Can this pump handle hop pellets without any type of filtering device?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Has any one ever used this new pump?

- Thread starter bennihana

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

rgauthier20420

Well-Known Member

- Joined

- Sep 20, 2012

- Messages

- 771

- Reaction score

- 70

Can this pump handle hop pellets without any type of filtering device?

I would venture to say no, but I haven't tried. I don't think I would either.

I ordered a couple of them - I'll tell you what I think! I'm planning on making a portable wireless transfer skid.

Nearly a month after ordering and they're still not here...

Nearly a month after ordering and they're still not here...

From their ebay site:

"If you have not received your shipment within 30 business days from payment, please contact us. We will track the shipment and get back to you as soon as possible. Our goal is customer satisfaction!"

If it takes more than 35 days after ordering, you're supposed to get a refund.

HTH

Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

I live in Norway, Europe. China-stuff can take for ages to show up here if the timing is bad.

My guess is that they may "ship" the thing you ordered the same day or after, then your package is supposed to go on a container ship. If the ship just left the dock without your package then it will have to wait for the next ship designated for the container with your package.

I've been waiting from 2-6 weeks for stuff.

I've also heard that the ocean is a dangerous place due to lots of containers floating around.. I'd wait until the 30 day mark and send them an email. I got a DOA-pump once and they offered me a refund of 3/4 of the price I paid, that's because they don't want to refund the shipping costs, which are baked into the price (free shipping).

But, when they say "our goal is customer satisfaction" I've experienced that most of them really mean it. Most of them have a really tight business, moneywise, so I don't think they want to get bad rep or lose a customer.

My guess is that they may "ship" the thing you ordered the same day or after, then your package is supposed to go on a container ship. If the ship just left the dock without your package then it will have to wait for the next ship designated for the container with your package.

I've been waiting from 2-6 weeks for stuff.

I've also heard that the ocean is a dangerous place due to lots of containers floating around.. I'd wait until the 30 day mark and send them an email. I got a DOA-pump once and they offered me a refund of 3/4 of the price I paid, that's because they don't want to refund the shipping costs, which are baked into the price (free shipping).

But, when they say "our goal is customer satisfaction" I've experienced that most of them really mean it. Most of them have a really tight business, moneywise, so I don't think they want to get bad rep or lose a customer.

From their ebay site:

"If you have not received your shipment within 30 business days from payment, please contact us. We will track the shipment and get back to you as soon as possible. Our goal is customer satisfaction!"

If it takes more than 35 days after ordering, you're supposed to get a refund.

