Tiber_Brew,

Ok... It took a little while with the bits and pieces - but - Here is latest diagram. It has the breakers that you ordered and I've also placed pix of your switched. I've changes some of the foot notes as well.

As usual - Click on the image for a full scale drawing.

The full sacle image is set up for printing on a 11" X 17" sheet of paper.

I sure hope this helps you. Please let me know your thoughts.

That looks great, P-J. Nice work!

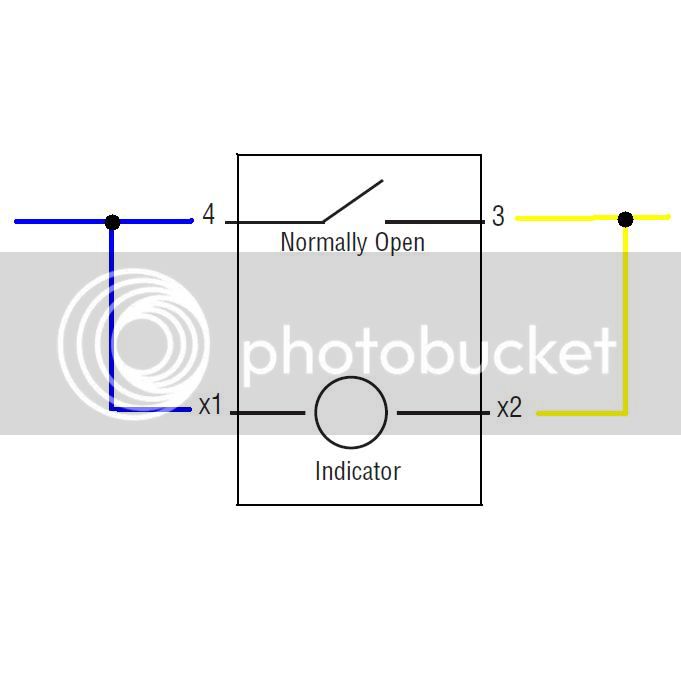

I do have one question about those switches, though. I looked at the datasheet for them and I'm still a little unclear about how to wire them with the indicator. The LED bulb takes the full 120V, so would I just split a line into the X1 and a neutral to the X2?

I tried showing this on your diagram (with my mad MS Paint skills). Take a look at switches 1 & 2. Does that look correct to you?

Here are my MS Paint skills again. The blue is hot, yellow is neutral.

Thanks again. I appreciate all the great help I'm getting here.

TB