Schnitzengiggle

Well-Known Member

I recently ordered all of my supplies from kegconnection, and although my regulator guages were damaged during shipping, they quickly sent me a new pair of Taprite guages with no questions asked.

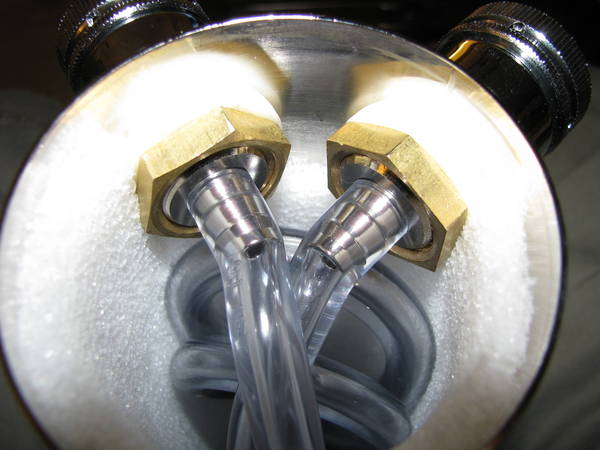

Having said that, I am going to be assembling my kegerator this weekend, and I cracked my tower open tonight to replace my 5' beer lines w/10' lines and discovered this:

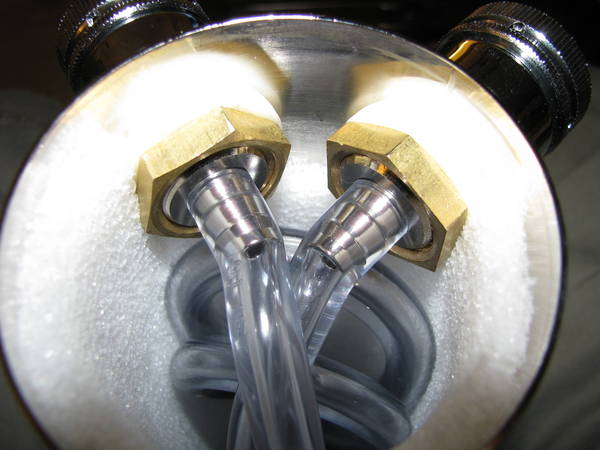

Now I am completely new to kegging and I try to do my research, but those look like standard tailpieces to me, not elbow style tower tailpieces, such as these:

Another fellow HBT member posted this pic back in February of this year.

I am certain Taprite changes things periodically, but is this right?

If you look at the images of my draft tower, the hoses aren't even straight at the connecton, is that going to create turbulence leading to excessive foaming?

It is my understanding that the elbow style tailpieces are "tower tailpieces" and the "straight tailpieces" (like what are currently on my draft tower) are for straight connections like through a refridgerator door and such.

I could be wrong, I am new to kegging, but before I get to tinkering, should I ask for the elbow pieces?

Will the slight curvature of the hose at the connection lead to exccesive foaming?

Finally, is this completely wrong? Should there be elbow style tailpieces in the tower?

Any help/information/advice would be extremely apprciated. Thank you.

Having said that, I am going to be assembling my kegerator this weekend, and I cracked my tower open tonight to replace my 5' beer lines w/10' lines and discovered this:

Now I am completely new to kegging and I try to do my research, but those look like standard tailpieces to me, not elbow style tower tailpieces, such as these:

Another fellow HBT member posted this pic back in February of this year.

I am certain Taprite changes things periodically, but is this right?

If you look at the images of my draft tower, the hoses aren't even straight at the connecton, is that going to create turbulence leading to excessive foaming?

It is my understanding that the elbow style tailpieces are "tower tailpieces" and the "straight tailpieces" (like what are currently on my draft tower) are for straight connections like through a refridgerator door and such.

I could be wrong, I am new to kegging, but before I get to tinkering, should I ask for the elbow pieces?

Will the slight curvature of the hose at the connection lead to exccesive foaming?

Finally, is this completely wrong? Should there be elbow style tailpieces in the tower?

Any help/information/advice would be extremely apprciated. Thank you.