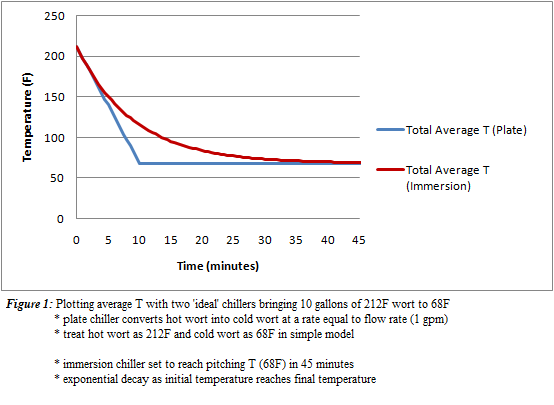

Okay, so I've set up a simple cooling model for a plate chiller and immersion chiller working on a 10 gallon batch.

The plate chiller converts 212F wort to 68F wort at a rate equal to its flow rate (gpm). I've set it for 1 gpm, which is

not unreasonable.

The immersion chiller starts at 212F and decays to 68F. I've picked a cooling coefficient so it does the job in 45 minutes - a number I got from a random post but seems good for my LHBS coil. This is highly dependent on the cooling water temperature so any compelling arguments from people of Antarctica have to be taken with a grain of salt.

These two models give temperature as a function of time and we see in Figure 1.

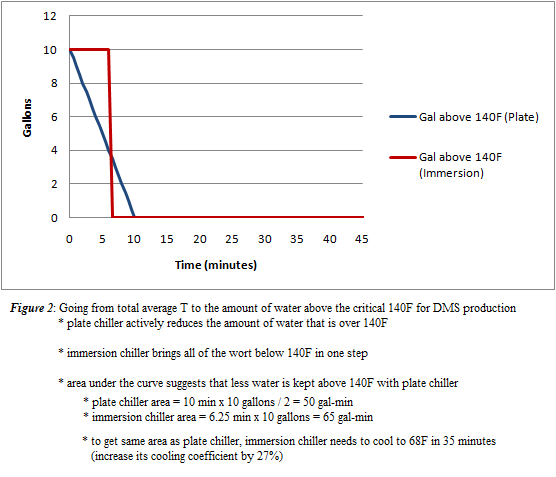

Average temperature doesn't tell the whole story for the plate chiller model - we're averaging two extreme temperatures. Figure 2 retells this as the volume of water above 140F (the cited/uncited critical temperature for DMS).

The area under the plots in Figure 2 is in gallon-minutes. The smaller this area the less water we have above this critical temperature for less time. The area of the IC plot (65 gal-min) is 30% higher than the PC plot (50 gal-min). For the two to be equal and the IC to start to exceed the PC in this respect, the IC would need to chill the 10 gallons in 35 minutes with a cooling coefficient 27% higher than the one I defined.

This doesn't take into account any complex relationships like the exact temperature dependence on DMS production (180F is as good as 150F in this case). In which case, we would need to put the area of those plots to some exponential function where higher temperatures are worse and worse (though that might not be the case).

An interesting note I read from that thread I linked in my last post is that keeping a portion of your brew at high temperature (in the plate chiller case) can allow for DMS to continue to boil off like it does in the boil. DMS is a small molecule and so keeping it at high temperatures and not warm temperatures like in the later stages of the IC would help to keep driving it off.

In that scenario, I could see an IC pushing the temperature into a region where the temp is too high to stop DMS production but too low to allow DMS to evaporate out efficiently. The PC would allow the bulk of the wort to remain in that high enough to evaporate DMS and then immediately get cooled bit by bit to halt DMS production in the cooled wort.