inhousebrew

Well-Known Member

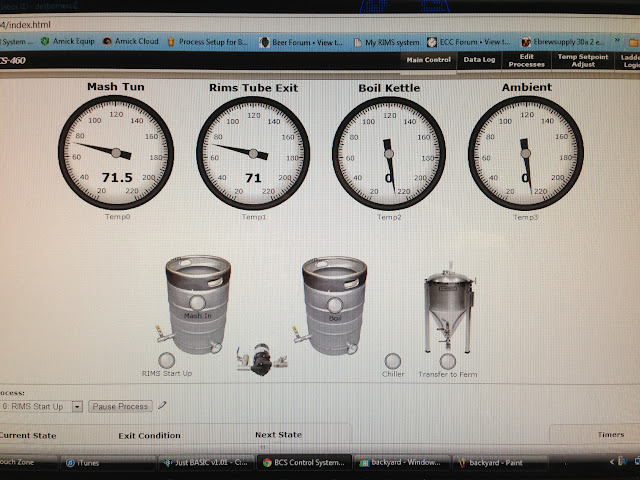

Sweet!

I love it!

I want it!

I need it!

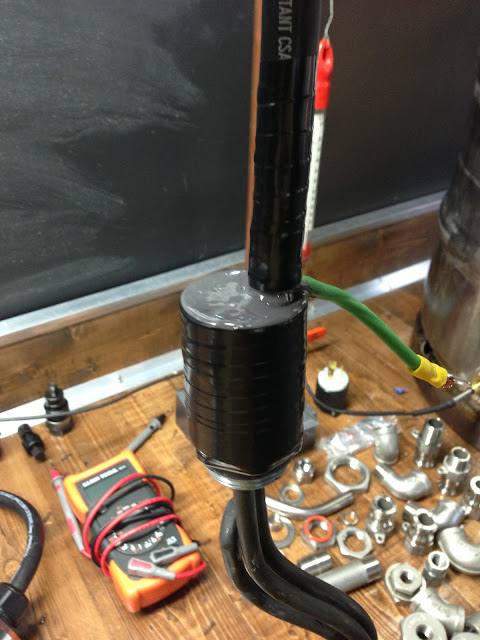

I.....don't even own my own garage or have the money for something so big.

I love it!

I want it!

I need it!

I.....don't even own my own garage or have the money for something so big.