Hey All!

I needs some ideas for improving my cooling system. I made a bit of an error in my design. I have a freezer with coolant in a bucket. I have temp sensors and controllers. Selenoid valves and stainless immersion chillers. The failed link is my submersible pump. I did not even consider the heat that thing puts off. My coolant only stays cold for about 15 minutes of running the system.

What are my options. I was thinking some other kind of continuous duty pump. It has to be strong enough to pump three lines with distances of up to 75 feet each line. plus the lines are 7 feet in the air.

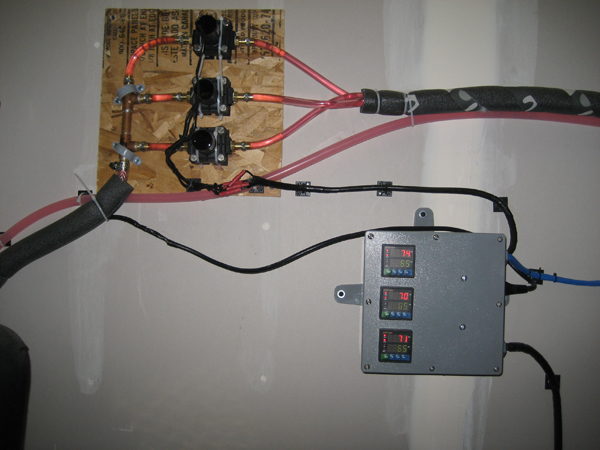

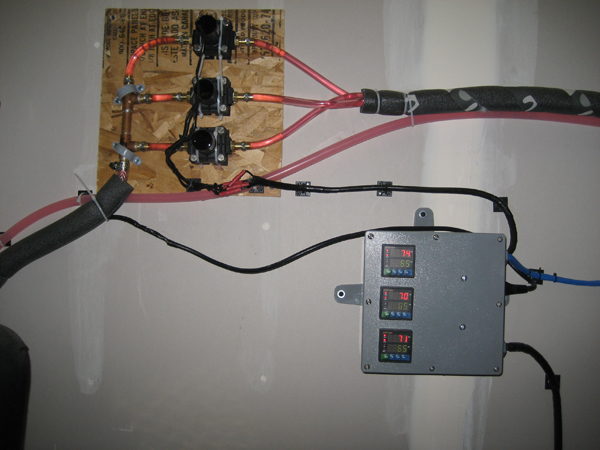

Here are a couple of pictures of what I have going so far.

I needs some ideas for improving my cooling system. I made a bit of an error in my design. I have a freezer with coolant in a bucket. I have temp sensors and controllers. Selenoid valves and stainless immersion chillers. The failed link is my submersible pump. I did not even consider the heat that thing puts off. My coolant only stays cold for about 15 minutes of running the system.

What are my options. I was thinking some other kind of continuous duty pump. It has to be strong enough to pump three lines with distances of up to 75 feet each line. plus the lines are 7 feet in the air.

Here are a couple of pictures of what I have going so far.

) to get where you want to go;

) to get where you want to go;