HTH

I ordered it 7/1

It's 7/29 now

I'll give it a few more days

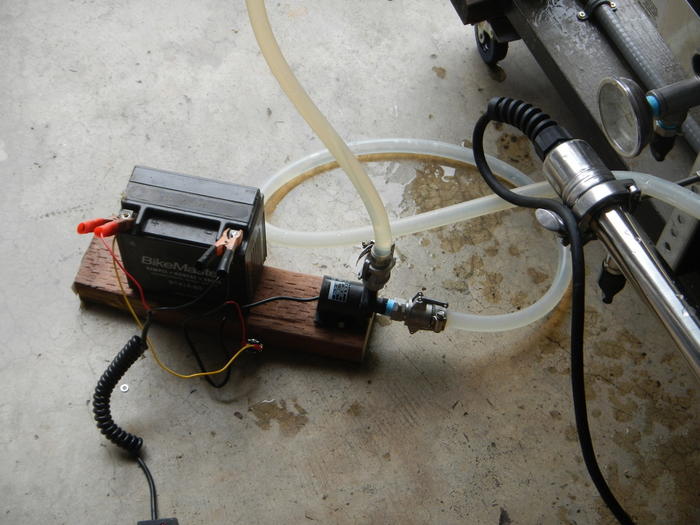

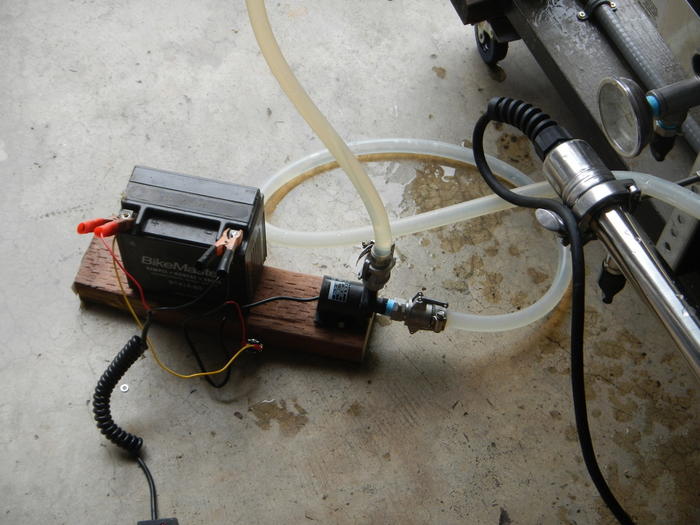

Got them yesterday! I'll set up a 10 gallon boil and pump the hot water through a chiller and test them. They look well made and have heft to them. The threads are a straight thread, but I can force a 1/2" npt on them.

OK - and initial test has been completed.

Items used:

1) old motorcycle battery - charged overnight

1) Associated wiring and switch

1) Trickle Charger for between tests

10) Gallons of water

It pumps ten gallons of 52f degree water in five minutes - I tested it twice and the results were seconds apart.

I measured 14" between the outlet and the bottom of the keggle I was pumping it into.

It's a very quiet pump.

Items used:

1) old motorcycle battery - charged overnight

1) Associated wiring and switch

1) Trickle Charger for between tests

10) Gallons of water

It pumps ten gallons of 52f degree water in five minutes - I tested it twice and the results were seconds apart.

I measured 14" between the outlet and the bottom of the keggle I was pumping it into.

It's a very quiet pump.

Overall first impressions are very positive, this is a nice pump. It is able to pump through my chiller at a reduced rate. The price is right but the shipping takes a LONG time. It'll be a good pump for transferring beer or other liquids.

I have two of these little pumps, and my first few experiences have been very positive as well.

I've used them to recirc at the end of mashing, keep liquid temps from stratifying during electric heating (both wort and water), recirculating during chilling, and transferring liquids from mlt to bk and bk to fermenter.

Overall they have worked great, the last time I used it some grains got stuck in the inlet section, next to the propeller, but it still pushed through although at a limited rate. I've been very happy w this pump...

I've used them to recirc at the end of mashing, keep liquid temps from stratifying during electric heating (both wort and water), recirculating during chilling, and transferring liquids from mlt to bk and bk to fermenter.

Overall they have worked great, the last time I used it some grains got stuck in the inlet section, next to the propeller, but it still pushed through although at a limited rate. I've been very happy w this pump...

Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

It's whirlpooling my kettle at 180f right now. Not sure how it would do with hops but pellet hops might be ok.

I did my initial tests with plain water, but with hops and wort it didn't cut the cheese. Instead of getting a more powerful pump my solution was to add a mount for my 809 at the BK and some QDs (same as Moorebeer but way cheaper straight from AliExpress). Saved me a bunch of cash going this route.

So a little more follow up. I've used this a few times now. I use it to sparge and to run wort through the chiller. Worked without any problem at all. I'm really pleased with the purchase and grateful to those on this thread in particular who helped me out.

Sent from my Rotary Phone using Magic.

