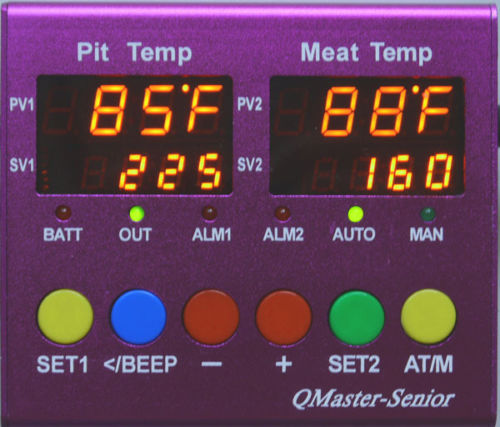

I haven't seen anything on the inter-web about modifying the “The Good-One Marshall” with a temperature controller using a PID, so I'll post my project here so others may benefit from.

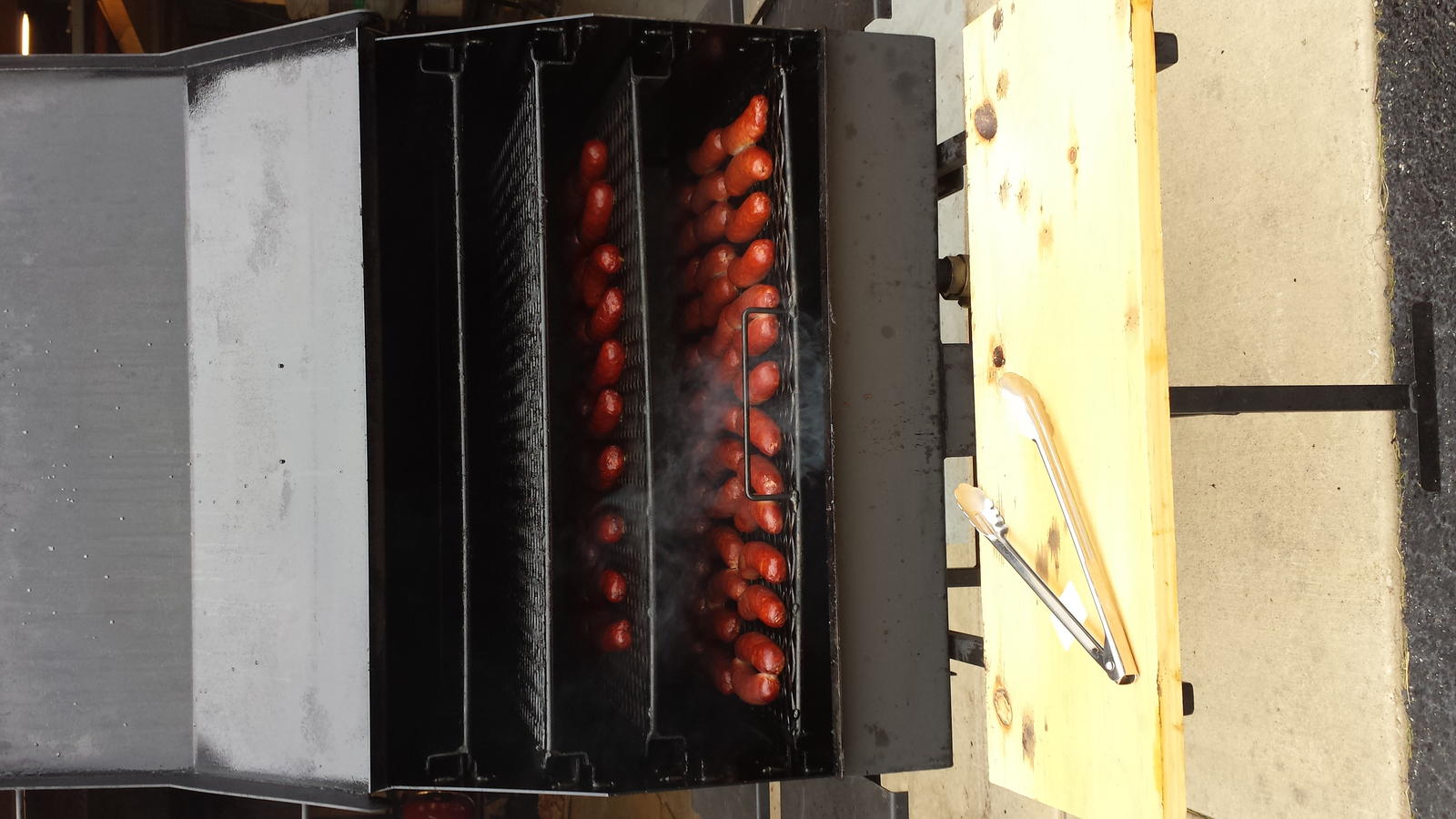

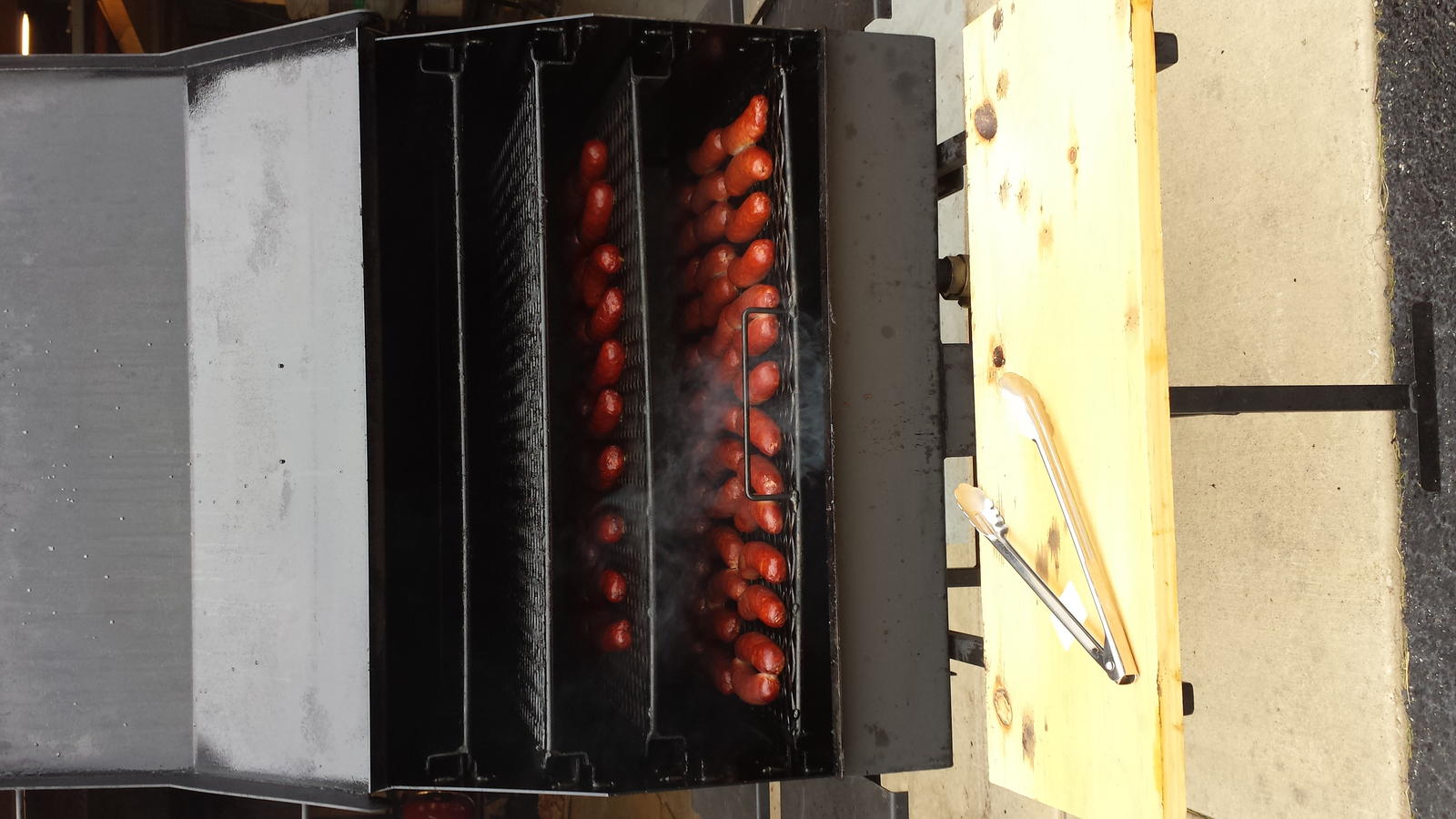

I purchased a used The Good-One Marshall Smoker/grill off Craigslist back in August of this year. It is a great smoker and can smoke 1 to 26 slabs of baby-back ribs, or 6 Butts plus 6 Briskets at one time. It really is a neat piece of equipment. If you been following my Brewery build you will know I'm an all-Electric guy and love the control of the PID's on my "Kal Clone" gives me to ensure repeatable and consistent results every time.

