kenc_zymurgy

Well-Known Member

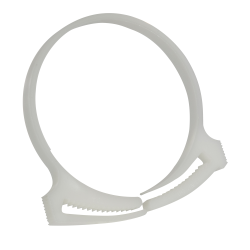

I'm working on a project I hope to share soon, but it involves attaching 1/4" ID vinyl hose to 1/4" OD stainless steel tubing. It will be subjected to room temperature carbonation pressures (possibly 60 PSI?) and I don't trust clamping the hose onto the smooth bore tubing.

My thoughts were to create some 'barbs' on the SS tube. I can get 5/16" OD SS that is just over 1/4" ID - I could silver solder (or lead free solder, I guess - I'll check the 'sticky' again later) a small ring of that 5/16" over the 1/4" to form a 'barb', and then clamp behind that 'barb'. Or maybe a 1/4" copper ferrule would do (coated with solder)? Or maybe rings of X gauge copper wire wrapped and soldered to from a barb?

This connection would not need to be removed, so I'm also thinking of adding a bit of aquarium silicone to the connection. Hose clamp behind the 'barb' after curing.

Those are my ideas, but maybe this has been tackled before and I'm missing the obvious. Any thoughts? Will my ideas work? Are there better/simpler approaches?

TIA - kenc

My thoughts were to create some 'barbs' on the SS tube. I can get 5/16" OD SS that is just over 1/4" ID - I could silver solder (or lead free solder, I guess - I'll check the 'sticky' again later) a small ring of that 5/16" over the 1/4" to form a 'barb', and then clamp behind that 'barb'. Or maybe a 1/4" copper ferrule would do (coated with solder)? Or maybe rings of X gauge copper wire wrapped and soldered to from a barb?

This connection would not need to be removed, so I'm also thinking of adding a bit of aquarium silicone to the connection. Hose clamp behind the 'barb' after curing.

Those are my ideas, but maybe this has been tackled before and I'm missing the obvious. Any thoughts? Will my ideas work? Are there better/simpler approaches?

TIA - kenc