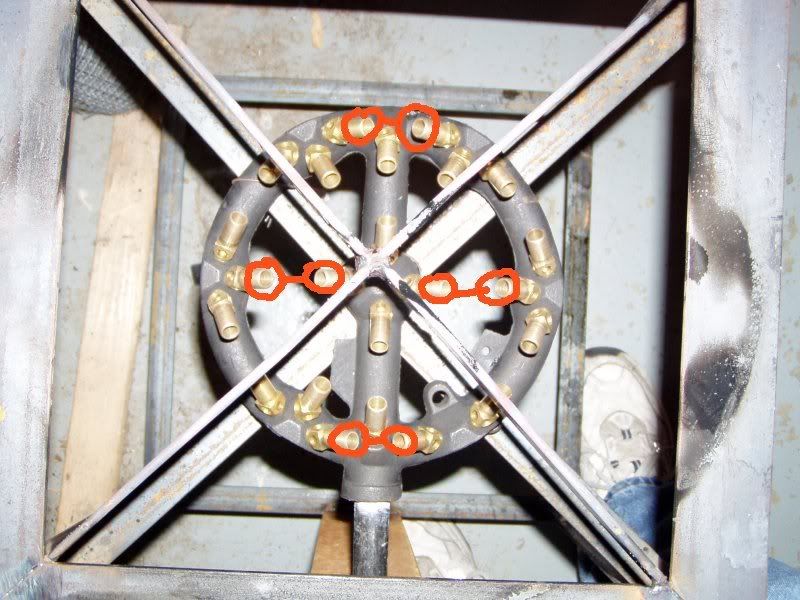

I brewed with a new rig that I picked up a little while ago. It has two of these 23 tip jet burners set up for propane. A few days before brew day, I did a burner test and it seemed to me that with all 23 tips running, it was way too intense. The burner frame was glowing, the bottom of the keggle HLT was glowing, the wood on my deck smelled like it was about to go up in flames. In this picture, it looks like it's melting the side of the house.

With the 0-30 psi regulator, I was able to adjust it somewhat. The lowest level I could run the burner while keeping a nice blue flame seemed to be about 60% of the maximum...not very low. Even at that level, it was spilling heat around the keggle. My sight gauge was bubbling and boiling over, and it looked like the heat was actually starting to melt the plastic a bit. Way hot. I didn't like running it lower than that ~60% of max because the flame would start to get a bit more yellow than I'd like.

It definitely heated the water quickly, but I felt like I was wasting a ton of heat around the sides of the keggle and such. The branches on my mulberry tree about six feet above the top of the keggle are quite singed and crispy looking.

Also, the burner was loud enough that I wasn't able to hold a conversation with anyone on the back porch. We had to step inside the house to talk instead of yell.

I decided that I'd plug 8 of the tips for the BK burner and leave the HLT burner as-is. Down to 15 tips, the output was much more reasonable and it easily kept a rolling boil on just under 8 gallons (pre-boil volume.) I still had it adjusted towards the low end of the range on the regulator, but at one point I adjusted slightly too low and ended up reducing the volume to an active simmer instead of a boil. So, the adjustability was there somewhat. I'd say that during the course of the boil, I ran the burner in the range of 60-75% of max. And I put square patio pavers beneath the burner to protect the wood on the deck. That worked out well.

I also managed to singe a few hairs right at my hairline while lighting the burner. I really need to get one of those extended grill lighters...or at least be more careful where I'm sticking my face.

Not a flaw of the burner, just me being stupid.

Anyway, I just switched my HLT to electric so I'm going with a 1 burner setup (BK.) I'll stick with an 11 or 13 tip setup depending on what works on my next brew day.

In hindsight, I wouldn't say that I'd pick this burner over others without doing a little more research. But, it's what I've got and I'm sure I'll be able to make it work.

Not a flaw of the burner, just me being stupid.

Not a flaw of the burner, just me being stupid.