armymedic942

Well-Known Member

Hello HBT,

Here are the first pictures of my EHERMS setup. Just finished it last night, now I am in the process of testing it. So far, so good, should be ready for my first all-grain batch by the weekend!!

It is a 3 vessel, single tier system. I used 2 sanke kegs and 1 10gal bayou kettle. I have 2 march 815 pumps (you will notice that 1 of them has a stainless head, because I had an oops while plumbing, requiring me to buy a replacement). The Boil Kettle and HLT each have 5500w electric heating elements installed and are PID controlled. The MLT has an analog thermometer.

I used a stainless steel operating room cart as the stand.

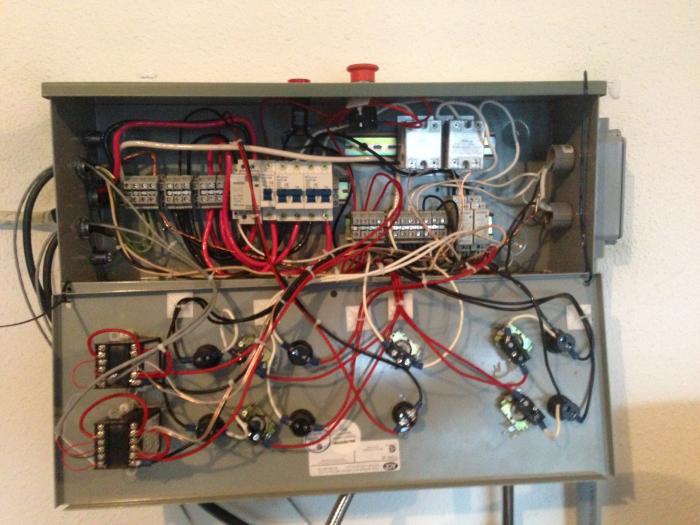

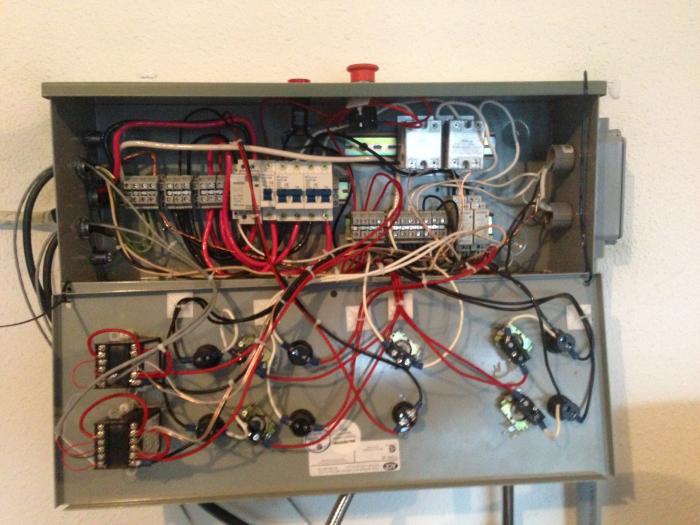

The control panel is based on a 50amp DIY kit purchased from ebrewsupply.com and I got the box for 20 bucks from the Habitat for Humanity ReStore. I know it looks like a rats nest, but essentially it is 2 MYPIN TA4 PIDs, connected to SSRs which power the elements, and then independant controls for the 2 pumps.

You will also see on the left of my set-up, my fermentation chamber (pics soon). I built an insulated box around a bar fridge. I am using a sanke keg as my fermenter, with a carboy heater attached to it. The entire chamber is controlled by a 2 stage controller, which allows for heating or cooling as neccessary.

I look forward to all your comments and questions

Finally I must give thanks to the HBT community for all the help during my build, especially Joe Fisher for manskirtbrewing.com. Also the following suppliers:

www.ebrewsupply.com

www.homebrewstuff.com

www.hopdawgs.ca

www.brewershardware.com

www.austinhomebrew.com

Cheers

Kevin

Here are the first pictures of my EHERMS setup. Just finished it last night, now I am in the process of testing it. So far, so good, should be ready for my first all-grain batch by the weekend!!

It is a 3 vessel, single tier system. I used 2 sanke kegs and 1 10gal bayou kettle. I have 2 march 815 pumps (you will notice that 1 of them has a stainless head, because I had an oops while plumbing, requiring me to buy a replacement). The Boil Kettle and HLT each have 5500w electric heating elements installed and are PID controlled. The MLT has an analog thermometer.

I used a stainless steel operating room cart as the stand.

The control panel is based on a 50amp DIY kit purchased from ebrewsupply.com and I got the box for 20 bucks from the Habitat for Humanity ReStore. I know it looks like a rats nest, but essentially it is 2 MYPIN TA4 PIDs, connected to SSRs which power the elements, and then independant controls for the 2 pumps.

You will also see on the left of my set-up, my fermentation chamber (pics soon). I built an insulated box around a bar fridge. I am using a sanke keg as my fermenter, with a carboy heater attached to it. The entire chamber is controlled by a 2 stage controller, which allows for heating or cooling as neccessary.

I look forward to all your comments and questions

Finally I must give thanks to the HBT community for all the help during my build, especially Joe Fisher for manskirtbrewing.com. Also the following suppliers:

www.ebrewsupply.com

www.homebrewstuff.com

www.hopdawgs.ca

www.brewershardware.com

www.austinhomebrew.com

Cheers

Kevin