SweetSounds

Well-Known Member

I'm getting ready to start buying parts for my AG rig. I have the funds at the moment, so it just seems like time to pull the trigger. The trouble is I haven't picked a process yet - It's confusing! The cart is WAY before the horse here...

These things I know for sure (Not much, I know):

It'll be electric - I've got a 50 amp service available, and I don't like gas.

I'll be making 10 gallon batches, and I like high-gravity beer

The B20 is cool, but I'm not very fond of having a bunch of hardware in my BK. So that leaves me with a 3 vessel system as my only option for any flavor of HERMS (Right?). The trouble is I just can't bring myself to spend $400 on another Boilermaker just to heat water.

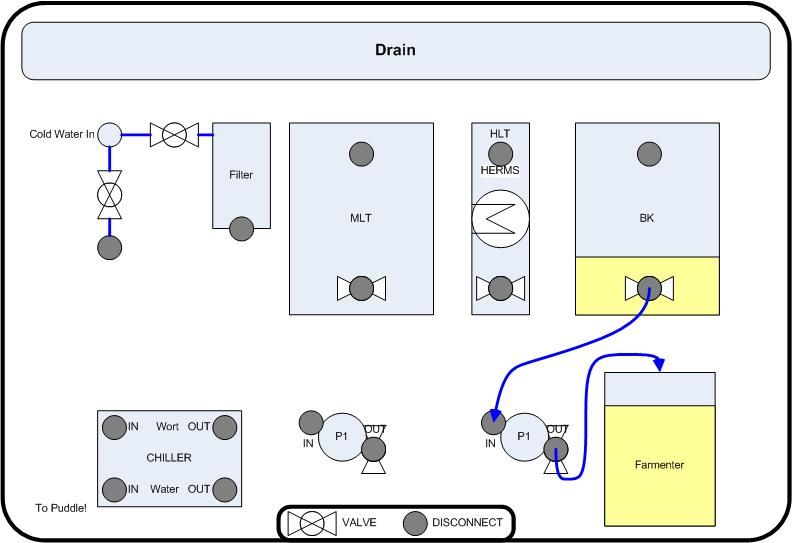

So this is the 3 vessel single tier design I have in my head...

BK - 20 Gallon, Bare bones, 5500w heat

MLT - 20 Gallon, False bottom, no heat

HLT/HERMS - 5 Gallon Corny, 5500w, Autosparge(ish) top off

2 pumps

2 PIDs

Custom automation, after I get to a process and results I like.

I plan to make 10 gallon batches, but like people say here, go bigger. The 20 gallon Boilermakers are $30 more than the 15, so why not right?

I figure strike water can be heated in the BK and pumped to the MLT, because the HLT is too small to heat the full strike volume.

Then I'll re-circulate through HERMS in the corny during the mash.

But I get lost at sparging... Is a 5 gallon HLT enough? If it's not, at a runoff rate of about a quart per minute the element will have to raise a quart of water about 110 degrees every 60 seconds - Hmmm...

Thoughts?

These things I know for sure (Not much, I know):

It'll be electric - I've got a 50 amp service available, and I don't like gas.

I'll be making 10 gallon batches, and I like high-gravity beer

The B20 is cool, but I'm not very fond of having a bunch of hardware in my BK. So that leaves me with a 3 vessel system as my only option for any flavor of HERMS (Right?). The trouble is I just can't bring myself to spend $400 on another Boilermaker just to heat water.

So this is the 3 vessel single tier design I have in my head...

BK - 20 Gallon, Bare bones, 5500w heat

MLT - 20 Gallon, False bottom, no heat

HLT/HERMS - 5 Gallon Corny, 5500w, Autosparge(ish) top off

2 pumps

2 PIDs

Custom automation, after I get to a process and results I like.

I plan to make 10 gallon batches, but like people say here, go bigger. The 20 gallon Boilermakers are $30 more than the 15, so why not right?

I figure strike water can be heated in the BK and pumped to the MLT, because the HLT is too small to heat the full strike volume.

Then I'll re-circulate through HERMS in the corny during the mash.

But I get lost at sparging... Is a 5 gallon HLT enough? If it's not, at a runoff rate of about a quart per minute the element will have to raise a quart of water about 110 degrees every 60 seconds - Hmmm...

Thoughts?