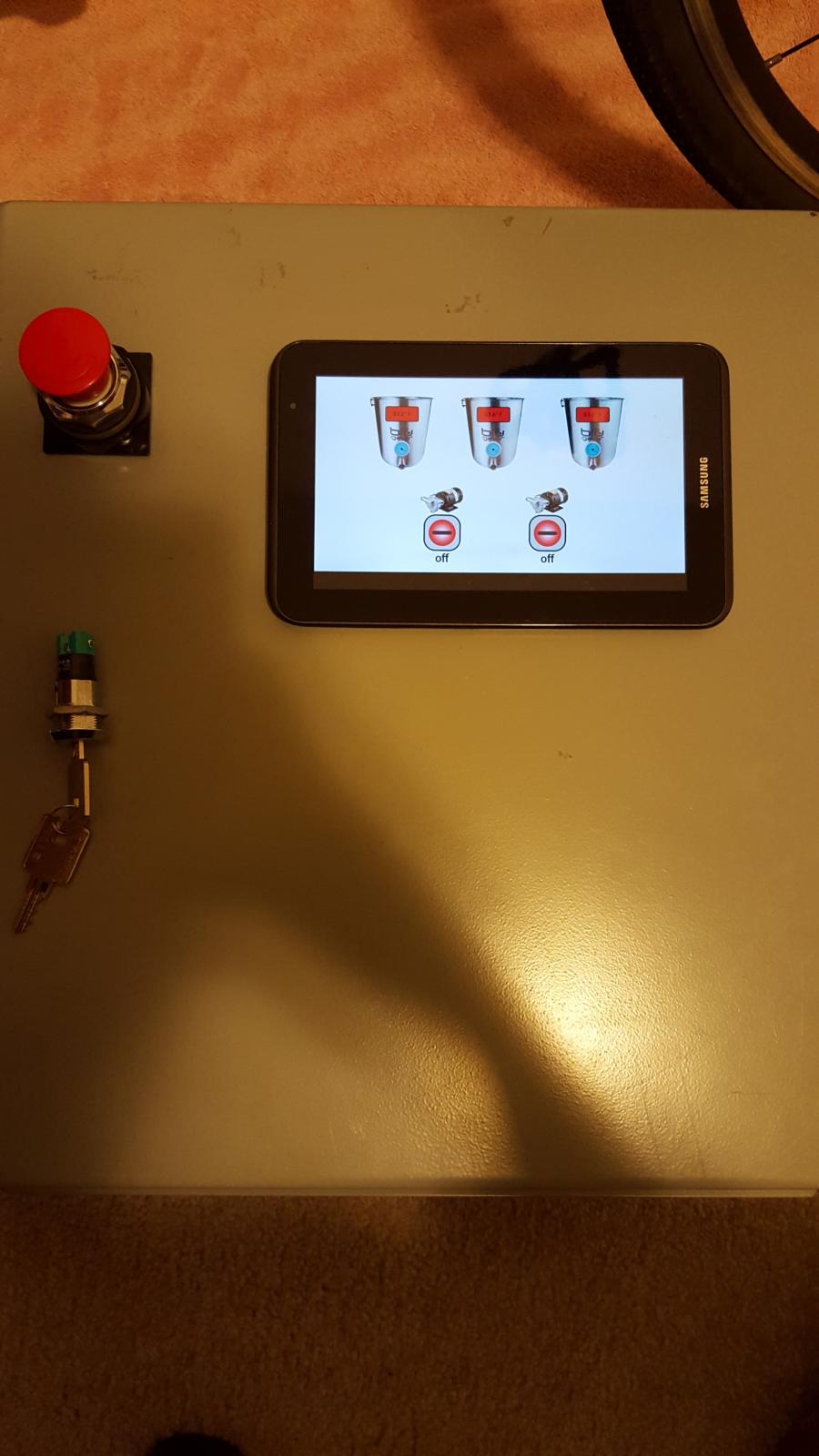

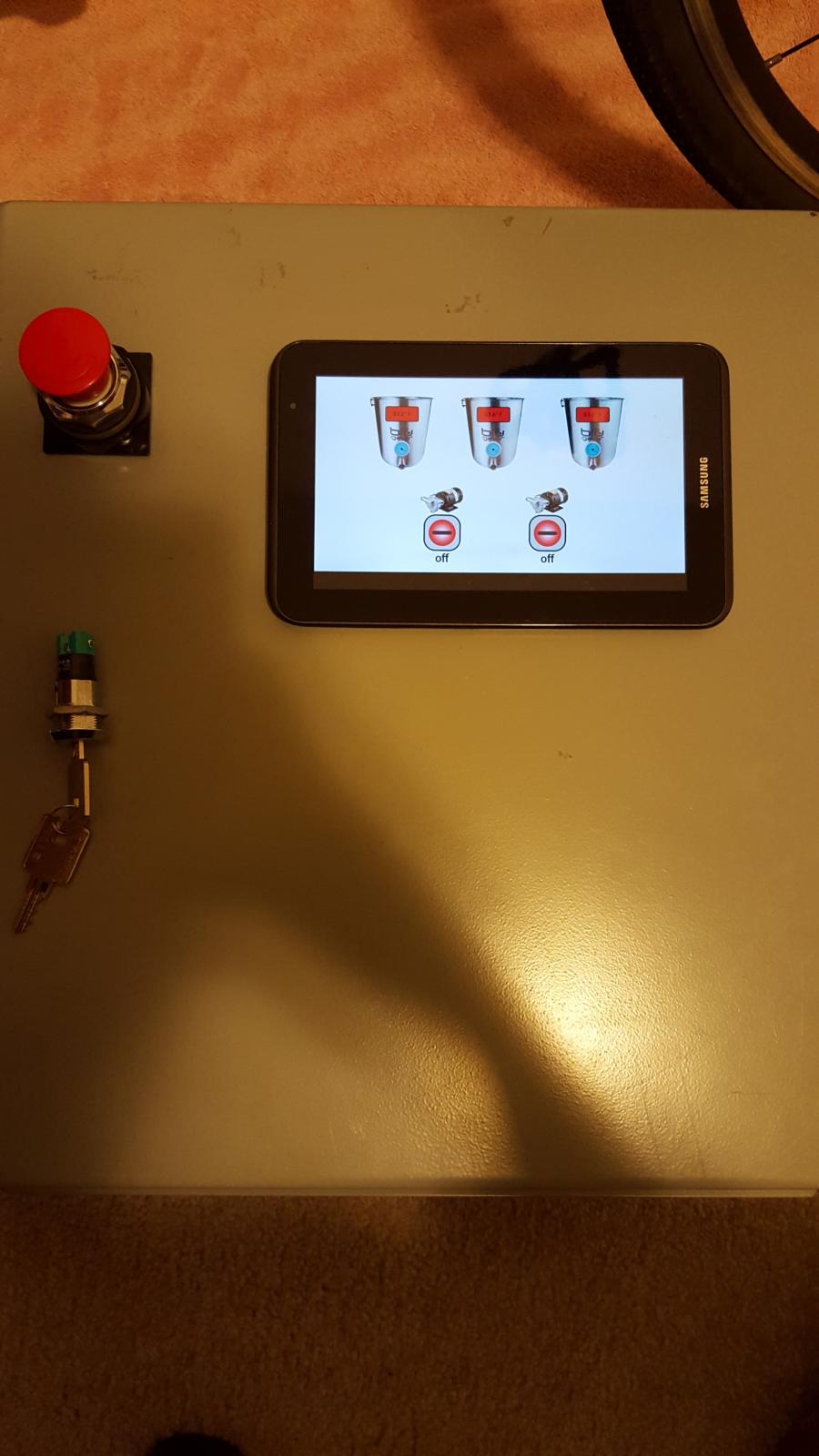

Not finished by any means, but here's the current status of my panel. Only E-stop, keyswitch, receptacles and antenna will be visible on the outside. All of the controls/indicators will be on the HMI.

Similar threads

- Replies

- 10

- Views

- 673

- Replies

- 2

- Views

- 669

- Replies

- 4

- Views

- 172