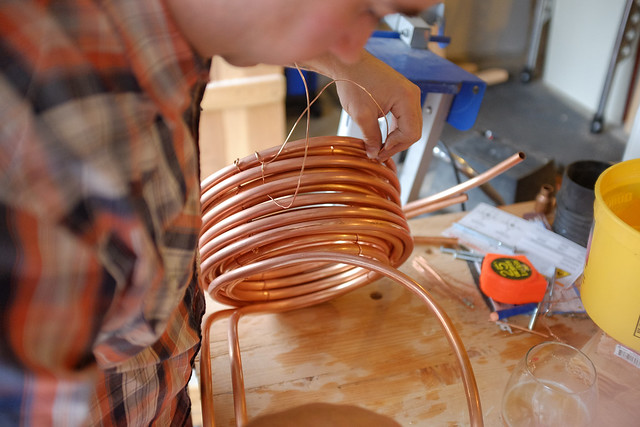

Here's my take on a chiller styled after the ones available from Jaded. This is made up of 3 20' lengths of copper tubing.

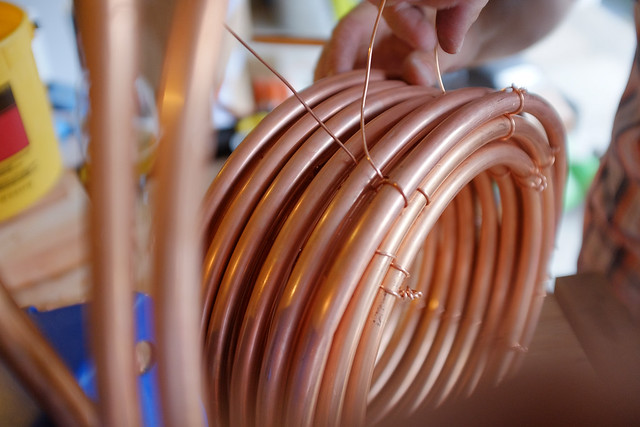

I used a 1 gallon bucket as a form, and I used some copper wire sourced from some leftover romex I had to tie it together.

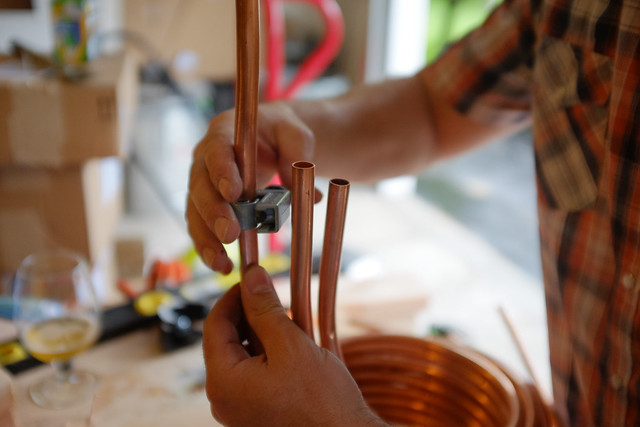

I tied the three pieces together with a 1" to 1/2" reducer I soldered to the ends, and then I sealed with silicon. I haven't leak tested yet. My backup plan is to create a manifold using a couple of T's and an elbow.

I don't have a tubing bender, so I wasn't able to get the two sides exactly where I wanted them, and I have one or two kinks, but I think this will work.

It is quite heavy, and I'm hopeful that it is quicker than my old setup (which was one 20' coil).

https://flic.kr/p/nEbSpt

https://flic.kr/p/nEbSpt

I used a 1 gallon bucket as a form, and I used some copper wire sourced from some leftover romex I had to tie it together.

I tied the three pieces together with a 1" to 1/2" reducer I soldered to the ends, and then I sealed with silicon. I haven't leak tested yet. My backup plan is to create a manifold using a couple of T's and an elbow.

I don't have a tubing bender, so I wasn't able to get the two sides exactly where I wanted them, and I have one or two kinks, but I think this will work.

It is quite heavy, and I'm hopeful that it is quicker than my old setup (which was one 20' coil).

https://flic.kr/p/nEbSpt

https://flic.kr/p/nEbSpt