Got the plumbing Hardware from Bobby M at BrewHardware.com Great deal and fast shipping.

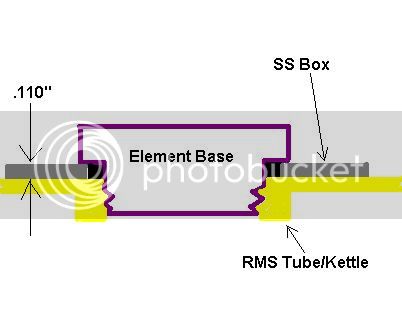

Gave the center tube a polish, and put some serious thought and effort into the electrical box.

Got the SS box tubing from onlinemetals.com. They happen to be right down the street from my work.

Everything you see is stainless except the waterproof strain relief (it's aluminum) and the cord.

I also made a second electrical box for the HLT.

Can't wait to try it out tomorrow.

Gave the center tube a polish, and put some serious thought and effort into the electrical box.

Got the SS box tubing from onlinemetals.com. They happen to be right down the street from my work.

Everything you see is stainless except the waterproof strain relief (it's aluminum) and the cord.

I also made a second electrical box for the HLT.

Can't wait to try it out tomorrow.