Ciliorozo

Well-Known Member

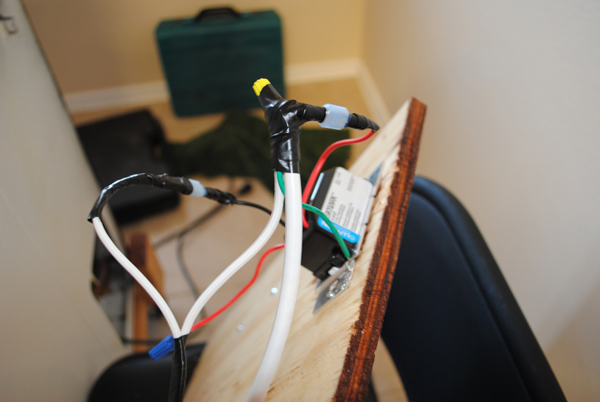

I have been meaning to pull a build thread together and after I had a few requests for one I decided to sit down and finally get it done. I will be posting a lot of photos. So without further ado here is my Jester Inspired Keezer. The Gator-ator!

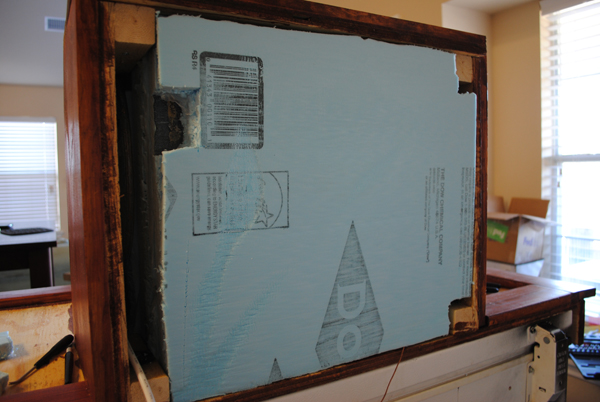

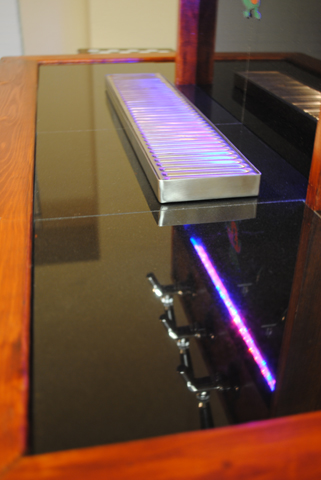

A brief synopsis on materials used: The table top and the tap box are structurally 19/32 Plywood. Then we put a layer of Hardwood (Whitewood) over the tap box and on the trim. Then we finished the top with Granite tile. The tap box is anchored to the table top using t-nuts and bolts, then the table top is anchored to the freezer lid using t-nuts and bolts as well as liquid nails.

All straight cuts were done with a circular saw and all angled cuts with a miter saw.

Lets start with a look at the finished product:

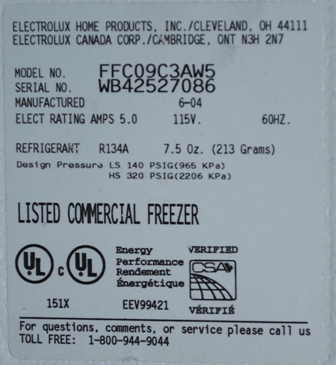

Here is where we started. My wife got me the greatest Birthday present a 3 Keg Kit! Plus a freezer and a bank of regulators.

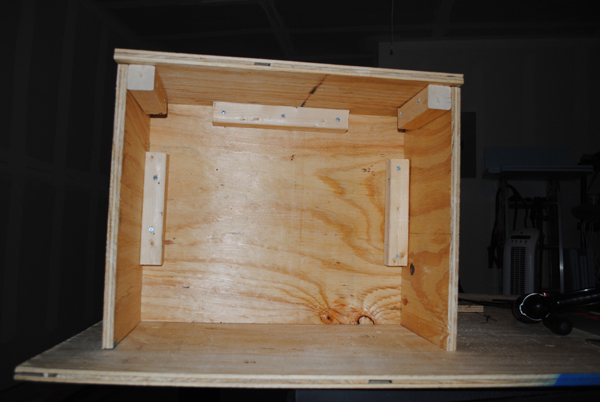

We then started with a single piece of 19/32 Plywood. In which we drew out the table top, plus the 4 sides to the tap box (Top, Left, Right, Front).

Cheers! Here's my wonderful wife saying "Lets get this thing started!"

A brief synopsis on materials used: The table top and the tap box are structurally 19/32 Plywood. Then we put a layer of Hardwood (Whitewood) over the tap box and on the trim. Then we finished the top with Granite tile. The tap box is anchored to the table top using t-nuts and bolts, then the table top is anchored to the freezer lid using t-nuts and bolts as well as liquid nails.

All straight cuts were done with a circular saw and all angled cuts with a miter saw.

Lets start with a look at the finished product:

Here is where we started. My wife got me the greatest Birthday present a 3 Keg Kit! Plus a freezer and a bank of regulators.

We then started with a single piece of 19/32 Plywood. In which we drew out the table top, plus the 4 sides to the tap box (Top, Left, Right, Front).

Cheers! Here's my wonderful wife saying "Lets get this thing started!"

I'm elbows deep in a keezer build myself. What a blast. I can't wait to finish up and start enjoyinf the fruits of my labor. If you get a chance, jump onto my thread in my signature line and check it out. I have received a bunch of PM's lately indicating that I should have started my Rustic keezer build in the DIY section instead of the kegging/bottling section. Oops! Live and learn. Again....your keezer is fantastic and I hope if brings you many years of enjoyment!

I'm elbows deep in a keezer build myself. What a blast. I can't wait to finish up and start enjoyinf the fruits of my labor. If you get a chance, jump onto my thread in my signature line and check it out. I have received a bunch of PM's lately indicating that I should have started my Rustic keezer build in the DIY section instead of the kegging/bottling section. Oops! Live and learn. Again....your keezer is fantastic and I hope if brings you many years of enjoyment!