blackheart

Well-Known Member

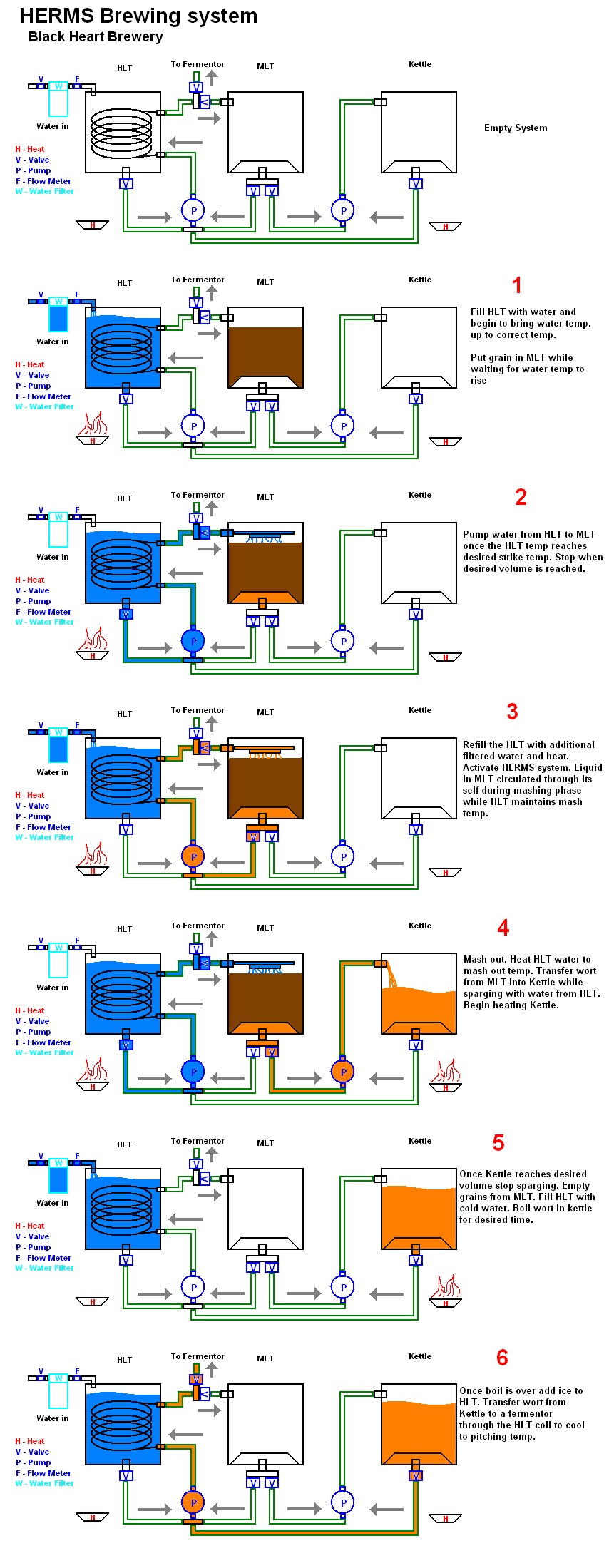

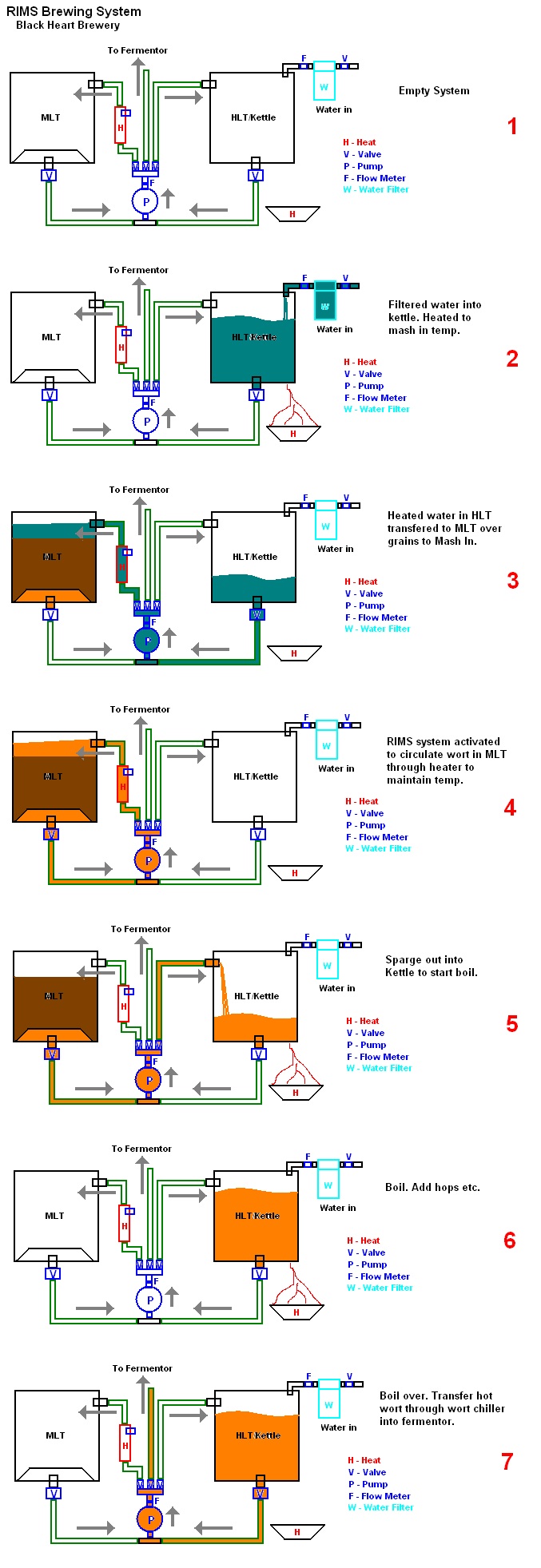

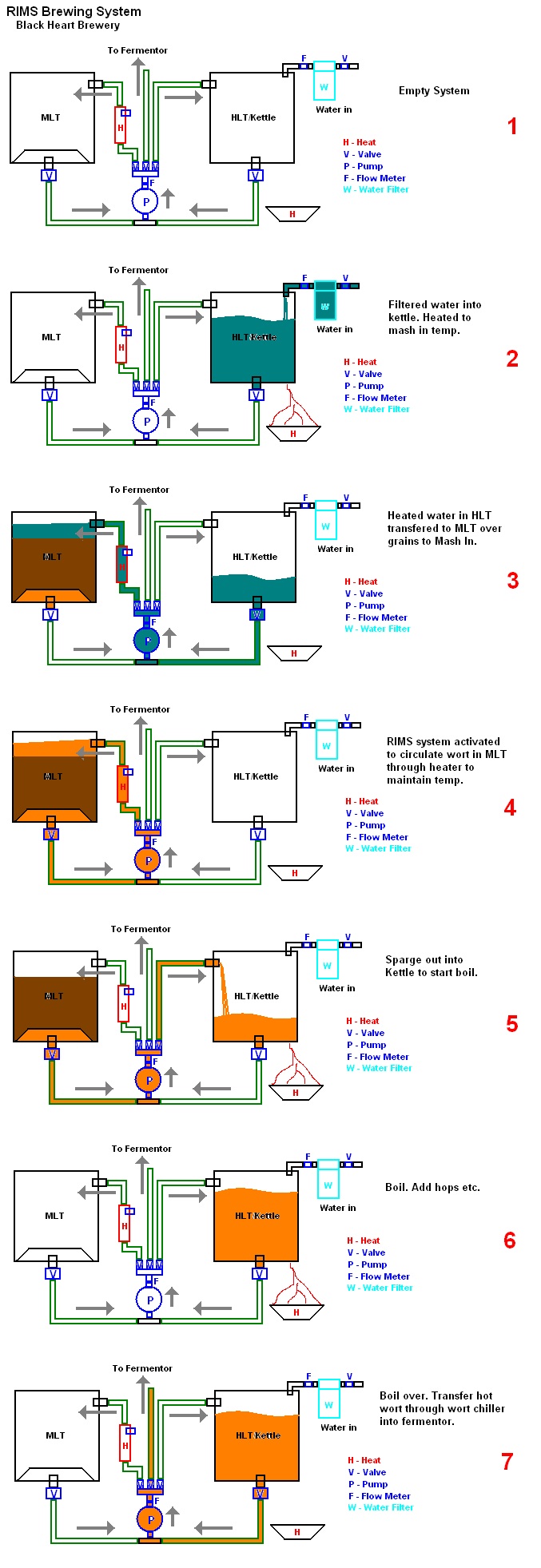

I have been working on a 10 gallon brewing system design and I want to plan everything out before I start buying parts etc.

Here is what I want to end up with. 10 gallon output, all grain, electronically controlled, as simple and efficient as possible.

I am looking at building a RIMS system using only two pots. Only 1 pot needs to be heated (gas or electricity, havent decided)

Here is what I laid out as the step by step process to try to see if I had things connected right and the process laid out the right way.

So with this in mind I have a few questions.

1. Am I missing something?

2. Can this be made more simple that it is (without removing the key pieces like electronic control)?

3. Recommendations on heating the HLT/kettle, only one pot needs to be heated in this case, and much of the system is already electric. Natural Gas is the only other option available.

4. Can anyone make part recommendations for the electronic valves and some kind of flow meter that can handle the high beer temps?

Please feel free to leave any comments or suggestions. (yes I know I can do all grain easier than RIMS etc but I am looking to build complete automated control and therefor need as few hose changes, part swapping etc as possible. )

Here is what I want to end up with. 10 gallon output, all grain, electronically controlled, as simple and efficient as possible.

I am looking at building a RIMS system using only two pots. Only 1 pot needs to be heated (gas or electricity, havent decided)

Here is what I laid out as the step by step process to try to see if I had things connected right and the process laid out the right way.

So with this in mind I have a few questions.

1. Am I missing something?

2. Can this be made more simple that it is (without removing the key pieces like electronic control)?

3. Recommendations on heating the HLT/kettle, only one pot needs to be heated in this case, and much of the system is already electric. Natural Gas is the only other option available.

4. Can anyone make part recommendations for the electronic valves and some kind of flow meter that can handle the high beer temps?

Please feel free to leave any comments or suggestions. (yes I know I can do all grain easier than RIMS etc but I am looking to build complete automated control and therefor need as few hose changes, part swapping etc as possible. )