Sent from my Rotary Phone using Magic.

orangehero

Well-Known Member

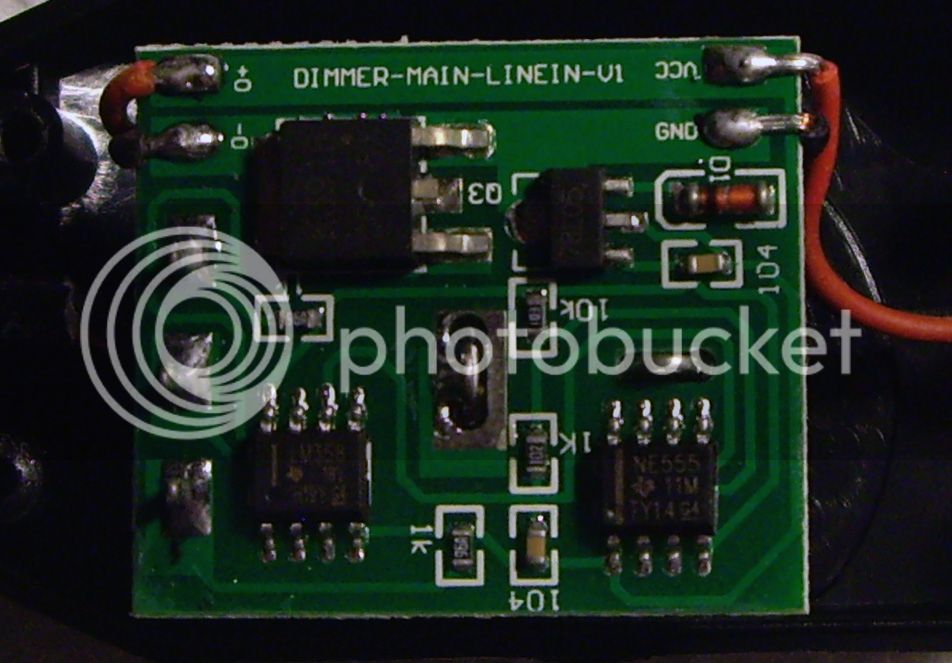

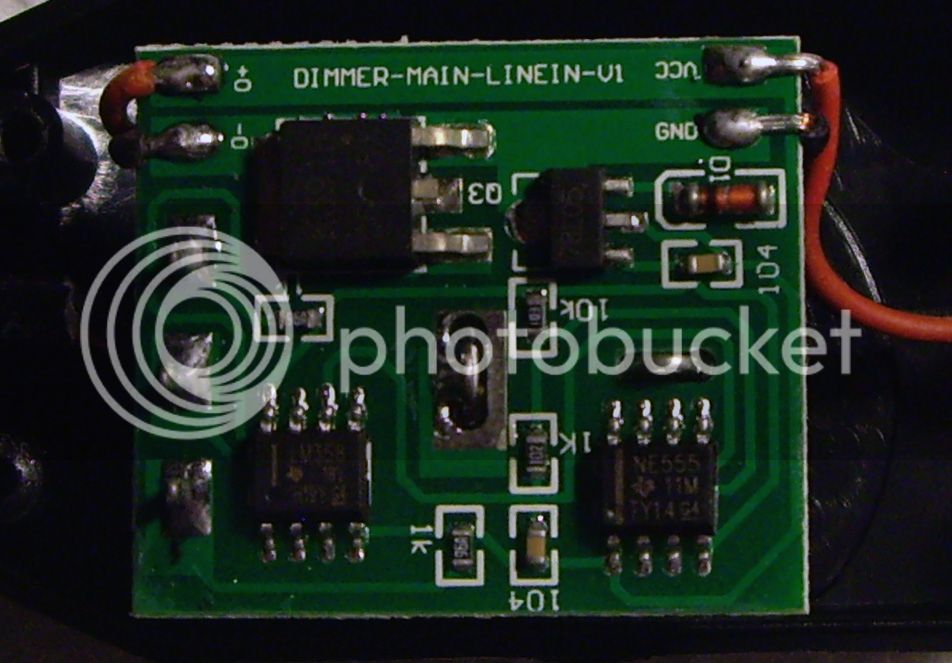

Any reason this wouldn't work to control output?

http://www.ebay.com/itm/Led-Wholesa...ing_Parts_and_Accessories&hash=item43cda5312f

http://www.ebay.com/itm/Led-Wholesa...ing_Parts_and_Accessories&hash=item43cda5312f

I don't see why it wouldn't work, and it's nice already having the plugs/connectors on it...this is the one I use for my pumps:

http://www.ebay.com/itm/171104731465

I plan to disassemble it and use the guts mounted in my control panel...

http://www.ebay.com/itm/171104731465

I plan to disassemble it and use the guts mounted in my control panel...

Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

It's a magnetic driven pump. You can just use a ball-valve on the output.

It's a magnetic driven pump. You can just use a ball-valve on the output.

I'm no expert on pumps, but from my experience limiting the output on my little pump seems to put a lot of strain on it, not that it purrs as nice/quietly running it at 50% vs 100% using the dimmer, but $3 for the dimmer that also has the ability to turn it off quickly was worth it in my opinion.

Minbari

Well-Known Member

- Joined

- Apr 29, 2014

- Messages

- 376

- Reaction score

- 61

I don't see why it wouldn't work, and it's nice already having the plugs/connectors on it...this is the one I use for my pumps:

http://www.ebay.com/itm/171104731465

I plan to disassemble it and use the guts mounted in my control panel...

As long as you dont exceed the 800mA limitation of the dimmer, you are golden. Most of those little DC "solar pumps" are in the area of 800-1200mA for 12Volts.

Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

I'm no expert on pumps, but from my experience limiting the output on my little pump seems to put a lot of strain on it, not that it purrs as nice/quietly running it at 50% vs 100% using the dimmer, but $3 for the dimmer that also has the ability to turn it off quickly was worth it in my opinion.

I don't think you'd put much strain on it.

Whenever the flow gets too tight the impeller will just "skip". Meaning the motor-shaft will spin as normal, but since it's magnetically coupled the resistance against the impeller will make the impeller not spin as fast as the shaft. When the resistance against the impeller is small enough the magnets will grab and the impeller will spin. The motor works as it should, either way. It's the motor you're worried about burning out.

This way the pump gets it rated voltage and amps all the time and is operated as according to its specs.

Correct me if i'm wrong, someone.

I don't think you'd put much strain on it.

Whenever the flow gets too tight the impeller will just "skip". Meaning the motor-shaft will spin as normal, but since it's magnetically coupled the resistance against the impeller will make the impeller not spin as fast as the shaft. When the resistance against the impeller is small enough the magnets will grab and the impeller will spin. The motor works as it should, either way. It's the motor you're worried about burning out.

This way the pump gets it rated voltage and amps all the time and is operated as according to its specs.

Correct me if i'm wrong, someone.

Yea, not trying to argue at all, but honestly from what I've read throttling the output via valve, using variable voltage power supplies, or a PWM device all are acceptable for DC pumps...I'm not an expert though as to what may be best for the life of the pump.

BUT.... With the LED dimmer I bought I got to play with my soldering iron to do this:

http://smokedprojects.blogspot.com/2013/09/led-dimmer-pwm-hack.html?m=1

Weezy

Well-Known Member

The beauty of 12V pumps is being able to use the PWM controller to vary flow rate. With a PWM you don't even need an on/off switch. Much better solution than a valve.

Ok I got the little tan pump and after one use I made a alteration. I made it so I can in screw the pump and leave the front part on my ball valve. It needed clean twice but that's because it was a pumpkin ale. But great little cheap pump!!!

Sent from my iPhone using Home Brew

Sent from my iPhone using Home Brew

orangehero

Well-Known Member

Here's the PCB of the inline LED dimmer. Possible to modify the capacitor?

Owly055

Well-Known Member

- Joined

- Feb 28, 2014

- Messages

- 3,008

- Reaction score

- 686

I'm using the tan version for my BIAB RIMS system. I haven't used it in real life yet, but I have used it in a full BIAB mash temp test. Flow is about perfect for my 2.5 gallon brews. Be careful with them..... this is a brittle plastic, and the castings are not very thick. I don't know what family of plastic they are, but I've had other stuff made from the same thing.

I have no reason to use this pump above 165F....... I use it ONLY for mash. I have no idea how it handles higher temps.

