skeeordye11 gave me this charcoal smoker that he didn't want.

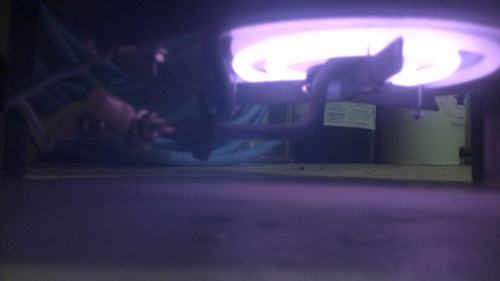

And I decided that it would be a good idea to convert it to electric and use the same panel I control my brewing system with to control the smoker. So, I bought a 6" 1250W element for an electric stove off ebay for $8 and decided to mount it to the bottom of the pan that used to hold coals.

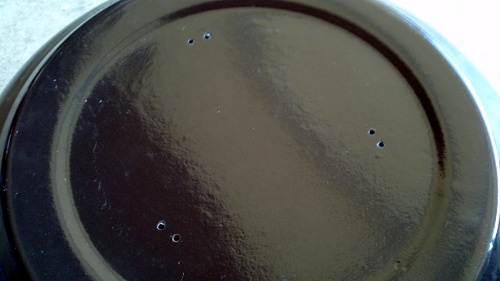

To mount it, I drilled three pairs of small holes in the pan right next to each arm of the "Y" shaped bracket on the burner.

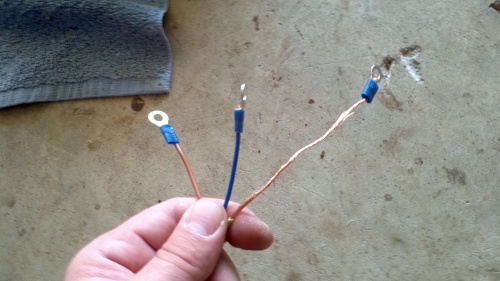

Then I cut some short lenghts of thick copper wire and bent them into a U shape.

From inside the pan, I put each U through one of the sets of holes.

Then I just used those like big-ass twist ties to secure the burner to the bottom of the pan.

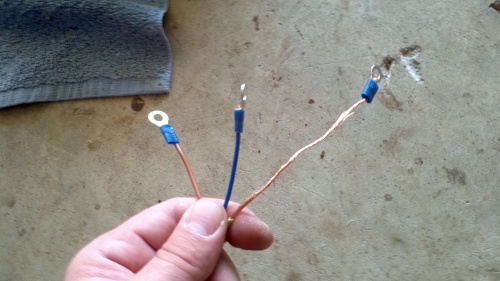

Then came the wiring. I stripped the end of a power cord and put some ring terminals on it.

Then attached those to the burner's leads with some machines screws/nuts/washers. I drilled another hole in the pan and attched the ground wire directly to it (and removed the plastic insulation on the connector since it was doomed to melt anyway). I need to probably replace that ground connection hardware with stainless since it's directly in the pan. These are zinc plated steel at the moment.

And I decided that it would be a good idea to convert it to electric and use the same panel I control my brewing system with to control the smoker. So, I bought a 6" 1250W element for an electric stove off ebay for $8 and decided to mount it to the bottom of the pan that used to hold coals.

To mount it, I drilled three pairs of small holes in the pan right next to each arm of the "Y" shaped bracket on the burner.

Then I cut some short lenghts of thick copper wire and bent them into a U shape.

From inside the pan, I put each U through one of the sets of holes.

Then I just used those like big-ass twist ties to secure the burner to the bottom of the pan.

Then came the wiring. I stripped the end of a power cord and put some ring terminals on it.

Then attached those to the burner's leads with some machines screws/nuts/washers. I drilled another hole in the pan and attched the ground wire directly to it (and removed the plastic insulation on the connector since it was doomed to melt anyway). I need to probably replace that ground connection hardware with stainless since it's directly in the pan. These are zinc plated steel at the moment.