lewybrewing

Well-Known Member

I live in a condo, luckily I have a 2 car garage for brewing and storing other items for my hobbies. But I have never been that into controlling my temps during fermentation. Part of the problem is that I live in San Diego and I brew my beers to match the seasons. Once and a while I would use my portable cooler and some frozen water bottles. But I'll be honest, it was a pain in the ass.

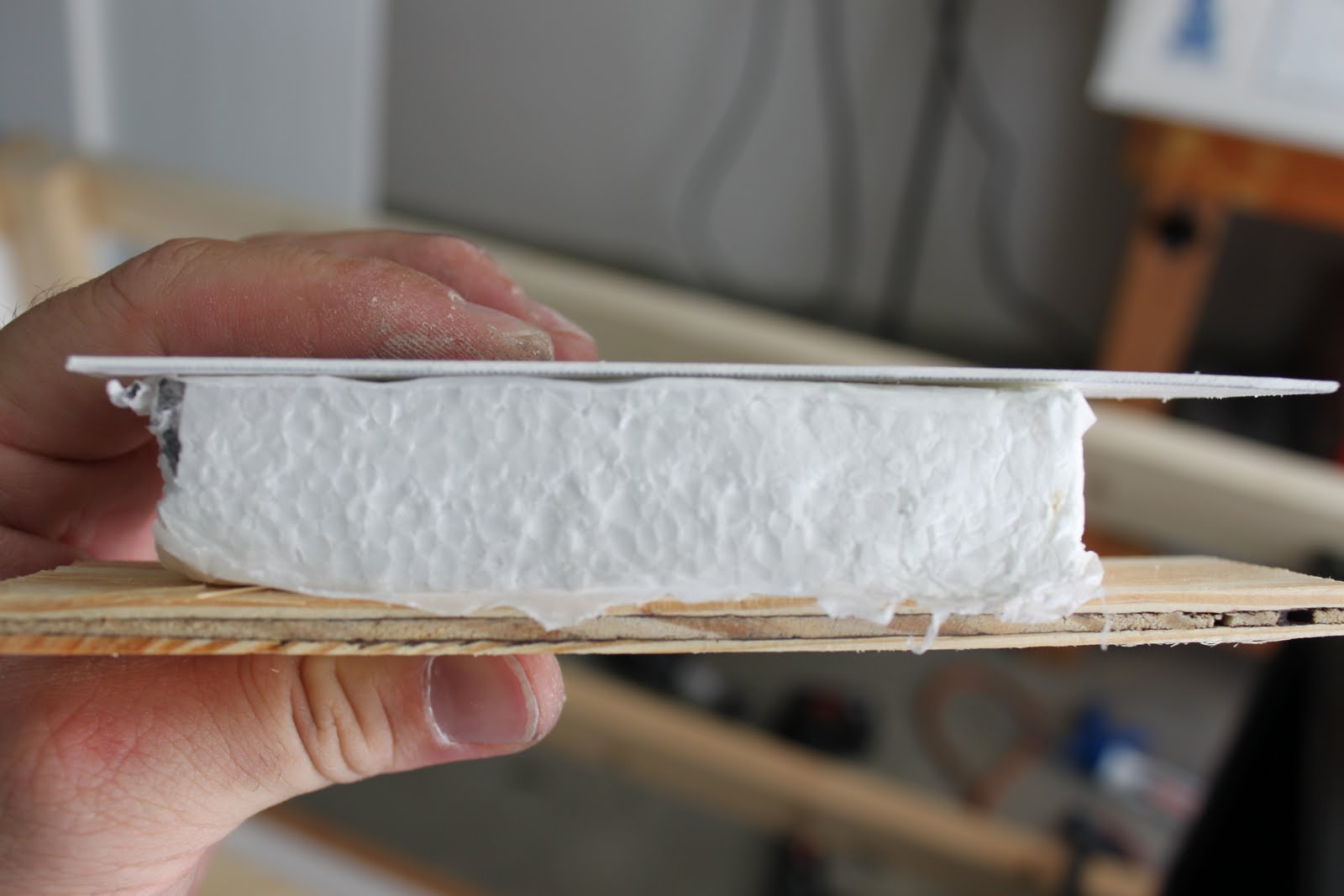

With the hot weather and scoring a free mini fridge from work it was time to build a temp controlled fermentation chamber.

The NEEDS:

1- To work.

2- Hold a least 3 full (6.5g) carboys

3- Also be a work bench on top.

4- Be airtight

The WANTS:

1- To look good

2- Have carboy information written on it. (Whiteboard or paint)

I am starting with a black and fake stainless steel door mini fridge. It is a sanyo with the freezer on top. The freezer door will be removed and I am installing 2 CPU fans for air circulation.

With the hot weather and scoring a free mini fridge from work it was time to build a temp controlled fermentation chamber.

The NEEDS:

1- To work.

2- Hold a least 3 full (6.5g) carboys

3- Also be a work bench on top.

4- Be airtight

The WANTS:

1- To look good

2- Have carboy information written on it. (Whiteboard or paint)

I am starting with a black and fake stainless steel door mini fridge. It is a sanyo with the freezer on top. The freezer door will be removed and I am installing 2 CPU fans for air circulation.