Here is my first build project out of a side-by-side fridge that came with my house. Luckily SWMBO hates it, and for the small price of buying her a new one, I am able to turn this one into my fermentation chamber. It is a Whirlpool model ED22MM1JWRO and is almost as old as I am. Unfortunately, the center divider does not remove, as there is a coolant line that runs through the wall about halfway up. I didn't find this out until I had the center metal stip pulled out - and that wasn't easy.

What follows will be a catalog of my build making two seperate chambers out of the same fridge. I have 2 ebay style temp controllers, one for each side, which will operate the compressor, a heat lamp, and 2 80mm 110v fans. The fans will more air between chambers to help each side regulate temps.

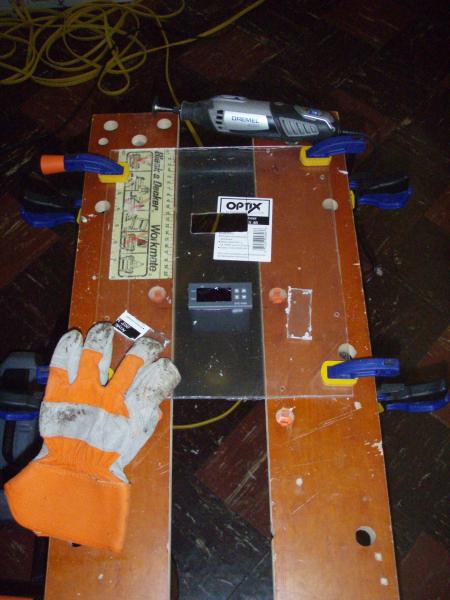

The plan is to place the controllers in the space that formerly held the ice/water dispensing unit. I built the housing for the controllers out of 1x4and as the original liner took up a lot of space in the chamber, I replaced it with .093" acrylic sheeting. The acrylic needed special drill bits for, so I bought a drill press for this and other projects.

What follows will be a catalog of my build making two seperate chambers out of the same fridge. I have 2 ebay style temp controllers, one for each side, which will operate the compressor, a heat lamp, and 2 80mm 110v fans. The fans will more air between chambers to help each side regulate temps.

The plan is to place the controllers in the space that formerly held the ice/water dispensing unit. I built the housing for the controllers out of 1x4and as the original liner took up a lot of space in the chamber, I replaced it with .093" acrylic sheeting. The acrylic needed special drill bits for, so I bought a drill press for this and other projects.