I run from an ATX computer power supply.....the standard one. To activate an ATX power supply, simply short the green wire to any black wire (ground). I grab old computers for the power supplies, and always have a few lying around. You can mount a toggle switch so you can kick it on and off. They provide superb 12 volt and 5 volt. I use them for electronics projects all the time. Good smooth DC.

H.W.

I have no reason to use this pump above 165F....... I use it ONLY for mash. I have no idea how it handles higher temps.

I run from an ATX computer power supply.....the standard one. To activate an ATX power supply, simply short the green wire to any black wire (ground). I grab old computers for the power supplies, and always have a few lying around. You can mount a toggle switch so you can kick it on and off. They provide superb 12 volt and 5 volt. I use them for electronics projects all the time. Good smooth DC.

H.W.

Ok I got the little tan pump and after one use I made a alteration. I made it so I can in screw the pump and leave the front part on my ball valve. It needed clean twice but that's because it was a pumpkin ale. But great little cheap pump!!!

Sent from my iPhone using Home Brew

Yea, I use a female camlock disconnect screwed on the inlet portion of my pump so I can connect directly to the bottom drain valve on my kettle, then I use a male camlock from my valves and can close the valve and move the pump to whatever vessel I need to transfer from...makes it very portable.

You can kind of tell what I mean in this pic...

Owly055

Well-Known Member

- Joined

- Feb 28, 2014

- Messages

- 3,008

- Reaction score

- 686

The beauty of 12V pumps is being able to use the PWM controller to vary flow rate. With a PWM you don't even need an on/off switch. Much better solution than a valve.

The beauty of centrifugal pumps is that you can vary the flow by simply throttling the outlet side. They are not positive displacement pumps, and as you throttle the flow, the power required goes down, not up as it would with a positive displacement pump......... There really is no reason to use a PWM controller............ a valve works just as well and is a lot simpler.

H.W.

Weezy

Well-Known Member

PWM works flawlessly for me and its cheaper than a valve and much more finely adjustable. But do what works for you.

After posting this thread months ago i have finally been able to test some things out! this is a great little pump but i wish it did have a little faster flow rate. but it is only a 12v .5 inch pump. It will still work perfectly for mashing.

augiedoggy

Well-Known Member

the black one mentioned in the first pump is not at all the same as the tan pumps... the black one is not built for food grade operation the tan one is. tan one has a coated magnet... black one has a bare magnet that comes into contact with food and different garde of plastic for the the pump housing...if you search this section of the forum you will find many threads breaking this down.

the topsflo pumpo is similiar to the black one mentioned here...I use both the tan and black one and have seen no ill effects of using the uncoated magnet on the black one yet...

they both have been working fine with my cheap ebay pwm controllers for almost a year now...

the topsflo pumpo is similiar to the black one mentioned here...I use both the tan and black one and have seen no ill effects of using the uncoated magnet on the black one yet...

they both have been working fine with my cheap ebay pwm controllers for almost a year now...

augiedoggy

Well-Known Member

I understand what your saying but with these 12v style pumps many people here have had the pumps fail and seize up by restricting the flow. the pwm controller seems to be less stressfull on the pump motorThe beauty of centrifugal pumps is that you can vary the flow by simply throttling the outlet side. They are not positive displacement pumps, and as you throttle the flow, the power required goes down, not up as it would with a positive displacement pump......... There really is no reason to use a PWM controller............ a valve works just as well and is a lot simpler.

H.W.

augiedoggy

Well-Known Member

I connect my pumps the same exact way... I use cheap shallow cake pans under where each pump connects to catch the little bit of spillage when disconnecting and moving the pumps about. works ok but I would still like to improve on it a bit.Yea, I use a female camlock disconnect screwed on the inlet portion of my pump so I can connect directly to the bottom drain valve on my kettle, then I use a male camlock from my valves and can close the valve and move the pump to whatever vessel I need to transfer from...makes it very portable.

You can kind of tell what I mean in this pic...

View attachment 221800

Similar threads

- Replies

- 2

- Views

- 3K

- Replies

- 5

- Views

- 1K

- Replies

- 8

- Views

- 1K