So I was smoking some ribs for the first time and noticed I had to babysit the smoker so the heat didn't runaway on me and destroy my meat. I was aware that there are smoker/grill controllers out there that I noticed while looking for the right smoker to meet my needs. But my search for one that would adapt/fit a 3 inlet Marshall was not working out. I decide to make my own manifold header to port forced air when needed to all three inlets. The following is how I went about doing it. Hope others find it useful.

The inlet ports are just under 3 inches diameter, so I figured I’d need something that would cover them and found 3 inch galvanized stove pine from Menards may work so I went and picked up a few parts I felt would work.

• One 24 inch long by 3” pipe

• One 3 “ 90 degree adjustable elbow

• Two 3” saddle tee’s

• One 3" end cap

• One 36” X 3/8” threaded rod to make attaching bolts

• Three 3/8” connecting nuts (Long nuts used to connect two 3/8” bolts together)

• Three 3/8” wing nuts and large 3/8” fender washers

• Sheet metal screws to hold it all together

The centers of the inlets I found to be 9” centers. I found a piece of scrap 2x4 and laid out 3 marks with 9 inch centers and then made three 3” circles as my templet.

I trimmed the 24” X 3” tube to 20” and put the plug in to protect me from the sharp edges.

I installed the 90 Degree adjustable elbow and then set the 3” saddle tees on the templet to line thing up on the 9” centers. Once I had everything lined up, I install a few screws to hold it together to dry fit it and see if everything lined up and it did.

I then marked the inside of the tee where it need to be cut out and removed the screws and cut the holes using a drill and a pair of tin snips.

Put the screws back in and did another dry fit and was convinced I had it so I went ahead and screwed it all together.

I place the manifold back on the templet and transfer the 9” center lines to the top for the 3/8” blots and then drilled them.

I then took the 3 fender washers and put them in the vise to bend them to the contour of the 3” pipe for a snug fit and installed.

I installed the manifold and the blower fan and I’m waiting to test it shortly.

Hope this helps someone, castermmt

I purchased a used The Good-One Marshall Smoker/grill off Craigslist back in August of this year. It is a great smoker and can smoke 1 to 26 slabs of baby-back ribs, or 6 Butts plus 6 Briskets at one time. It really is a neat piece of equipment. If you been following my Brewery build you will know I'm an all-Electric guy and love the control of the PID's on my "Kal Clone" gives me to ensure repeatable and consistent results every time.

So I was smoking some ribs for the first time and noticed I had to babysit the smoker so the heat didn't runaway on me and destroy my meat. I was aware that there are smoker/grill controllers out there that I noticed while looking for the right smoker to meet my needs. But my search for one that would adapt/fit a 3 inlet Marshall was not working out. I decide to make my own manifold header to port forced air when needed to all three inlets. The following is how I went about doing it. Hope others find it useful.

The inlet ports are just under 3 inches diameter, so I figured I’d need something that would cover them and found 3 inch galvanized stove pine from Menards may work so I went and picked up a few parts I felt would work.

• One 24 inch long by 3” pipe

• One 3 “ 90 degree adjustable elbow

• Two 3” saddle tee’s

• One 3" end cap

• One 36” X 3/8” threaded rod to make attaching bolts

• Three 3/8” connecting nuts (Long nuts used to connect two 3/8” bolts together)

• Three 3/8” wing nuts and large 3/8” fender washers

• Sheet metal screws to hold it all together

The centers of the inlets I found to be 9” centers. I found a piece of scrap 2x4 and laid out 3 marks with 9 inch centers and then made three 3” circles as my templet.

I trimmed the 24” X 3” tube to 20” and put the plug in to protect me from the sharp edges.

I installed the 90 Degree adjustable elbow and then set the 3” saddle tees on the templet to line thing up on the 9” centers. Once I had everything lined up, I install a few screws to hold it together to dry fit it and see if everything lined up and it did.

I then marked the inside of the tee where it need to be cut out and removed the screws and cut the holes using a drill and a pair of tin snips.

Put the screws back in and did another dry fit and was convinced I had it so I went ahead and screwed it all together.

I place the manifold back on the templet and transfer the 9” center lines to the top for the 3/8” blots and then drilled them.

I then took the 3 fender washers and put them in the vise to bend them to the contour of the 3” pipe for a snug fit and installed.

I installed the manifold and the blower fan and I’m waiting to test it shortly.

Hope this helps someone, castermmt