ernestmyname

Well-Known Member

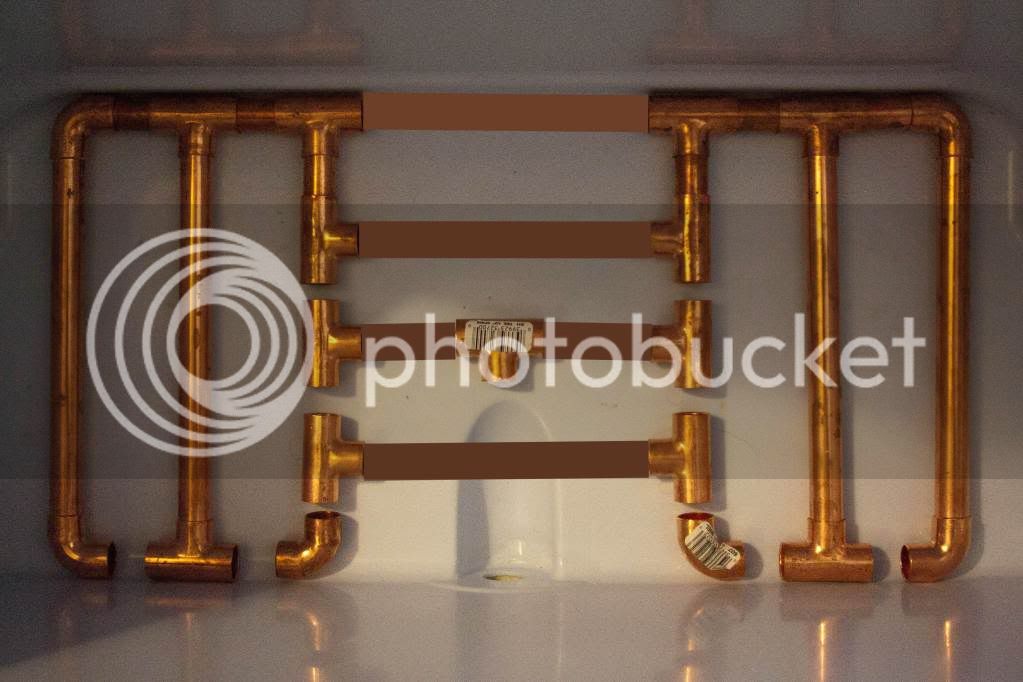

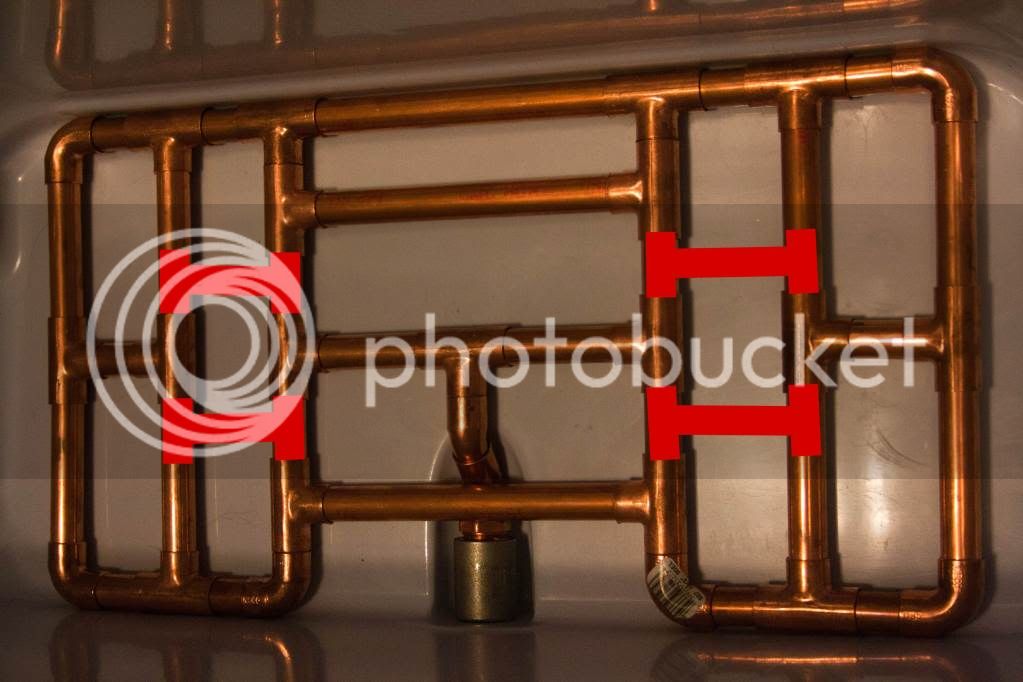

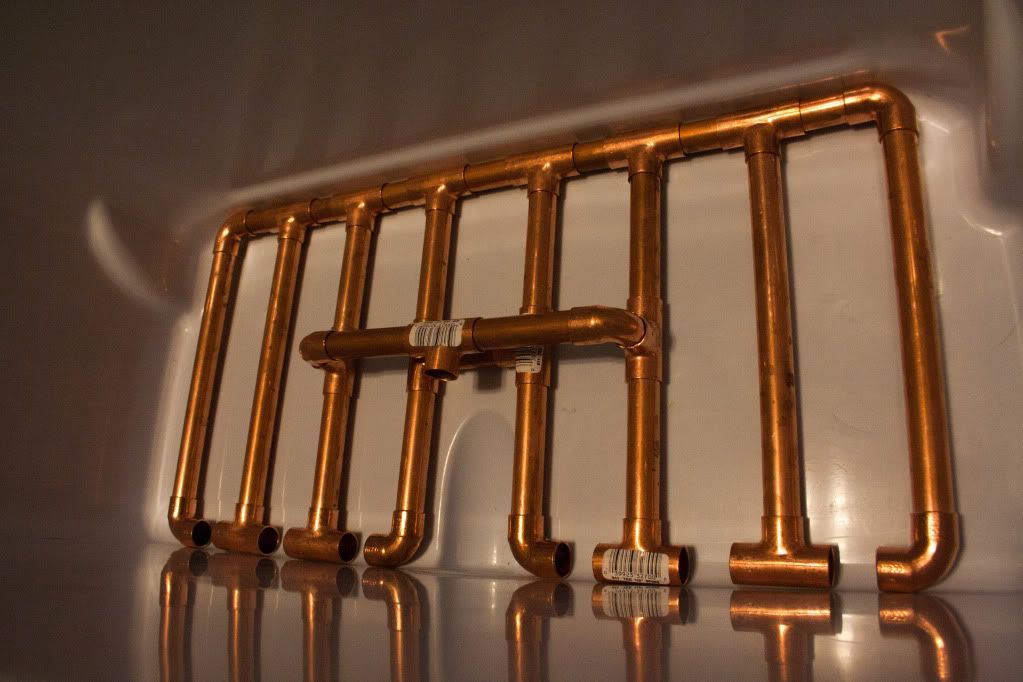

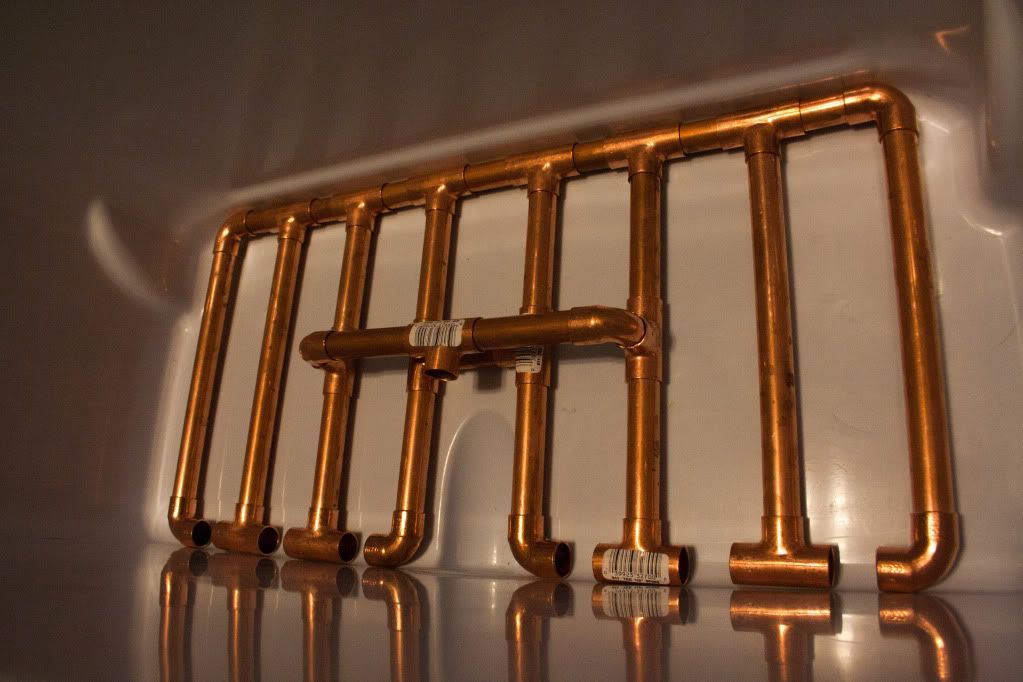

I was given this rectangular cooler and am considering using this setup for my mash tun manifold. It isn't official but I was wondering what you guys think. Cost really isn't an issue since I got to return my 10 gallon igloo cooler!  I really wanted to incorporate two different drain locations, thinking that it would make the draining a little more uniform. The only downside to this setup I can see is I will have to solder the joints to ensure a good siphon. Otherwise, I will lose a lot of wort at the end of the drain. It will also be more difficult to get that last little bit of wort out the grain. Thoughts?

I really wanted to incorporate two different drain locations, thinking that it would make the draining a little more uniform. The only downside to this setup I can see is I will have to solder the joints to ensure a good siphon. Otherwise, I will lose a lot of wort at the end of the drain. It will also be more difficult to get that last little bit of wort out the grain. Thoughts?

BTW, to clarify, I planned to connect the drain tube to the exposed T fitting pictured. Possibly with high temp tubing to allow it to be connected and disconnected easily.

To clarify further, the fittings on the closest side have not been populated with the connecting pipes.

I really wanted to incorporate two different drain locations, thinking that it would make the draining a little more uniform. The only downside to this setup I can see is I will have to solder the joints to ensure a good siphon. Otherwise, I will lose a lot of wort at the end of the drain. It will also be more difficult to get that last little bit of wort out the grain. Thoughts?

I really wanted to incorporate two different drain locations, thinking that it would make the draining a little more uniform. The only downside to this setup I can see is I will have to solder the joints to ensure a good siphon. Otherwise, I will lose a lot of wort at the end of the drain. It will also be more difficult to get that last little bit of wort out the grain. Thoughts?

BTW, to clarify, I planned to connect the drain tube to the exposed T fitting pictured. Possibly with high temp tubing to allow it to be connected and disconnected easily.

To clarify further, the fittings on the closest side have not been populated with the connecting pipes.